Here's a quick means to determine MeOH injection to inhibit hydrates

This article proposes a set of reference charts developed by the authors for determining required methanol concentrations in the aqueous phase (rich solution) and total lean inhibitor's flow rate for a desired depression in hydrate formation temperature of a wet natural gas.

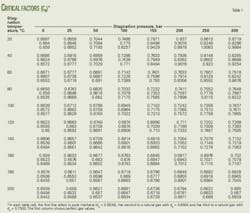

The charts were generated for 100 wt % MeOH and pressures of 3 MPa (about 435 psi), 5 MPa, 7 MPa, and 9 MPa based on ProMax and for a natural gas mixture with relative density of 0.6 but are extended to gases with relative densities up to 0.8 by use of two correction factors. A simple equation extends the charts' use to other lean MeOH concentrations.

Known data, results

Flowing gas temperature = 40° C.

Hydrate-formation temperature = 17° C.

Flowing gas pressure = 8 MPa

Density (specific gravity) = 0.60

Inhibitor = 100 wt % MeOH

Minimum flowing temperature = 5° C.

HFT depression = HFT – MFT = 17 – 5 = 12° C.

Results obtained by these charts are compared here with results of other methods for a practical case; good agreement is obtained. The authors also suggest that linear interpolation can be used for pressures between 3, 5, 7, and 9 MPa.

Hydrates in operations

Formation of hydrates in natural gas processing units and pipelines can cause shutdowns and even destruction of valuable equipment. Because of these often costly consequences, methods have been applied to prevent hydrate development in gas streams.

Conditions that tend to promote hydrate formation include low temperature, high pressure, and a gas at or below its water dewpoint temperature with "free" water present. Formation of hydrates can be prevented by any of the following techniques:

• Adjusting the temperature above and pressure below the hydrate formation condition, which may not be practically possible for economic or operational reasons.

• Dehydrating a gas stream with solid desiccant or glycol dehydration to prevent a free-water phase.

• Impeding hydrate formation in the free-water phase by injection of an inhibitor. The most common inhibitors are methanol, monoethylene glycol, and diethylene glycol. Typically, MeOH is used in a nonregenerable system, while MEG and DEG are used in regenerable processes.

The injected inhibitor may distribute into three possible phases:

- Vapor hydrocarbon phase.

- Liquid hydrocarbon phase.

- Aqueous phase, in which hydrate inhibition occurs, and the inhibitor affects the hydrate-formation condition. Therefore, calculating the inhibitor concentration in aqueous phase and total lean inhibitor injection rate are important.

Models

There are several models for predicting hydrate formation in the presence of an inhibitor. Correlations developed by Hammerschmidt, Nielsen and Bucklin, Carroll, and Moshfeghian-Maddox1-4 predict concentration of inhibitors in an aqueous solution and lower the hydrate-formation temperature.

Portability and simplicity are advantages of these correlations because they are applicable even with a simple calculator, and the results are in good agreement with the experimental data.1-4 It is to be noted that simulation packages such as ProMax,5 HYSYS,6 and GCAP7 are available for predicting the effect of inhibitors on hydrate formation.

The injection rate is a function of feed-gas temperature, pressure, relative density, hydrate formation temperature depression, and lean solution concentration. Recently, the authors proposed a shortcut, graphical method to predict the required MEG or MeOH weight percent and flow rate for a desired depression in hydrate temperature of natural gas mixtures.8 9

This article will demonstrate how the diagrams can be used to determine the concentration of MeOH in the rich solution and the required total injection rate for a desired depression of hydrate-formation temperature.

The graphs in Fig. 1 apply for any wet natural gas mixture with specific gravity of 0.6. Note that the right hand y-axis represents the total injection rate of MeOH that may distribute into gas phase, liquid hydrocarbon phase, and rich solution phase.

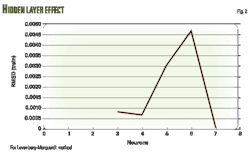

Extending the application of these charts to gas mixtures with other specific gravities requires two correction factors W1 and W2. These factors are used to correct the inhibitor concentration in the rich solution for other relative densities (0.65-0.80) that appear in Fig. 2.

W1 is the correction factor due to the difference of inhibitor concentration in the rich solution in different hydrate-formation temperature depression. This factor is applicable for gas with specific gravities greater than 0.6.

W2 is the correction factor due to the difference in inhibitor concentration in the rich solution due to the difference in gas specific gravities. To determine W2, the S-factor is defined as shown in Equation 1 in the accompanying box.

