Preventing hydrate formation when wet gas is introduced to a trunkline designed for dry service requires a combination of careful modeling and diligent operation.

The West-East Gas Pipeline runs 4,000 km from Lunnan, Xinjiang, to Shanghai. Three gas sources at Lunnan initially draw from Tarim natural gas field: Kela 2, Yaha, and Sangji.

A May 2005 accident at Kela 2’s gas treatment facilities forced the pipeline to operate under emergency procedures and rapidly reduce the amount of gas transported. Starting June 9, 2005, rough processing gas from Kela 2 entered the trunk pipeline gradually. The trunklines transported a wet gas mixture from Kela 2, Yaha, and Sangji, leading to many operational problems before the low-temperature treatment facility at Kela 2 resumed production in November 2005.

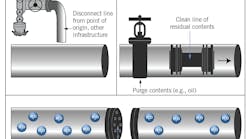

West-East Pipeline (Marketing) Co. pigged the west leg of the trunkline between late May and early June, forcing an ice-like object into a pig receiver (Fig. 1). The flammable nature of the object (Fig. 2) confirmed hydrate formation in the pipeline.

West-East Pipeline (Marketing) hired China University of Petroleum (CUP) to conduct experiments and research on hydrate-forming conditions of the source gas to ensure the pipeline, designed to deliver dry gas, could still operate normally. This article discusses the results of these experiments and research.

Sampling gas

Seven gas samples taken from different sites defined the pipeline’s gas composition. Four samples came from Tarim field, Lunnan station, and three were taken along the West-East Gas Pipeline trunk. These included:

- Sangji field at Lunnan station(S1).

- Yaha field, Kela 2 at Lunnan station (S2).

- Yaha field at Valve Room 4 (S3).

- Kela 2 field at Valve Room 4 (S4).

- Gulang pigging station (S5).

- Valve Room 53 at Jinchang (S6).

- Shandan compressor station (S7).

The last three of these came from the trunk line. An HP6890 chromatograph at CUP determined gas sample composition. Table 1 lists the results.

Hydrate formation

Water and small gas molecules such as CH4, C2H6, C3H8, CO2, H2S, N2, and SO2 form natural gas hydrates; crystals with the appearance of snow or ice powder. Hydrate formation needs proper gas composition and thermal conditions: a certain quantity of water and small gas molecules, and the appropriate temperature and pressure.

Hydrates form more easily when temperature is lower and pressure higher. A sapphire autoclave determined hydrate formation conditions of the gas samples (Fig. 3). The autoclave’s maximum effective volume measured 60 cc, with a maximum operating pressure of 20 MPa and operating temperature ranging between –90° C. and 150° C.

The common experimental method to determine hydrate forming conditions in the laboratory is the pressure-search method, which changes system pressure at a constant temperature to determine equilibrium conditions. System temperature and pressure remaining constant for >4-6 hr with a small amount of hydrate particles remaining in the system define temperature and pressure as at equilibrium. This method determined hydrate forming conditions for all gas samples.

Pressure ranged between 2.80 and 7.1 MPa and temperature between 276.15 and 288.15 K. Table 2 lists the experimental results.

The gas samples taken along the trunk line have similar composition, so that only the forming condition at S5 was measured. Since gas transported in the West-East Gas Pipeline mixed the three gas sources in different ratios, gas composition varied. The predicting model developed in this article can measure varied gas compositions.

Most existing thermodynamic models for predicting hydrate formation modify the vdWP model proposed by van der Waals and Platteeuw. These models, however, have a relatively large deviation. The Chen-Guo model, based on statistical mechanics and a two-step hydrate formation mechanism, has a clearer physical meaning, simpler mathematical expression, and more accurate results.1 2

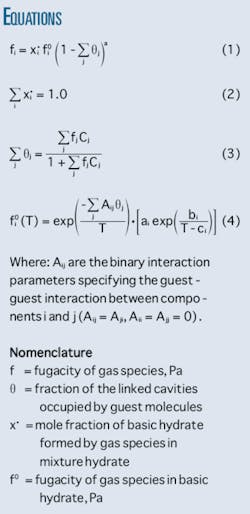

Equations 1-3 express the Chen-Guo model. Taking the interactions between guest molecules in linked cavities and basic cavities into account yields Equation 4.

This article used the PR-Equation of State,3 before achieving gas-liquid-liquid-hydrate flash equilibrium and determining hydrate forming conditions.

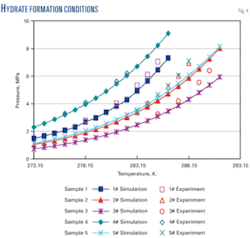

A comparison between simulation results and experimental data verified the model. Fig. 4 shows the simulation results in good agreement with the experimental results, verifying the models usability in predicting hydrate-formation conditions on the West-East Gas Pipeline.

Fig. 4 shows hydrate-forming temperature of 283.15-293.15 K. when the pipeline operates between 7 and 10 MPa. Once free water exists in a pipeline hydrates may be formed, requiring its exclusion regardless of operating conditions. The temperature of gas in the pipeline equals the temperature of soil in situ (Table 3).

Hydrate prevention

Hydrate formation requires free water in the pipeline. All the water in wet gas sourced from Kela 2 field will not enter the West-East Gas Pipeline, as some will deposit in the 138-km branch line from Kela 2 to Lunnan before it joins the other two gas sources. The water content in the trunkline therefore is the average of those of three gas sources, with precipitation of Kela 2 wet gas in the branch line taken into account and decreasing the water content.

Controlling and adjusting the ratios of gas from the three sources during different months ensured secure operation (no hydrate formation) under these conditions.

From June to August gas from Yaha field measured 3.5 × 106 cu m/day, gas from Sangji field 3 × 106 cu m/day, and gas from Kela 2 field 4 × 106 cu m/day. Small amounts of water precipitated with these ratios, but no hydrates formed because the temperature of soil was higher than the forming temperature. In September and October volumes from Kela 2 field dropped to 3 × 106 cu m/day to lower the water content, and remaining gas containing more saturated water was forced to the east section from the west section to prevent water precipitation.

Wet gas supplies from Kela 2 stopped in November, with the newly returned dry gas gradually displacing the wet gas from west to east, ensuring free water did not precipitate and completing successful operation of the pipeline through the accident period.

References

- Chen, G.J., and Guo, T.M., “A New Approach to Gas Hydrate Modeling,” Chemical. Engineering Journal, No. 71, pp. 145-151, 1998.

- Chen, G.J., and Guo, T.M., “Thermodynamic Modeling of Hydrate Formation Based on New Concepts,” Fluid Phase Equilibria, No. 112, pp. 43-65, 1996.

- Peng, D.Y., and Robinson, D.B., “A new Two-Constant Equation of State,” Industrial and Engineering Chemical Fundamentals, No. 15, pp. 59-64, 1976.

The authors

Jian-Kui Zhao ([email protected]) is a PhD candidate at Beijing Key Laboratory of Urban Oil and Gas Distribution Technology, Department of Oil & Gas Storage and Transportation, China University of Petroleum.

Jing Gong ([email protected]) is a professor at China University of Petroleum. She also serves as deputy dean of petroleum engineering at the university, concentrating on transportation technology of long-distance pipelines and theory and technology of multiphase flow and oil-gas gathering. She earned her PhD in oil and gas storage and transportation from China University of Petroleum-Beijing in 1995.

Qing-Chun Xia ([email protected]) is an engineer in the department of program and planning for the West-East Pipeline (Marketing) Co. He holds an MS from the China University of Petroleum-Beijing.