EXTERNAL CORROSION— Conclusion: Cased pipe segments could be less safe than uncased segments

A comparison of scheduled or immediate responses/mile vs. number of repairs from an Interstate Natural Gas Association of America (INGAA) study and the US Pipeline and Hazardous Materials Safety Administration (PHMSA) database suggests cased pipe segments could be less safe than uncased segments, although this result is not conclusive.

New analysis of US Office of Pipeline Safety (OPS) 1988 report data and analysis of new data provided for this study, however, show that shorted casings are more susceptible to corrosion than nonshorted casings. This result contradicts the OPS conclusion in 1988: “A shorted casing does not enhance or reduce corrosion activity on carrier pipe.” The OPS study neglected the fact that the nonshorted casings were much more numerous than shorted casings.

Depression of cathodic protection (CP) current resulting in elevated corrosion of the carrier pipe upstream and downstream of the casing ends can occur when a metallic short or electrolytic coupling exists between the casing and the carrier pipe. Nonconductive filler in the casing-carrier pipe annulus may not fully eliminate external corrosion of the carrier pipe in the casing unless a high quality filler is properly applied and does not deteriorate.

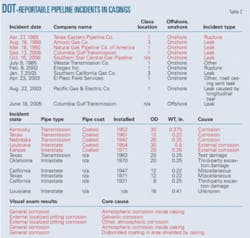

A review of reportable pipeline incidents in casings between Aug. 7, 1984, and Nov. 8, 2006, in the OPS-record database shows among 11 incidents identified, 5 were known to be caused by corrosion, 3 by excavation, and 3 by unknown causes. Of the 5 corrosion incidents, 3 resulted from atmospheric corrosion.

Although peak anomalies tend to be located near the ends of the casing (see Part 1, OGJ, Apr. 6, 2009, p. 56), the severity of the individual anomalies determined by the factor of safety does not depend on location.

Part 1 of this article reviewed the background of this issue and described the data gathering and analysis methods used in reassessing casings’ role in corrosion.

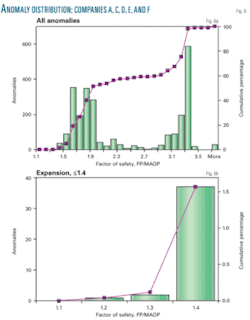

Anomaly distribution

The factor of safety (FP/MAOP) reflects the severity of damage to cased pipe integrity by corrosion anomalies independent of an individual pipe’s nominal WT, OD, and steel properties characterized by the specified minimum yield strength (SMYS) because both failure pressure (FP) and maximum allowable operating pressure (MAOP) are proportional to the term SMYS (2 × WT/OD), based on the original or modified ASME B31G. FP/MAOP thus can give an unbiased estimate of the threat of corrosion anomalies for different pipe sections (with different WT or OD) from different operators.

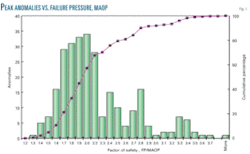

Fig. 1 shows a plot of the number and cumulative percentage of anomalies vs. FP/MAOP. Only five peak anomalies of the total 272 have FP/MAOP less than 1.39 (requiring a scheduled response action following Modified B31G). These do not, however, include the deepest anomaly (84% WT) whose FP/MAOP is rather large, 1.64, due to its small length (0.79 in.).

Following modified ASME B31G criteria, the pipe segment containing this deepest anomaly (>80% WT) requires replacement to prevent a leak. The lowest FP/MAOP for all peak anomalies is 1.28.

Excluding this deepest anomaly, 98.2% of the remaining peak anomalies require no response action according to modified B31G for carrier pipes with a design factor of 0.72. For crossings of roads or railroads with casings, ASME B31.8 recommends a design factor of 0.72 (1/1.39) for both Division 1 and Division 2 of Class 1, except for private roads of Division 1 where the recommended design factor is 0.8.

