Study examines effect of cetane improvers

An investigation of the effect of cetane improvers on diesel cetane number showed that diesel fuels have a low sensitivity to the additives.

Hydrotreated straight-run gas oils from Ural crudes, and their blends with hydrotreated secondary gas oils like light cycle oil (LCO), heavy cycle oil (HCO), and visbreaker gas oil (VBGO), exhibited an increase of 0.28 cetane numbers at a 100-ppm cetane improver (2-ethyl hexyl nitrate) treating rate. This was typical for these diesel blends.

Diesel cetane

According to the European diesel standard EN-590, diesel in the European Union must have a cetane number no lower than 51 and a cetane index no lower than 46. Cetane index is a correlation that predicts cetane number of diesel that does not contain cetane-improving additives.

According to ASTM D-4737, the cetane index is calculated using the density at 15° C., T10, T50, and T90 from the ASTM D-86 distillation of the diesel fuel. There is therefore a limit for the minimum cetane number of the base diesel fuel that could be treated with cetane improvers to achieve the specified value of 51. Production of automotive diesel in a refinery consists of blending of hydrotreated straight-run and secondary middle distillates.1 Unlike straight-run diesel fractions, secondary gas oils have lower cetane numbers.

Continuing dieselization in Europe is forcing refiners to look for ways to extend the feed base for production of automotive diesel.2 The relative share of secondary diesel fractions in the refinery diesel pool will therefore increase because straight-run middle distillate fractions are limited by the processed crude.

Typically, refiners cannot achieve a cetane number of 51 for the diesel pool due to the presence of hydrotreated secondary diesel fractions; therefore, refiners use cetane improvers. The most widely used cetane improvers are those based on 2-ethyl hexyl nitrate (2EHN).

The effect of cetane improver treating rate depends on the base diesel fuel cetane and composition (OGJ, Dec. 3, 2007, p. 58). Different sources, however, have indicated different dependence rates.3

Keeping in mind the increasing share of secondary gas oils in the diesel pool, we carried out a study to determine the dependence of base diesel composition and cetane number on the efficiency of cetane improvers. This article discusses results of our study.

Experimental

We used hydrotreated middle distillate fractions from the Lukoil Neftochim Bourgas (LNB) hydrotreating units, unhydrotreated straight-run gas oil (SRGO) from one of the LNB crude distillation units, and unhydrotreated LCO and HCO from the LNB FCC unit in this study.

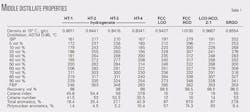

Table 1 shows the physical and chemical properties of the middle distillates studied. We analyzed the total aromatics and polynuclear aromatics in the gas oils according to EN-12916.

We determined diesel cetane number in accordance with ASTM D-613. Cetane index was calculated in accordance with ASTM D-4737. We used a commercial sample of 2EHN as the cetane improver.

Cetane improvers

Cetane number increases with higher molecular weights and lower aromatics content of the diesel fuel studied. The diesel fractions we studied vary considerably in term of distillation range; therefore, we used hydrocarbon composition in this study.

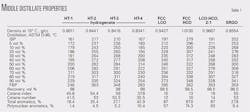

Cetane number of the investigated diesel fractions varied between 12.0 and 53.5, the total aromatics content varied in the range 18.4-87.0%, and the polynuclear aromatics varied between 1.4% and 74.3%. We prepared six blends of these diesel fractions (Table 2).

We obtained hydrogenates from the four LNB middle distillate hydrotreating units by hydrotreating these middle distillate fractions:

- HT-1 = SRGO (180-240° C.).

- HT-2 = SRGO (240-360° C.), SRGO (200-300° C.), VBGO.

- HT-3 = SRGO (240-360° C.), light vacuum gas oil (LVGO).

- HT-4 = SRGO (180-240° C.), SRGO (200-300° C.), FCC LCO.

We obtained SRGO from crude distillation units that were feeding Ural crude. Properties of the hydrogenates from the four LNB hydrotreaters in Table 1 indicate that the hydrogenate from HT-4 had the lowest cetane number. This hydrogenate had the lowest cetane number because the HT-4 unit processes a feed that contains about 25% FCC LCO.

The same hydrogenate also had the highest aromatics content. This can explain why the blend containing the most HT-4 hydrogenate had the lowest cetane number, 44.1, while the blend that contained the least HT-4 hydrogenate had the highest cetane number, 51.0.

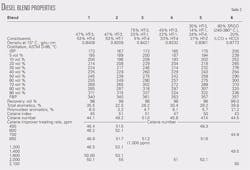

Table 2 shows how the cetane number of the six blends reacts to an increase in the cetane improver's treating rate. These data show that the diesel cetane number of studied blends is not highly sensitive to cetane improvers.

All the investigated diesel blends exhibited the same rate of increase in cetane number with more cetane improver used.

The figure shows that the slope is 0.0028 for all blends, which means that a cetane increase of 0.28 will result with every 100-ppm cetane improver added.

Unhydrotreated SRGO (240-360° C.) with a base cetane number of 53.0 exhibited the least sensitivity to the cetane improver: a cetane increase of 0.18 at 100 ppm additive rate.

These results differed considerably from those reported by Morris (OGJ, Dec. 3, 2007, p. 58). He reported a cetane number increase of 1.2 at 100-ppm cetane improver 2EHN treating rate for a diesel with a base cetane of 43.0.

Adding 25% LCO to the same base diesel fuel reduced its cetane number to 36.9 from 43.0 and reduced the diesel sensitivity to the cetane improver to 0.5 from 1.2 cetane numbers.

The difference in observations is probably due to the type of crude processed. Obviously, middle distillate fractions from Ural crudes exhibit a lower sensitivity to treatment with a cetane improver and this sensitivity does not change when treating a highly aromatic FCC LCO.

This can explain some curious results—for example, adding 1,000-ppm cetane improver to Blend 4 had no effect. According to other results, Blend 4 should have increased 2.8 cetane numbers.

In accordance with ASTM D-613, the repeatability of cetane number measurements was 0.9 and the reproducibility was between 3.3 and 4.8 for the range of cetane numbers studied. In some cases, cetane numbers of the studied blends were measured in different laboratories; therefore, a difference in the cetane number less than 3.3 may not have been recorded.

Acknowledgment

The authors thank Saybolt Bulgaria and SGS Bulgaria for measuring the cetane numbers of diesel fuels used in this article.