COMMENT: Renewables not adaptable to large-scale installations

Proponents of renewable energies frequently say those energy forms will become economic when accomplished on a very large scale. This article will discuss the favorable economies of large-scale operations and describe how these economies do not apply to most renewable energy resources.

In addition, proponents of renewable energy claim that experience will reduce renewable energy costs until renewable forms are competitive with fossil and nuclear energy. This “learning curve” observation, which began in World War II for aircraft manufacture, quantifies the reduction in labor effort required to accomplish repetitive manufacturing tasks, and it has been extended to other circumstances. Its application to renewable energy is limited.

A previous OGJ publication discussed how manufacturing costs and energy costs move together in a 1.0 correlation on a log-log graph.1 OGJ refinery fuel and refinery inflation index data for over 70 years are utilized on a log plot to obtain the 1.0 correlation. This observation suggests that the source costs of renewable energy resources will increase in parallel with energy costs in general, and thus they cannot gain a cost advantage.

Large scale economies

The economies of large-scale operations range from large petroleum refineries and petrochemical complexes to personal shopping at Wal-Mart. This observation, published over 60 years ago, has been quantified in industrial processes as the “six-tenths rule” relating capital cost and capacity as follows:2

- Cost$ 2 = Cost$ 1 (capacity 2 / capacity 1) 0.6

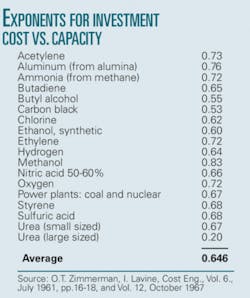

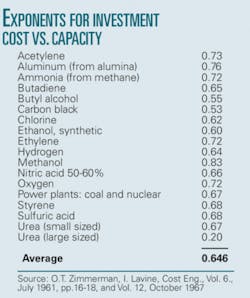

The value of the exponent varies with the processes involved, and values have been widely published. One example of these exponents is given in Table 1. The average value of the exponents in Table 1 is 0.65, differing little from the six-tenths rule. So if the capacity of a facility is increased by a factor of 3 the six-tenths rule says the required investment cost will be increased by a factor of only 1.9.

The underlying logic of the six-tenths rule can be illustrated by considering a low-pressure cylindrical tank or reaction vessel. Its cost is proportional to the area of material required for its construction, and its actual function in a process is proportional to its volume. For this reason at a constant length-to-diameter ratio, costs can be related to capacities via simple geometry to result in the following equation:

- Cost $ 2 = Cost $ 1 (capacity 2/Capacity 1) (0.667)

The above exponent of 0.667, two-thirds, is an approximate verification of the six-tenths rule, and it is calculated only with considerations of geometry.

Labor requirements are proportional to the 0.2-0.25 power of plant capacity, according to a reference cited by F.C. Jelen.3 This greatly reduces the labor requirement for larger plants, again making it more difficult for smaller facilities to compete with large facilities.

Extrapolating the rule

As with all extrapolations, extrapolation of the six-tenths rule must be done with great caution. When extrapolated to larger sizes, several constraints may apply:

- The capability to fabricate, transport, and install larger process equipment items limits the size of processing units. The realistic expedient is multiunit processing units and multitrain processing facilities. This practice eliminates much of the economies of scale indicated by the six-tenths rule.

- Difficulty in scaling up solids processing facilities, so multiple units are used. An example is the Lurgi gasifiers for coal used in the South Dakota coal gasification facility. Oil shale retorts have the same constraints. This constraint is also demonstrated by construction of many duplicate wind turbines in a row, rather than just one exceptionally large one.

- Availability of raw materials and the shipping charges associated with them. This constraint applies to many biomass processes as well as the processing of oil and gas at their initial production sites.

- Impact on the product market from a new, large-scale facility. The result may be closure of smaller facilities producing the same product.

These constraints limit the practical size of a processing facility, and that size limit is termed a “world-scale” facility. The size of the ideal “world-scale” facility may increase as new demands and technologies develop.

Extrapolation also fails when the six-tenths rule is extrapolated to smaller processing facilities. In the case for smaller sized facilities, the number of things—valves, instruments, and controls—remains constant, so little or nothing is really gained by attempting to make a smaller facility, hoping that it will be somewhat less costly.