Of all cased pipe segments studied for this article, 2,733 in total, 99.82% do not require response action

Fig. 1 also shows 46% of all anomalies as having FP/MAOP falling between 1.7 and 2.1, inclusive. The average is 2.1 and the median is 2.0. This high average ratio reinforces the idea that cased crossings are in excellent condition overall.

FP/MAOP can help determine if the severity of an individual anomaly is preferentially located near the ends of cased pipe segments, similar to the preferential location of anomalies along cased pipe segments discussed in Part 1.

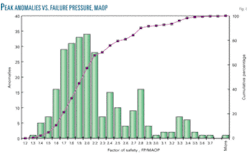

Fig. 2 shows the distribution of anomalies vs. FP/MAOP, calculated with the number of anomalies in every 0.1 interval of FP/MAOP divided by the subtotal number of the anomalies within an interest range of shortest distance from the ends of cased pipe segments (0-5 ft, 5-10 ft, 10-20 ft, 20-50 ft, and more than 50 ft). The number of anomalies within these five ranges is similar.

Fig. 2a shows the percent distribution of anomalies vs. FP/MAOP for each range, with a point to replace column bars such as shown in Fig. 1. Fig. 2b represents the cumulative distribution of anomalies vs. FP/MAOP; the integration of Fig. 2a normalized to 100%.

The patterns for the five different distance ranges are similar in each figure. Since the difference in the distribution for the five different distance ranges reflects levels of the corrosion damage severity along cased pipe segments, the similarity of the five distributions (representing different distances along the cased pipe segments) indicates the damage severity of individual anomalies does not depend on locations.

A simple example is given here to explain the nonpreferential location of damage severity of peak anomalies represented by FP/MAOP. For multiple casings on one pipeline with the same carrier, OD, WT, and operating conditions, this nonpreferential distribution of FP/MAOP means peak anomalies have similar sizes (depth and length) regardless of being near the ends of casings or between the ends.

Report review

The 1988 OPS report2 under the US Department of Transportation stated, based on a casing study, that “a shorted casing does not enhance or reduce corrosion activity on carrier pipe.” This statement seems to contradict the normal understanding that a metallic short can increase the chances of carrier pipe corrosion because of its possible elimination of CP benefits.

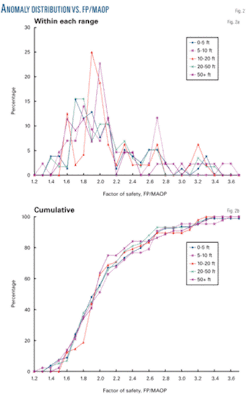

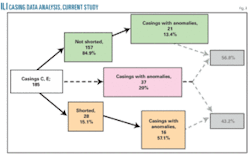

Fig. 3 summarizes the ILI data for cased pipe segments in this OPS report following reexamination and new analysis in the current study. Among the total 1,043 casings, the nonshorted casings (a subtotal of 862 casings or 83% of total casings) are four times more numerous than the shorted casings (a subtotal of 181 casings or 17% of total casings).

Although the number of cased pipe segments with corrosion anomalies (anomaly depth was not specified in the report) for nonshorted casings (21) is slightly less than for shorted casings (23), the percentage of nonshorted cased pipe segments with anomalies among its subtotal (2.4%, or 21 of 862) is much smaller than the percentage of shorted casings (12.7%, 23 of 181), suggesting shorted casings are more susceptible to corrosion than nonshorted casings.

The 1988 OPS report2 compared only the percentage of the 21 nonshorted vs. the 23 shorted cased pipe segments with anomalies (44 total casings). Anomalies were found on 47.7 % of the nonshorted cased pipe segments and 53.3 % of shorted cased pipe segments. This comparison, however, neglected the fact that nonshorted cased pipe segments included were four times more prevalent in the data set than the shorted cased pipe segments, which should be taken into account when comparing the susceptibility of the shorted or nonshorted casings to external corrosion.

