Project undertakes deepwater production measurement gaps

A new joint interest research project aims to improve production measurements from deepwater fields.

The Letton-Hall Group, Houston, received a contract from the nonprofit Research Partnership to Secure Energy for America (RPSEA) for the project.

“This project is significant because, if successful, it will clear the way to more affordable, more realistic deepwater production,” says Jim Chitwood with RPSEA.

“The current situation in deepwater exploration is that often companies may drill several deepwater wells and commingle their production. Measuring the flow from each well and allocating the oil and gas production is a big issue at those depths,” he says.

Jim Hall, cofounder in the Letton-Hall Group, told OGJ that the project came into effect on Nov. 1, 2008, with work starting in February 2009.

REPSA will provide 80% of the $4.5 million budget with the other funding coming from seven initial companies: BHP Billiton Ltd., BP PLC, Chevron Corp., ConocoPhillips, Royal Dutch Shell Group, StatoilHydro, and Total SA. Each company’s contribution to the project is $150,000, meaning that the project is currently overfunded by $150,000, Hall said. He also thought some additional companies might also join the project.

The six tasks the project will look at are:

- Deepwater subsea sampling.

- Remotely operated vehicle (ROV) assisted subsea flow measurement.

- High pressure, high-temperature qualification of flow measurements.

- Flow modeling evaluation.

- Meter fouling.

- Metering system uncertainty.

Hall said the deepwater subsea sampling part of the project will last 2½ years, while the other parts are scheduled for completion in 2 years.

The project has signed contracts for the ROV part of the work with Oceaneering International Inc., Houston, and with Multiphase Systems Engineering at the University of Tulsa for evaluating models and metering systems.

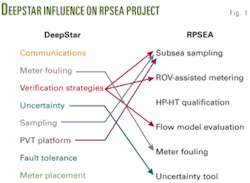

Hall noted that DeepStar Project 8302 for improved multiphase metering for subsea tiebacks had identified many of the tasks slated in RPSEA Project DW1301 for improving deepwater measurements. Fig. 1 shows the relationship between the DeepStar and RPSEA projects.

RPSEA’s funding comes from the US Energy Policy Act of 2005 that funds natural gas supply research and development programs during 10 years. RPSEA is the consortium selected to manage these funds.

Deepwater subsea sampling

Although the placement of subsea multiphase flowmeters near the well improves reservoir management, well diagnostics, and allocation, the project’s scope notes that multiphase flowmeters require timely, accurate fluid properties, at meter conditions and that well tests and topside samples cannot meet these needs.

The scope says that sampling at or near the wellhead can provide samples that represent the fluid flowing through the meter, yielding more accurate fluid properties and more accurate multiphase measurements than the current costly and inaccurate methods for determining gas properties via topside samples.

Its plan to develop a method for ROV-deployed subsea sampling will provide a means to capture representative fluid samples at the multiphase meter and other locations at various times throughout the life of the well.

The proposed work will develop a standardized, ROV-deployed sampling system that gathers subsea samples in situ, near the well, resulting in more timely and accurate fluid properties for improved allocation, well monitoring and diagnostics, and reservoir management.

This sampling part of the project will evaluate the potential of existing sample systems and conceptual designs deployed via ROV. The work also includes selection, development, and testing of a candidate system with an ROV, as well as development of draft standards for sampling connections (interfaces), tools, equipment, and operations.

ROV assisted measurement

The project’s scope notes that verification of deepwater subsea flowmeters is key to removing risk from both the allocation of revenue among producers and the collection of royalties in US federal waters. It says while the meters may measure multiphase flow from wells when they are first installed, this becomes an increasingly difficult task as fields and equipment age. This drift away from correct operation will lead to incorrect fiscal allocation of revenues and assessment of royalties.

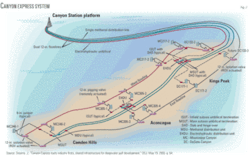

Hall noted that the Canyon Express development in the Gulf of Mexico was an example of the need for this technology. Canyon Express involved production from eight wells in three fields with several owners and differing royalty rates commingled in two flowlines. Each well initially produced gas with small amounts of condensate and, in a few cases, water. The production balance from the two flowlines with topside separator measurements was about 6-8%, but this deteriorated to 15-25% within a few months.1

At that point, total production from all wells averaged about 450 MMscfd, so that a 20% imbalance represented 90 MMscfd, or more than $250,000/day at the prevailing 2003 prices of 2003.1 Fig. 2 shows the fields in 2003 (OGJ, May 19, 2003, p. 64).