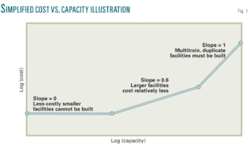

These “large-size” and “small-size” constraints on the six-tenths rule are illustrated in Fig. 1. The constraints are a part of the real world today. Persons considering a new larger or smaller facility must decide where they are positioned on the curve in Fig. 1. Intentionally, there are no numerical values on the X and Y scales of the figure because values differ for each process and facility. This circumstance will be applied to alternative energies in this article.

The learning curve

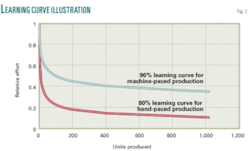

The learning curve is another empirical observation that can be cited to justify hoped-for reductions in costs for renewable energy sources. It was observed and quantified for aircraft production during WWII. H.J. Behrens has discussed its mathematical details.4 Simply stated, every time commercial production of an item is doubled, the effort required for production of the next unit is an empirical fraction of the effort for the final unit of the previous “doubling.” W.B. Hirschmann generalized this observation as 80% for human paced production and 90% for machine-paced production (Fig. 2).5

This learning curve concept applies to commercial production. During research and development, estimated per-unit costs frequently increase due to making more-detailed designs and associated difficulties. This circumstance has been termed the negative learning curve and may apply to present noncommercial alternative energy sources.6

Note that the number of units required to “double” production continues to double, also, so the cost reduction of the learning curve is much diminished after production of huge numbers of units as Fig. 2 illustrates.

Solar energy

Solar energy has the potential of supplying US electric power needs with modest levels of land usage, but its investment cost and intermittent availability have prevented large scale commercial usage for supplying the electricity marketed by utilities.

Solar collectors of all types are rated on the area that intercepts the sunlight. For this reason they do not have the noted economies of larger-scale operations.

Some large-scale economies can be achieved in the conversion facilities that utilize the energy collected by solar collectors. So buying solar collectors is somewhat analogous to buying carpet by the square yard or meter except that a photovoltaic solar cell is a sophisticated, semiconductor device—a flat, very large junction formed between P-type and N-type semiconductor materials.

Small solar cells can be installed on roofs of both commercial and residential buildings with little penalty for small-scale operations except the cost of the “interface” that connects them to the utility grid or to a residence. These installations are costly, so they remain dependent on support by regulations, subsidies, and the environmental concerns of individuals.

Solar-thermal power generation facilities substitute mirrors for semiconductor-based solar cells. They acquire the cost of continual re-aiming the mirrors at a receiver on a “steam” boiler, and are burdened with the thermodynamic inefficiencies inherent with all “heat engines.” There are economies of large-scale operation to the extent that large mirror “fields” are practical.

The mechanical and optical problems associated with solar-thermal power generation are solvable with existing technologies, but the resulting high costs have prohibited widespread commercial applications.

Other constraints on solar energy include a low intensity relative to industrial furnaces—1/500 according to one reference.7 In addition, sunlight is intermittent—when it is needed most for heating buildings and light, the sun has set.

Intermittency limits the fraction of time that the investment made in solar collectors can be used for a financial return on the investment.

The inherent high cost of the electricity generated from solar energy, however, should not deter architects and home-builders from including passive solar energy management in their buildings, where economic.

Wind energy

The problem of intermittency and electric power storage must be considered for another renewable energy source—wind.

Wind energy has the potential of supplying a large portion of US electric power requirements with a minimal amount of land usage, just as with solar energy, but it meets with the same constraints of being intermittent and variable. It cannot gain the full six-tenths rule economies of large-scale operation, as demonstrated by the long rows of duplicate wind turbines being installed. This multiplicity of units does gain reduced costs via the learning curve for the replication and installation of near duplicate units.

A typical large wind turbine farm consists of several hundred thin towers 35 stories high topped with 65 tons of mechanical and electrical equipment for production of 1.5 Mw of electricity each at the design wind speed. The blade span is longer than a football field, and the blade tips travel at about 200 mph. This rotating equipment must be maintained on each tower.8

Simple design concepts for wind turbines consider the fact that power production is proportional to blade length squared and that the potential power available is proportional to the wind speed cubed, so a 12 mph wind contains 73% more energy than a 10 mph wind.