The higher susceptibility of shorted cased pipe segments to corrosion suggests metallic shorts increase the chance of external pipe corrosion and thus shorted casings should be given higher priority when conducting integrity assessment.

Results

Only four companies provided data for this study with shorted and nonshorted casings labeled. But data from only two of these four companies included corrosion peak anomalies of any depth, information sufficient to determine the effect of metallic short on external corrosion.

Table 1 summarizes data from these two companies, for which both total casings, including those without anomalies on the carrier pipe, and casings with a peak anomaly depth of 20% WT or greater on the carrier pipe are included for both shorted and nonshorted casings.

Fig. 4 graphically presents the numerical values of Table 1, offering a comparison with Fig. 3. Consistent with Fig. 3, Fig. 4 shows nonshorted casings (a subtotal of 157) are four times more prevalent than shorted casings (28), even though the number of casings with a peak anomaly depth of 20% or greater is similar regardless of the casings being shorted or nonshorted. This result reinforces the supposition that metallic shorts can increase the corrosion susceptibility of carrier pipe in casings.

As discussed in Part 1, the carrier pipe in casing can be protected by CP when it is partially or fully submerged in electrolyte in the annulus and when the casing and carrier pipe are isolated. When the casing wall is bare, this large bare surface with a more positive potential than the carrier pipe can serve as a conductor drawing CP current otherwise flowing to the carrier pipe outside the casing. This can result in CP current depression or reduced CP protection on the carrier pipe upstream and downstream near the casing ends. This CP current depression would increase when there is presence of short, which further minimizes resistance of CP current flow to the carrier pipe inside the casing, allowing more current to be from soils upstream and downstream of the casing ends.

Data were not available in this study to provide a quantitative understanding of the performance of a nonconductive electrolyte filler, but several points concerning this matter bear discussion. Some believe placing a nonconductive material in the annulus eliminates all corrosion problems, based on the theory that the nonconductive material can block the electrolyte pathway required for corrosion to occur. In reality, the wellness and durability of the filling can depend on the type and quality of nonconductive material used and how it is placed.

Poor field application or low quality filler could lead to conditions in which the annular spaces are not full, cracks develop in the filling, or gaps are left between the filling and casing-pipe wall. Degradation of the material over time and CP shielding of an electrolyte path, if it develops within cracks, can induce corrosion which might be avoided if the filling were absent.

Field incidents

A review of reportable natural gas pipeline incidents involving casings in the OPS database includes two incidents useful in gaining an understanding of real corrosion incidents involving casings.2

• Colonial Pipeline Co. (1980, hazardous liquid pipeline). An incident occurred on Mar. 6, 1980, on a Colonial Pipeline 32-in. OD liquid pipeline inside a cased highway road crossing in Virginia. The failure resulted in an estimated loss of 8,000 bbl of aviation kerosine. No human deaths or injuries occurred, but 5,000 fish and small animals lost their lives because of the failure. Cleanup of the polluted farm land, streams, river banks, and reservoirs took several months.

The casing had been electrically shorted to the carrier pipe for 10-12 years. Metallurgical examination of the failure led to the following conclusion: The “failure occurred at an area near the bottom of the pipe that had been thinned by corrosion. Apparently, the corrosion resulted from ground water leakage past the pipe-to-casing seal and into the annular space between the pipe and casing, where shielding effect of the casing would mitigate against obtaining adequate CP in this area….”

The report also stated: “The fact that the casing was shorted to the pipe may have prevented a small amount of CP current from entering the annular space, but the effect on the overall rate of attack probably was small.”

This OPS report regarded the metallic short as a minor factor in the incident, while the shielding effect was treated as the major cause. It is, however, likely the shielding effect resulted mainly from the short, and the short therefore is likely a key factor in the incident. Experimental tests showed sufficient CP can be achieved on the carrier pipe if the casing-pipe annulus is filled with electrolyte and the casing and pipe isolated.3-5 Direct metallic short could remove the CP benefit and allow free corrosion to occur.

