CBM reservoir thickness affects production from horizontal wells

A stimulation study shows the importance of considering reservoir thickness when developing low–permeability coalbed methane resources with a horizontal lateral.

The study determined that when the thickness is less than a critical value, the well will produce less cumulative gas and decrease its commercial value. When the thickness exceeds the critical thickness, the productivity will not increase as reservoir thickness increases but will remain stable as thickness increases.

In addition, initial gas production from a horizontal well in a low–permeable coalbed methane reservoir will decrease in thick reservoirs. The peak gas rate will be less at first and than increase later as reservoir thickness increases.

Simulation basis

The authors have based the equations proposed for this simulation study on the Langmuir equation, Fick’s pseudosteady–state law, and Darcy’s equation. The study combines the equivalent radius model and function of pseudopressure to take into effect diffusivity and compressibility.

To solve the equations, the study uses a finite difference method, after which it establishes partial differential equations and definite conditions that describe the mechanism of coal gas and water flow.

Objectives

At present, most coalbed methane reservoir developments in China use fractured vertical wells and herringbone horizontal wells.

The cost of a fractured vertical well is low but these wells have a limited drainage area. The drainage area of herringbone horizontal wells is greater in comparison, but the wells have an initial higher cost.

Although common for developing hydrocarbon reservoirs, horizontal wells are much less common for CBM reservoirs.

The CBM reservoirs in China always have a low permeability, less than 1 md,1 and the reservoir pressure always is less than in other countries.2 These factors are general characters in China, but the coalbed thickness varies substantially.

The study describes mathematical models for CBM and water flow by taking into account desorption, diffusion, and filtration. It also is the first study to incorporate gas compressibility.

The objectives of the study were to:

- Develop a method of analyzing horizontal well productivity by considering the property of diffusivity and compressibility for CBM.

- Validate the existence of critical reservoir thickness in developing low–permeable CBM reservoirs with horizontal wells.

- Provide a theoretical range of critical reservoir thickness.

Gas, water flow model

The characteristics of coalbeds in China are the basis for the study’s geologic model. To develop the transport equations for the water and gas phases, the study uses assumptions such as:

- The coalbed is a double–porosity medium composed of matrix and fractures.

- The coalbed is compressible, heterogenic, and anisotropic.

- Water initially saturates the fractures with no free gas or dissolved gas within. Gas is adsorbed in the matrix pores that contain no water.

- Gas flow in fractures includes diffusivity and compressibility, in which diffusion is in the pseudosteady–state regime.

- The study considers the effects of gravity and capillary pressure.

- Flow is isothermal.

- Methane is a real gas. Water is a slightly compressible fluid.

- The gas on the matrix face is in equilibrium with the free gas in fractures.

Mathematical model

Three steps describe the flow of methane in the reservoir: desorption, diffusion, and filtration.3 As a result of the specific property of storage and transport, the study incorporates synthetically the model of adsorption–desorption, the model of matrix diffusion, and the model of Darcy filtration.

This study also incorporates gas and water flow in the matrix, fractures, and well. The Langmuir equation characterizes the gas adsorbing concentration in the micropores of the coal matrix and the exchange capacity between adsorbed gas on the matrix face and free gas in the fractures.4

The gas flow velocity in fractures consists of the diffusion velocity and Darcy velocity. The pseudosteady–state diffusion equation reflects the character of diffusion.5 Recent mathematical models have ignored the compressibility influence. As a result, the deliverability equation for a gas well is not different from the equation for liquid, which is inconsistent with the actual conditions.

We have derived a real–gas deliverability equation for radial fluid flow by taking into account a pseudopressure function6 and equivalent radius model. The accompanying equation box shows the models.

Numerical solution

Equation 8 has four unknowns: pg, pw, Sg, and Sw. Only two are independent variables and one can express the others as functions of the independent ones. We selected gas pressure pg and water saturation Sw as the independent variables.

To solve the equations easily, we solved for the real parameters in the iterative step k+1 not with pgk+1 and Swk+1 but with the increment δpg and δSw. One should pay attention to the grids that locate the well because one must transform the pressure into real–gas pseudopressure to calculate productivity.

In addition, one can evaluate the productivity by introducing an equivalent radius model if the reservoir along the horizontal well is heterogeneous.

We treat the components on the left of the partial differential equations for gas and water as dimensional difference with block–centered grid and treat the components on the right as time difference.

After the set of difference equations describing the gas and water flow through coalbed is established, we treat the Darcy term, desorption term, diffusion term, and well productivity term implicitly. Then we obtain the nonlinear fully implicit model of gas and water flow through coalbed with Equations 9–11.

We adopted the Newton–Raphson algorithm to linearize the nonlinear equations. The matrix of coefficients is a seven diagonal, blocky, and banded sparse. Each block is a submatrix of two series. We can transform the equations into seven diagonals after we set initial bottomhole pressure. Then we can solve the model with an orthomin algorithm.

We can write the nonlinear equations in matrix form (Equation 12).

Thickness analysis

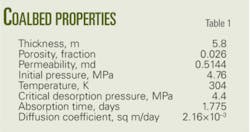

Table 1 summarizes the physical properties of the coals used in the study. The parameters are from No. 3 coalbed Jinshi 1 well in Fanzhuang block of the Qinshui basin.

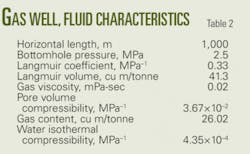

Table 2 summarizes the gas well and fluid characteristics. The study changed the coalbed thickness to determine its influence on gas production.