Calculating the S-factor allows W2 to be easily read from Fig. 2. This correction factor is applicable for gas with specific gravities of 0.65 and greater.

Using W1 and W2 in Equations 2 and 3 corrects the obtained weight percent from the charts in Fig. 1 (Wtfig).

Using the flow rate correction factor (FLC) found in Fig. 3 corrects the obtained flow rate from charts (Fig. 1). The correction factor can be applied as shown in Equations 4 and 5.

With these correction factors, the charts are applicable for natural wet gases with specific gravities of 0.6-0.8 saturated at temperature of 20, 30, 40, and 50° C. and pressures of 3, 5, 7 and 9 MPa.

As mentioned earlier, the inhibitor in the aqueous phase (rich solution) affects the hydrate-formation condition and is independent of the inhibitor weight percent in the lean solution. The same hydrate temperature depression is achieved when there is a similar inhibitor weight percent in the rich solution. However, the injection rate is a function of both lean and rich stream concentration.

Therefore, a simple material balance gives Equation 6.

Case study

A demonstration of the proposed charts employs Example 6.6 from Campbell's Gas Conditioning and Processing.10

This example states that 3.5 million std. cu m/day of natural gas leaves an offshore platform at 40° C. and 8,000 kPa. The hydrate temperature of the gas is 17° C. The gas arrives ashore at 5° C. and 6,500 kPa. The associated condensate production is 60 cu m/1 million std. cu m. The amount of methanol required to prevent hydrate formation in the pipeline is to be estimated.

It should be noted that in this example the composition (or relative density) of natural gas is not given. To demonstrating the use of these charts, therefore, one assumes a relative density of 0.6. With the feed-gas pressure at 8 MPa, a linear interpolation between 7MPa (Fig. 1c) and 9 MPa (Fig. 1d) is applied.

The summary of known data appears in the accompanying box on p. 54.

The presence of uncertainties in all inhibitor injection calculation methods prompts a safety factor to be applied to the hydrate-formation temperature depression. For example, this case has the HFTD set to the minimum flowing temperature. In practical situations, a design factor such as 2.8° C. (5° F.) below the MFT is used to ensure any errors in the estimation method are covered and also to ensure that the minimum temperature includes any upset process condition.

As an example, Fig. 1d shows the location of HFTD, required weight percent, and the total injection rate of MeOH for pressure of 9 MPa for this example. The results are tabulated in Table 1, and Table 2 compares the results of this work with those based on the Hammerschmidt1 equation, ProMax, HYSYS, and GCAP.

As can be seen from Table 2, agreement between the graphical method and ProMax is quite good. The methanol injection rates as estimated by HYSYS are significantly lower than the other methods, and caution should be applied in using HYSYS for inhibitor injection estimates. It is likely that the differences in the natural gas water dewpoint predictions are the result of this discrepancy.

Also note for modeling methanol liquid systems in process simulators, a polar equation-of-state package for the vapor phase and a polar model for the liquid phases must be selected to obtain accurate results.

References

- Hammerschmidt, E.G., "Formation of gas hydrates in natural gas transmission lines," Ind. & Eng. Chem., Vol. 26 (1943), p. 851.

- Nielsen, R.B., and Bucklin, R.W., "Why not use methanol for hydrate control," Hydrocarbon Processing, Vol. 62, No. 4 (April 1983), p. 71.

- Carroll, J., Natural Gas Hydrates: A Guide for Engineers, Gulf Professional Publishing, 2nd Edition 2009, p. 119.

- Moshfeghian, M., and Maddox, R.N., "Method predicts hydrates for high-pressure gas stream," OGJ, Aug. 30, 1993, p. 78.

- ProMax, V. 2.0, Bryan, Tex.: Bryan Research & Engineering Inc, 2007.

- HYSYS, V. 2006, Cambridge, Mass.: Aspen Technology Inc., 2006.

- GCAP, Facilities Analysis Software, 8th Ed., Norman, Okla.: John M. Campbell & Co., 2009.

- Moshfeghian, M., and Taraf, R., "New method yields MEG injection rate," OGJ, Sept. 1, 2008, p. 44.

- Moshfeghian, M., and Taraf, R., "A new shortcut/graphical method to determine the required MEG injection rate for natural gas hydrate inhibition," 87th Annual Gas Processors Association Convention Mar. 2-5, 2008, Grapevine, Tex.

- Campbell, J.M., Gas Conditioning and Processing, Vol. 1, The Basic Principles, 7th Ed., p. 193, Norman, Okla.: J.M. Campbell & Co., 1994.

The authors