Variations in wind speed become the challenge in the selection and design of wind turbines. They often are designed for a selected wind speed that is frequently reached, with feathering of the blades when that wind speed is exceeded in order to maintain a constant power output consistent with the mechanical and electrical design of the wind turbine.

So selecting the design point wind speed is crucial, but good data are not always available. In addition there is no assurance that a selected wind speed will remain optimal during the expected 20-30-year life span of the turbine.

The wind is already kinetic energy, so it not constrained by the thermodynamics of “heat engines.” But it is constrained by the need for the “exhausted wind” to move away from the rotor, limiting the theoretical efficiency to about 60%. Due to mechanical losses, the overall efficiency is closer to 35%.9

Since wind is abundant, this relatively low efficiency is not crucial, but it does require additional investments for a particular output power capacity.

A more important concern is the variable and intermittent nature of the wind, which enables the turbine to produce only a fraction of its possible “nameplate” power in a particular year. The actual number of kilowatt-hours sold during the year will be only a fraction of the nameplate rating of the turbine. One reference gives this factor as one-third.10 Therefore, when investments are given for wind power in terms of installed megawatts, the dollar value should be multiplied by three before comparing it to nuclear or fossil energy investments per megawatt installed.

If wind energy becomes a major fraction of the electric power generated, another major cost is incurred—maintenance of reserve generating facilities, even “rotating reserves,” for when the wind stops blowing at the wind farm. Texas almost experienced a “brown-out” in late April 2008 when a “no wind” event occurred in conjunction with other grid concerns.11 12

Ocean waves and tides

The ocean represents four fifths of the surface of the earth, and humankind has always been impressed with the kinetic energy contained in the moving water of the waves and tides.

Still, the mechanical technology has not been demonstrated to routinely convert this immense available energy source into economic electric power. There has been very limited success with tides, which are cyclic, depending on the relative position of the moon.

There has not been commercial success with waves, however. Waves are a reciprocating motion that vary greatly in height and so require considerable mechanical apparatus to convert them to steady rotary motion needed for electric power production.

A recent newspaper review briefly cited efforts with waves and tides for energy and listed their mechanical and environmental problems.13 A cost of 40¢/kw-hr was cited in one case, and many of the projects projected their major demonstrated results into the future. Neither wind nor waves have the economics of very large-scale operations available to them because they are both local and cyclic.

Storing electric power

Wind and solar power both require economic and efficient large-scale storage and transmission of electricity. In favorable locations, limited power storage is accomplished by “pumped storage” at hydroelectric facilities. Water is just pumped back up to the dam when there is excess available power, so it will be available to generate addition power when it is needed. If the efficiency of both the pump and turbine are 90%, the resulting power storage is 81% efficient. This option for power storage is not generally available, however.

Small-scale electrical storage techniques such as batteries and capacitors are not economically adapted to large-scale power storage. Electrolysis of water to hydrogen and oxygen with wind or solar power has not been demonstrated on an effective scale despite past efforts, although there are current efforts in this regard.14

Larger electric power grids are a partial solution, and that option may include high-voltage direct current as a power transmission method. Still there is a strong need for large-scale storage of electric power from both wind and solar, which may prove physically impossible.

Compressed air was recently illustrated as a means of storing power, with a commercial installation in Alabama cited.12 Natural gas-fired turbines are well adapted to power storage because the air compressor on the gas turbine requires about 60% of the expanders’ horsepower output, leaving only 40% for net electric power generation. Substitution of stored compressed air for turbine compressed air ideally releases this 60% of the turbine power for generation of additional electricity. When electrical demand is decreased, air can be compressed and stored for future use.

There are solvable mechanical problems associated with these arrangements and several options for their implementation, including direct compression of air by wind turbines. The major concern is economical storage of large volumes of compressed air. Several options for storage are available such as salt domes, depleted mines, or mined caverns. Optimal economic design of such storage units is not a simple task.

Nuclear explosives can very directly produce air storage caverns with known technology. The author has five patents for retorting oil shale shattered with nuclear explosives to form a deep vertical cylinder of broken shale known as a nuclear chimney. One example patent is referenced.15 These inventions could be readily modified to store compressed air simultaneously with retorting oil shale and even producing hot combustion gases for the expansion turbines. Because there are several nations developing nuclear weapons in defiance of world pressures, US restraint in not using nuclear explosives for peaceful purposes perhaps should be reconsidered.