• Texas Eastern Gas Pipeline Co. (1985, natural gas pipeline). The National Transportation Safety Board (NTSB) report of Feb. 18, 1987, detailed an incident on Apr. 27, 1985, when a 30-in. OD natural gas pipeline owned by Texas Eastern ruptured under Kentucky State Highway 90.

The escaping gas ignited and burned an area about 700 ft long and 500 ft wide. Five persons in one house were killed and three others burned as they ran from their mobile home. There was extensive damage to buildings, construction equipment, and other property.

The NTSB report stated the probable cause of the accident was “unsuspected and undetected atmospheric corrosion.” Atmospheric corrosion occurs on a pipeline when moisture from the air, along with contaminates, comes into contact with the exposed metal.6

This casing was located about 2 miles downstream of a compressor station with line temperatures of 140-160° F. High heat had badly damaged the coating. The presence of vents and the line temperatures consistently higher than local temperature caused cyclic water condensation on the carrier pipe, providing electrolyte necessary for the atmospheric corrosion.

Reviewing the DOT reportable incident database for the period between Aug. 7, 1984, and Nov. 8, 2006, provided an understanding of the number of incidents involving cased crossings and the number caused by external corrosion.

A search of the DOT reportable-incident database related to casings turned up a total of 11 incidents involving cased crossings. Table 2 summarizes these incidents.

Among the 11 known incidents, corrosion caused 5 (highlighted in red on the table). Excavation damage accounted for 3. Reports noted the causes of the other 3 incidents as either unknown or miscellaneous. These results point to corrosion and excavation as the primary causes of failures in cased crossings.

Of the 5 corrosion incidents, 3 resulted from atmospheric corrosion (Texas Eastern Pipeline Co., 1985; Natural Gas Pipeline Co. of America, 1992; and Columbia Gulf Transmission, 2006).

A more recent incident took place on a Columbia Gulf Transmission Co. gas line Dec. 14, 2007, near Delhi, La.7 A natural gas release, explosion, and fire killed one person and injured another in the same vehicle as they traveled on the highway where the pipe crosses in a casing.

Investigators do not know the exact cause of the failure, but a preliminary visual examination suggested external corrosion to be the cause. Investigators suspect corrosion inside the casing caused the explosion, but are not certain whether the failure actually initiated inside or outside the casing.

Relative safety

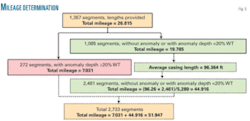

The casing length distribution determines total mileage of the 2,733 casings surveyed for this study (Fig. 5). Actual casing data determined the values in the blocks with solid edges; values in blocks with broken edges were calculated.

Of the 2,733 casings, known lengths existed for 1,357 with a total mileage of 26.815. This mileage consists of 7.031 miles of 272 casings containing a peak anomaly =20% WT and 19.785 miles of the remaining 1,085 casings that either do not have an anomaly or have a peak anomaly depth <20% WT. The average length of the latter casings is 96.36 ft.

This average can be used to derive the mileage of the 2,461 (2,733 minus 272) casings that either do not have an anomaly or have a peak anomaly depth <20% WT. The mileage of these 2,461 casings equals 44.916. Adding this to mileage of the 272 casings with peak anomaly depth = 20% WT yields a total mileage for 2,733 casings of 51.947.

Of the estimated 51.947 miles of casings surveyed, 5 peak anomalies have FP/MAOP <1.39. These anomalies do not include the anomaly with depth of 84% WT. Using 5 as the number for scheduled responses yields a response rate of 0.0963 scheduled response/mile.

Since no anomaly has an FP/MAOP <1.1, no immediate response is required. The anomaly of 84% WT in depth requires replacement of the pipe section, a rate of 0.019 replacement/mile. Including this deepest anomaly in the scheduled response yields a scheduled response and replacement response/mile of 0.115.

