Well off Mexico illustrates various drilling, completion complications

A well recently drilled off Mexico, Bolontiku 43, provides an example of numerous drilling problems encountered when drilling tectonically active zones that included extensive faulting, salt zones, clay and shale problems, loss circulations, and high-pressure zones over or underlain by low-pressure zones.

Pemex’s Bolontiku field is in Mexico’s southwest marine regions of the Gulf of Mexico (Fig. 1).

Fig. 2 shows the planned structural section of the well that includes the Upper Cretaceous, Middle Cretaceous, and top of the Upper Jurassic–Kimmeridgiano.

Before drilling, the extensive planning process for Bolontiku 43 included geoscience studies to determine the best operating window, taking into considerations the complicated and tectonically active zones within the area (Fig. 3)

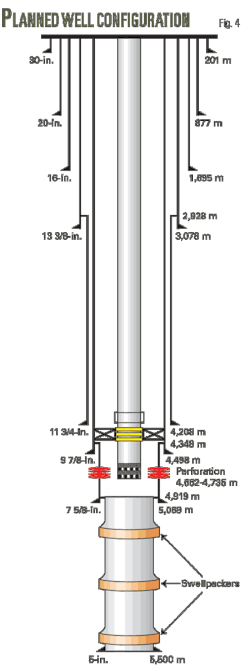

Fig. 4 shows the planned well configuration.

Drilling highlights

The first part to the drilling operation set the 30 and 20-in. casings at planned depths but problems appeared during drilling of the 171⁄2-22-in. hole, in which the plans called for setting 16-in. casing over the first fault. The drilling below 1,100 m experienced severe high torques, vibrations, and several fishing jobs for twisted off bottomhole assemblies.

These problems did not occur during drilling of previous offset wells.

Cementing of the 16-in. casing set at 1,690 m encountered lost returns, no cement at surface, and required a top cement job.

After setting of the 16-in. casing, the drilling plan called for increasing mud weight to 2 g/cc from 1.37 g/cc in a 105⁄8-in. hole followed by opening the hole to 171⁄2-in. with a 141⁄2-171⁄2-in. step hole opener and setting 133⁄8-in. casing at 3,078 m.

The plan also called for kicking off and building up angle in this zone, so that drilling of this section required steerable bottomhole assemblies.

Drilling of the 105⁄8-in. hole proceeded to 2,467 m with few torque and vibration events. Increases in mud weight to 2.04 from 2.00 g/cc ensured wellbore stability but caused light partial mud losses.

The well, however, acted strangely during opening of the hole to 171⁄2 in. When gas-cut mud surfaced at 2,467 m, the assumption was that the well had kicked. This led to increasing the mud weight to 2.06 g/cc.

The hole, nevertheless, continued to act strangely, at times losing mud, suggesting a thief zone, yet other times gaining mud in the surface mud tanks, suggesting a kicking well with gas cut mud to surface, gas to surface, or high combustible gas reading at surface with increased mud salinity. This dynamic gain and loss situation persisted.

Attempts for controlling the well while drilling did not work, yet under static conditions, the well, even with the blowout preventers open, remained stable.

Shut-in drill pipe pressure and shut-in casing pressures did not suggest a well that was kicking.

Circulation of the well, after awhile, began returning large formation cuttings to the shale shakers. These cuttings plugged the drillstring and choke manifold at surface.

The two offset wells, Bolontiku-2, only 67 m away, and Bolontiku 41, only 41 m away, did not experience such problems.

The seismic section adopted in drilling plan showed no anomalies (Fig 5). A pumped cement plug shut off the well, however, the gain and loss dynamic recurred upon drilling out the cement plug.

To avoid this zone, the operator decided to sidetrack the well. The sidetrack involved setting a cement plug in the open hole and side tracking at 1,715 m. Directional surveys, however, suggested that the well would not sidetrack and was still in the disturbed zone. The buildup rate and azimuth failed to achieve the desired departure from the old wellbore.

The peculiar drilling behavior experienced in the drilling indicated that supercharging or ballooning of the formation might have caused the delays experienced during drilling of the 171⁄2-in. hole with a 105⁄8-in. bit and 141⁄2-171⁄2-in. step hole openers.

The 133⁄8-in. casing was set at 3,068 m under uncontrolled well conditions. The cement job of the casing was questionable.

Drilled below the 133⁄8-in. was a 121⁄4-in. hole to 4,166 m. A hole opener enlarged the hole to 143⁄4 in.; the well’s peculiar behavior continued, however, with gas cut mud accompanied by the inability to control the well.

To amend the drilling events, the operator added an 113⁄4-in. contingency string to the well configuration. Indications were that the cement job around the 113⁄4-in. was poor.

Drilling proceeded with a 105⁄8-in. bit and 121⁄4-in. hole openers to 4,391 m. During attempts to tag the 113⁄4-in. top of liner, the driller realized that the liner was moving downward and was below its top’s reported measured setting depth at 2,916-31 m.

The running of the 97⁄8-95⁄8-in. intermediate casing involved two steps. The first step set a liner, poorly cemented, in the 133⁄8-in. casing and the next step ran a tieback string to surface. The tieback string also had a questionable cement job.