The project’s scope for this second task is for developing methods to convey measurement equipment to the wellsite where it will be clamped on at a predefined position. It expects that production allocations will improve by making and comparing measurements from each well contributing to the commingled production.

Hall said that the project currently is not focusing on any technology. He said that a gamma-ray densitometer is a leading candidate because ultrasonic meters currently cannot go underwater.

HP-HT qualification

The project’s scope notes that current subsea multiphase and wet-gas flowmeters have a 125° C. temperature and 10,000-psi operating pressure limit. To increase measurement capability to 15,000 psi, Task 3 aims to address these operational restrictions by identifying the sources of the limitations in the most universally used sensors in multiphase and wet-gas flowmeters.

These sensors include those for measuring pressure, temperature, and differential pressure.

The project will assemble and, if required, design and fabricate prototype sensors and then integrate the sensor elements into transmitter housings designed to meet an operational pressure of at least 15,000 psi.

The scope notes that because of the cost required to develop sensors for these applications and the small yearly sales potential of probably fewer than 1,000, a sensor manufacturer would be unlikely to undertake this development without external funding.

Evaluation of flow modeling

The scope notes flow modeling, commercially called virtual flowmeter (VFM) technology, is maturing, but the industry has only a few studies that evaluate the performance and accuracy of commercially available VFM’s for subsea systems.

Task 4 will address this gap in studies of current VFM technology. The project plans to evaluate existing VFM by comparing the predictions of the VFM’s with actual field data from subsea multiphase flowmeters or other measurement sources.

Its objective is to identify areas of strengths and weaknesses. By documenting where existing VFM’s can function within the required error limits, it will establish boundaries on their use. By categorizing the operating regions where existing VFM’s need enhancements, this task will provide guidance to future needed developments to extend the operating envelope.

This task will provide the industry with applicable operating conditions for VFMs, enabling more confidence in their use.

Another benefit for the work is probable regulatory authority acceptance of the use of VFM systems, both for verification method of fiscal allocation and as a backup to physical subsea flowmeters.

Meter fouling effects

Field operations show that meters can become fouled or altered by scale, wax, asphaltenes, hydrates, corrosion, and erosion. Task 5 will evaluate these effects on measurement and determine their nature and magnitude.

The project will address gaps in the deployment and use of multiphase and wet-gas metering technology in deepwater production systems, as well as provide insights into ways fouling can alter meter response.

The scope of the tests will evaluate commonly used multiphase meter elements, such as the Venturi and cone, to determine the effect on meter of synthetic deposition such as scale and wax or erosion.

Canyon Express is an example of the importance of fouling because one conclusion from that project was that the presence of scale on the walls of some meters caused incorrect response of the meters, essentially changing their discharge coefficient.1

Metering system uncertainty

Task 6 will analyze flow rate measurement uncertainty, which is a key methodology for addressing production allocation, reservoir performance optimization, operational issues, and regulatory reasons.

The scope notes that the industry has no unique procedures for predicting total system uncertainty associated with multiphase flowmeters, well test separator systems, and the pipelines connecting them, especially for commingled flow configurations.

The project will investigate and quantify the uncertainty, both bias and random, associated with meters in two or three-phase flow. In addition, it will determine detailed characterization of multiphase pipeline flow that will involve both the propagation of uncertainty in pressure-volume-temperature (PVT) models to local flow conditions, as well as uncertainties that result from the transient nature of the multiphase flow in the pipe.

Another part of the project will extend the previously developed well test measurement uncertainty analysis to multiphase meters. It will base the extension on the physical principle of the meter and the associated hydrodynamic flow behavior.

From this work, it plans to deliver a software tool with a user friendly interface for predicting total network uncertainties for systems with subsea multiphase flowmeters, accounting for meter operating conditions, in situ PVT properties, system configurations (such as commingled flow), and pipeline uncertainties.

It notes that knowledge of system-wide uncertainty will facilitate verification of meter performance and fair allocation of produced fluids, provide early indication of measurement problems anywhere in the system, and provide all parties (vendors, operators, partners, service companies, and regulatory agencies) a realistic picture of the measurement quality.

Reference

- Hall, J., et al., “Deepwater Measurement Verification—a DeepStar-RPSEA Mandate,” 26th International North Sea Flow Measurement Workshop, Aberdeen, Oct. 21-24, 2008.