The exclusion of one casing with nonpeak anomalies in a casing limits this safety analysis. Including nonpeak anomalies in this analysis requires excluding Companies B and G because they did not provide nonpeak anomaly data.

The casings of A, C, D, E, and F total 1,185. Of these 108 had a peak anomaly =20% WT. Of the 108 casings, 5 peak anomalies were recorded with FP/MAOP <1.39, requiring scheduled response per ASME B31G. For the 1,185 casings, anomalies <20% WT in depth totaled 2,553 (minimum depth recorded 5% WT), averaging roughly 2.15 anomalies per casing. Of the 2,553 anomalies, 38 were recorded with FP/MAOP <1.39 and none with FP/MAOP <1.1.

Fig. 6 shows (a) distribution of all anomalies vs. factor of safety of the above five companies irrespective of anomaly depth and (b) magnification of (a) near the lower end of safety factor (1.4 or less). The data suggest nonpeak anomalies can have a low factor of safety due to possible larger anomaly length. It is therefore highly likely Companies B and G have anomalies with FP/MAOP <1.39, even though such data were not available in this analysis.

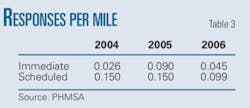

With the total length of 1,185 casings determined to be 22.58 miles (average casing length of 100.6 ft), the total of 38 anomalies with FP/MAOP <1.39 corresponds to 1.68 scheduled response/mile casing length, more than 10 times the 0.13 scheduled repair/mile of the INGAA study and 0.099-0.15 scheduled repair/mile in the PHMSA data for transmission pipelines (Table 3).8

Since it is unknown how many of the 38 anomalies would turn into defects scheduled for repair, the above comparison may not confirm cased crossings are less safe than noncased pipes but does raise the likelihood this could be true. The immediate repair/mile determined by the INGAA study equals 0.054 and in the PHMSA data between 2004 and 2006 (Table 3) equals 0.26-0.90. The immediate response for the cased segments studied is zero.8

Leaks per mile are another measure of pipeline safety, but these data are not available for this study.

References

- ASME, “Gas Transmission and Distribution Piping Systems,” ASME B31.8-1999 Edition.

- OPS, Technical Division, Interoffice Report-Project No. 87-6, May 10, 1988.

- Hennon, G.J., and Kimmel, A.L., “A Study of Cathodic Protection of Buried Steel Pipeline within a Steel Casing,” PR-138-83, Final Report from Midwest Research Institute to the Corrosion Supervisory Committee of the Pipeline Research Committee International of the American Gas Association, Arlington, Va., July 31, 1979.

- Rankin, L.G., and Al Mahrous, H.M., “External Corrosion Probability Assessment for Carrier Pipes inside Casings,” GRI Contract No. 8790 March 2005.

- Frazier, M.J., and Barlo, T.J., “Method for Assessing Electrical Resistance of Pipeline Casings,” PR-151-819, Final Report from Science Applications International Corp. to the Corrosion Supervisory Committee of the Pipeline Research Committee International of the American Gas Association, Arlington, Va., December 1989.

- PHMSA, “Corrective Action Order to Columbia Gulf Transmission Co.,” CPR No. 4-2007-1017H, http://search.yahoo.com/search;_ylt=A0geu4vCB_ZIUu0AKURXNyoA?p=Delhi%2C+columbia+gulf+transmission%2C+casing&y=Search&fr=yfp-t-501&ei=UTF-8, 2007.

- Process Performance Improvement Consultants LLC, “Comparison of Integrity Management Assessment Techniques for Natural Gas Transmission Pipelines,” INGAA Foundation, Report No. F-2007-09, 2007.

- Southwest Research Institute, “Statistical Analysis of External Corrosion Anomaly Data of Cased Pipe Segments,” INGAA Foundation, Report No. F-2007-10, December 2007.