Enhanced geothermal

Geothermal energy circumvents the problems of intermittence associated with renewable wind and solar energy. Where available, it provides electric power conveniently, so Italy, Iceland, and the western US have considerable geothermal power production facilities. This limited-availability resource has already been largely developed. Conventional geothermal energy depends on the coincidence of permeable hot rock and hot water, not a frequent occurrence.

Enhanced geothermal systems (EGS) depend only on the availability of hot rock at some economically drillable depth. Cold water is injected via an injection well into the hot rock whereupon production wells produce hot water for power production. The water circulation process is aided by making numerous hydraulic fractures in the hot rock. The technique was briefly demonstrated at the Fenton Hills site in New Mexico around 1990. Commercial power was not produced at that time.

However, the Fenton Hills personnel, among others, have continued their interest in EGS, and information regarding increased interest in EGS is available on the internet (Potter Drilling or Altaenergy).

EGS should be considered on par with other renewable energy resources. Much effort is required for EGS’s commercial implementation. It offers the advantages of being continually available and of making a small footprint on the land and adjacent environment. Some problems exist such as corrosion and silica solubility in very hot water. Petroleum production and drilling technologies easily support development of EGS.

EGS is constrained by the energy content of hot rock. A 50 Mw-equivalent power plant, for example, would daily have to remove the thermal energy from as much as 850,000 cu ft of hot rock in one set of assumptions. The thermal conductivity of rock is rather low, so extensive and controlled hydraulic fracturing would be necessary, not an easy task.

A more challenging and interesting task would be to drill into the magma region near a volcano. Drilling should be done with water as the drilling fluid under very high pressure. The result would be local cooling as the water flashes through the drillbit jets, resulting in high-pressure steam for geothermal power production. One well, gradually drilled to increased depths, could continually produce large volumes of steam for geothermal power.

Biomass

Biomass residues can be used as boiler fuel, and the forest products industries use their residues as boiler fuel for their own internal consumption, but the byproduct may have other value, including returning it to the land.

Both gathering and transporting biomass residue constrains the size and associated economies of scale of electric power generation facilities. Recently announced facilities produce only 50 Mw of electricity.

Liquid fuels from biomass—fermentation ethanol and biodiesel—are supported by federal regulations and subsidizes, and agri-industries and farm groups lobby for them in Congress. However, these biomass transportation fuels should not even be considered for favorable federal and state support as long has they are developed with the use of fossil fuels.

The net energy from fermentation ethanol that exceeds the fossil energy inputs is a matter of considerable debate. One author averaged several studies of net energy from fermentation ethanol production and found it to be a negative 2%.18

Other carbon sources

Petroleum is the dominate source of liquid transportation fuels. In addition, compressed natural gas is receiving increased attention as a transportation fuel. There are several other sources of organic carbon for transportation fuels such as coal, tar sands, oil shale, and black shales.19

Furthermore, even marginal petroleum reservoirs, deep offshore reservoirs, and sophisticated enhanced oil recovery techniques may yield oil and gas at costs below that of many of the energy alternatives discussed in this article.

No energy independence

This article has noted many difficulties with our nation’s becoming “energy independent” using particular domestic options other than nuclear—which is beyond the scope of this article (France, however, has shown that nuclear energy remains an excellent choice for electric power production).20

It is impossible for the US to be “energy independent” using only domestic fuels.21 Newspaper columnist, John Stossel, has made similar observations.22

Renewable energy resources are very much constrained by the impossibility of their ability to be scaled up to power huge facilities such as refineries and (currently coal-fired) power plants.

The “learning curve” is limited in reducing the cost of renewable energy due to repetitive activities. Investment costs frequently increase when energy costs increase.

Renewable and alternative energy resources will not become competitive with fossil and nuclear energy without continued major government subsidies—a drain on US taxpayers and on the national economy.

References

References are available from the author at [email protected].

The author

Harry W. Parker ([email protected]) is professor emeritus of chemical engineering, Texas Tech University. He has been involved in energy-related research at many levels, including in positions with Phillips Petroleum Co. and Washington, DC, research organizations. He was associate and full professor in the Texas Tech University Department of Chemical Engineering from 1970 until his retirement. In November 2008 Parker was awarded the Technology Innovation Award by the Brazosport section of the American Chemical Society. He holds degrees from Texas Tech University and Northwestern University.