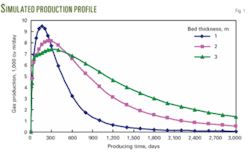

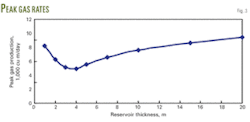

Fig. 1 indicates that peak production rate decreases as thickness increases; however, thicker reservoirs have longer flow periods. Production from the 3–m thick coalbed would still be 1,365 cu m/day after 3,000 days, while production from the 1–m thick bed would be less than 1,000 cu m/day after 1,000 days.

As expected with thinner coals, the reservoir will dewater more effectively, thereby lowering fracture pressure sooner. This results in a higher initial gas production as well as the peak gas production rate occurring sooner than in a thicker coalbed. The deep drop in reservoir pressure, however, will cause the thinner bed to suffer more from the crustal stress that lowers the permeability, and therefore the production rate will decline quickly after the peak gas rate.

In thicker reservoirs it is different because the effect of matrix shrinkage will dominate as the pressure drops, thereby enhancing the permeability.8 As a result, the production rate will stay higher after the peak gas rate.

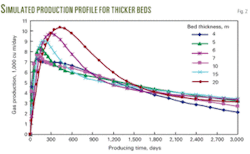

Fig. 2 shows simulated production profiles for reservoir thicknesses greater than 4 m. The figure indicates that as reservoir thickness increases, the peak gas rate increases, the time of peak gas rate is delayed, and the production period lengthens.

The production difference of the two thicknesses, however, becomes nearly the same as the well continues to produce after the peak. The thinner coal beds have less of a difference.

Fig. 3 illustrates that peak gas rates will decrease as thickness increases to 4 m and than start increasing. Peak gas production rate is at minimum, about 7,300 cu m/day, when the thickness is 3–4 m.

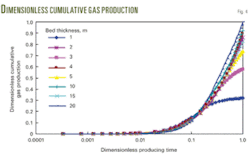

To determine the reason for this phenomenon and to verify the existence of a critical reservoir thickness, we looked at the relationship between dimensional cumulative gas production and dimensional time (Fig. 4).

Fig. 4 indicates that as thickness increases, the different in dimensional cumulative gas production between two thicknesses is less. When the reservoir thickness is greater than 4 m, the difference is negligible. Only when the thickness is greater than 15 m, the well will have a slight increase in cumulative gas production, indicating that a horizontal well does not have much of an advantage in thicker coalbeds.

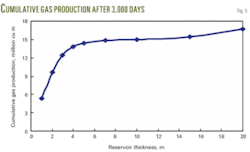

This conclusion is also illustrated in Fig. 5 that plots cumulative gas production after 3,000 days for different thicknesses. In the figure, the cumulative gas production is much more stable when the thickness is greater than 4 m. The reservoir thickness does not affect the long–term productivity. Thus, we can conclude that the benefit of a horizontal well is less in thick coalbeds.

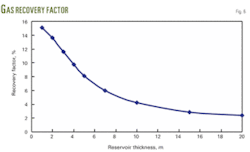

Fig. 6 shows gas recoveries for different thicknesses. We can draw the conclusion that thinner coal beds have a higher recovery factor. The cumulative gas production, however, is lower because of the size of the reserves are less.

As the reservoir thickness increases, the recovery factor is lower because the gas will not desorb as efficiently as in thinner beds, but the cumulative gas produced is higher.

As illustrated in Fig. 6, although the recovery factor keeps decreasing as the thickness increases, the change in recovery decrease is less when the thickness is comparatively thick.

Acknowledgment

The authors thank State Key Research Project “Well completion, high efficient stimulation and equipment development for coalbed methane” (2008ZX05000–037) for supporting this research.

References

- Song, Yan, et al., Reservoir Mechanism and Theoretical Base of Economic Development for Coalbed Methane, Beijing: Science Press, 2005.

- Zhao Qingbo, et al., “Geology and Exploratory Development Technique for Coalbed Methane,” Beijing: Petroleum Industry Press, 1999.

- Gray, I., “Reservoir Engineering in Coal Seams: Part 1—The Physical Process of Gas Storage and Movement in Coal Seams,” SPE Reservoir Engineering, Vol. 2, No. 1, February 1987, pp. 28–34.

- Langmuir, I., “The Constitution and Fundamental Properties of Solids and Liquids,” Journal of the American Chemical Society, Vol. 38, No. 11, 1916, pp. 2221–295.

- Jin, Zhengguo, et al., Base of Materials Science, Beijing: Tianjin University Press, 2005.

- Al–Hussainy, R., et al., “The Flow of Real Gases Through Porous Media,” JPT, May 1966, 624–36.

- Yu, Guodong, The Art of Productivity for Horizontal Wells, Beijing: China University of Geosciences, 2006.

- Zhang, Jian, and Wang Zhiming, “Effects of Coal Bed Stress on Fracture Permeability,” Journal of China University of Petroleum, Vol. 32, No. 6, 2008, pp. 92–95.

The authors

Wang Zhiming ([email protected]) is a professor in the petroleum engineering department at China University of Petroleum, Beijing. His main research interests are in dynamics of complex fluids and well completion engineering. Wang holds a PhD from China University of Petroleum. He is a member of SPE.

Zhang Jian (zhangjian_ [email protected]) is a PhD student at the MOE Key Laboratory of Petroleum Engineering at China University of Petroleum, Beijing. His current research interests include CBM exploitation and well completion engineering.