Because of the drilling difficulties, the operator revised the well’s program to complete the well in the Cretaceous instead of its original Jurassic objective.

Drilling of the 81⁄2-in. hole also had gas cut mud, gas shows to surface, mud losses, and uncontrollable flow throughout drilling operation to the final measured depth of 5,195 m.

The drilling fluid used below the 16-in. casing shoe to TD was an inverse emulsion mud.

Inverse emulsion may break down due to contamination and mix with formation fluid, allowing the water phase to come in contact and activate clays.

Supercharging

Some shale or clay formations occasionally have an extraneous seam with some permeability that contains fluids. This seam could have subnormal, normal, or abnormal pressure; however, in most cases the pressure is abnormal because the shale or clays being plastic materials transmit overburden pressure to the fluid contained in the seam,

If a borehole penetrates the seam, a well may kick leading to the increase in mud weight to balance the bottomhole pressure. The higher mud weight might increase the bottomhole circulating pressure higher than the pressure of the fluids in the seam, inducing partial mud losses into the seam.

If safety and trip margin considerations add more mud weight, as per routine practices, annular circulating pressures exerted during circulation may cause the seam to balloon from the partial mud losses.

Under static conditions, no circulation, the seam’s new pressure may be higher than the mud hydrostatic pressure, causing the seam to vent to the wellbore. The venting my increase the mud level in the wellbore, pit gain, that may appear to be a kick.

These kick and partial mud loss cycles as well as routine increases and decreases of lost-circulation material to the mud may cause pressure of the fluid within the seam to reach a supercharged state in which the pressure not only affects the seam matrix and fluid but also affects the surrounding shale or clay.

The formation and seams, in time, may reach a fluidized state and begin to slough and cave into the wellbore, producing a high volume of large cuttings.

The sooner one recognizes the supercharging phenomenon, the sooner one can bring stability to the wellbore and seam.

The breakdown phase, however, requires special and lengthy procedures to unload the hole before resuming normal operations.

Unloading requires circulating of the supercharged wellbore to reduce the amount of suspended cuttings in the mud within the wellbore. This entails long circulation periods during which mud conditioning increases the mud’s carrying capacities for lifting large caved or sloughed cuttings to the surface and simultaneously venting of the extra pressure of the ballooned zone.

The velocity of the cuttings is a function of gravitational forces and mud rheology. Larger particles will reach a depth at which they either float, do not move, or start to fall back downhole.

Cavities create nests where annular velocity decreases. In these areas, mud flow regime changes from turbulent to laminar or plug regime, inducing flow channels. These channels allow cuttings to accumulate in the overgauged hole and nest that may fall downhole as soon as circulation stops, especially when mud properties deteriorate because of contamination.

Caliper logs showed a large cavity at the 16-in. casing shoe and another cavity below 1,990 m. Simultaneous fast drilling in the 105⁄8-in. hole and hole opening to 141⁄2-171⁄2 in. probably created the cavity.

The bottom of the hole at 2,050 m showed a gauged 105⁄8-in. hole that increased upward to more than 25 in. due to bit-hole opener wobble.

Geophysical review

Detailed reviews of different seismic surveys investigated the Bolontiku structures. These reviews showed a disturbed zone straddled by two faults, consisting of crushed rocks and salt diapers from about 1,350 to 1,950 m or about 200 m below the 16-in. casing shoe.

The fault at 1,350 m might have caused cement slurry loss while cementing the 16-in. casing. This interval structurally belongs to a fault that has caused shale movements in the form of a diaper; therefore, the conclusion was that the well was in a highly active tectonic zone that caused the drilling events.

Well completion

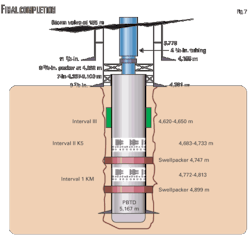

The Bolonitku 43 well reached belatedly its target in the Cretaceous (Fig. 6).

Operations proceeded with the running of a 7-in. slotted liner and four 81⁄4-in. swell-packers. Three of the swell-packers were for isolating three Cretaceous intervals and the fourth was run just above the top of the liner to ensure wellbore integrity.

Due to the 81⁄2-in. hole, 81⁄4-in. swellpackers, the specially drifted 97⁄8-95⁄8-in. casing set at 4,391 m, and the uncommon selection of a 95⁄8-75⁄8 in. liner hanger (OD 8.35-in.), the planned 7-in. liner configuration constituted a stiff liner with very tight annular clearances.

This resulted in the liner failing to reach bottom and its removal. Pulling out the liner from the hole damaged excessively the liner’s accessories. The bottom swell-packers were found prematurely activated.

A modified completion scheme included only two 81⁄4-in. swellpackers with slotted pipe placed at the producing interval.

The well initially produced with a high low-salinity water cut. After a well stimulation job, the well produced with a high 70% low-salinity 40,000 ppm water cut.

Isolation of the slotted pipe and perforating up hole did not improve well performance.

An analysis concluded that the 81⁄2-in. open hole had sustained deep formation damage caused by the inverse emulsion mud. Large quantities of mud were lost to the formation. In addition, longitudinal induced fractures from piston effects caused by tight clearances resulted in casing annuli communication that led to the high low-salinity water cut.

The author