Special Report: Biomonitors assist smooth pipeline project schedule

Using biomonitors (qualified on-site biologists with construction expertise) can lead to successful negotiation of contentious environmental issues and full compliance with regulatory conditions and permit stipulations. Southern Natural Gas Co., an El Paso company, used biomonitors to ensure full environmental compliance with regulatory conditions associated with the construction of the Cypress Pipeline project.

Biomonitors allowed environmental compliance issues to be handled in advance or avoided entirely, rather than cropping up unexpectedly during agency inspections or after irreparable damage had been done. The biomonitor system ensured a smooth construction schedule with regard to environmental issues, resulting in significant overall time and cost savings for the Cypress project.

Southern engaged in extensive consultation and negotiation with federal, state, and local regulatory agencies while preparing for the project. Southern used two biomonitors in successfully negotiating contentious environmental issues and fully complying with specialized compliance conditions stemming from the regulatory and permitting processes.

This article details the role of these biomonitors.

Background

The Cypress project called for construction of a 167-mile, 24-in. OD pipeline from just east of Savannah, Ga., to west of Jacksonville, Fla., including five gas-delivery interconnects and three compressor stations. Cypress is a take-away pipeline from Southern’s subsidiary, Southern LNG Inc., an operating LNG import and storage terminal located in Savannah.

The selected pipeline route through coastal Georgia and Florida contains some of the most ecologically-sensitive regions in the country. Cypress crossed more than 300 wetlands; 40% of the route (60 miles).

Cypress also crossed more than 200 water bodies; six more than 100 ft long and requiring specialized construction techniques.

null

The project area served as habitat for more than 24 protected species, 13 of which were found along the project route. Biological surveys conducted before construction identified more than 200 gopher tortoise burrows, for example (Fig. 1). The project area also contained several significant historical sites and essential fish habitat for managed fisheries.

Agency consultation

Southern consulted with many different federal, state, and local agencies, including the Federal Energy Regulatory Commission, US Fish and Wildlife Service, National Marine Fisheries Service (NMFS), US Army Corps of Engineers, Georgia Department of Natural Resources, Florida Department of Environmental Protection, the Saint Johns River Water Management District, and others. The environmental resources identified along the Cypress route required creative solutions to the numerous (sometimes conflicting) agency requests regarding avoiding or minimizing environmental impact.

Southern conducted specialized species surveys during preconstruction, relocated protected species, set up exclusion fencing to keep protected species from entering the construction zones, and implemented various other techniques and practices. Southern also manipulated construction windows to avoid foraging and nesting periods for several protected bird species and withdrawing water for hydrostatic testing during spawning events.

Trenchless technologies such as horizontal directional drilling allowed Southern to build underneath significant ecological habitats and historical sites. As part of a specific condition to comply with the NMFS approval, Southern used specially engineered hydrostatic test intake structures to reduce water velocities to 0.5 fps, preventing entrainment or other damage to eggs, larvae, and juveniles of protected fish species.

Agency assurance

Each agency wanted assurance that its proposed avoidance or minimization techniques would be fulfilled correctly. Southern explained that a team of third-party environmental inspectors would be on site to monitor construction and make sure that the permit conditions would be upheld, but the agencies remained concerned that the inspectors would not have the qualified biological background necessary to perform the identified compliance practices.

Southern proposed using biomonitors, in addition to the team of environmental inspectors, to meet all agency consultation and permit conditions. The biomonitors had specialized construction experience and would remain in the field during construction.

Introducing the biomonitor concept increased agency cooperation during consultation.

Results

Southern defined a biomonitor as a professional, possessing an advanced degree in biology or the environmental sciences, tasked with project monitoring to ensure compliance with environmental conditions by communicating and coordinating with the company, inspection, and contractor personnel. Southern used two biomonitors for the Cypress project.

They provided the project with environmental compliance advantages. They routinely participated in morning construction meetings, during which they alerted construction personnel to specific immediately applicable environmental permit conditions or compliance. Biomonitors notified the construction team if a protected species window was approaching and ensured that either activities ceased during these windows or work was completed beforehand. They also reminded the construction team which waterbodies required specially engineered intake structures during hydrostatic test withdrawals.

Biomonitors surveyed construction areas for sensitive environmental resources before each phase of activity, fostering proactive communication with the construction crew before environmental issues arose. The Cypress construction team avoided several protected species or rescued them from harm’s way via this method. Biomonitor scouting also protected construction personnel from animals such as venomous snakes (Fig. 2) and alligators (Fig. 3).

The construction team occasionally needed additional workspaces, contractor yards, or access roads. Such unplanned alterations result in suddenly scrambling through an agency variance process, because environmental issues are usually not in the front of the construction team’s thought process when varying from the original plan.

During Cypress, however, biomonitors performed necessary biological surveys and prepared construction variances for agency approval as changes happened. Biomonitors also worked directly with the agencies to manage the variance processes in the event a construction deviation was required.

Georgia and Florida have several water-quality protection permits requiring state-certified personnel to monitor water quality, take water samples, and prepare resulting reports. Cypress biomonitors held certificates from Georgia and Florida allowing them to perform these tasks, and were crucial in meeting state water quality requirements.

Biomonitors also acted as liaisons during agency inspections, escorting agency personnel during construction audits. The biomonitors standing as trained biologists already entrenched in the construction process allowed them to respond readily and articulately to specific environmental issues related to permit conditions.

The authors

Jason Goldstein ([email protected]) is vice-president of environmental affairs for the Atlantic Sea Island Group’s Safe Harbor Energy LNG Project, based in Manhattan, New York. He also worked as a principal environmental scientist for the El Paso Corp. Jason has over 15 years experience as an environmental manager. Goldstein holds a BS in biology from Keene State College, New Hampshire, and an MS in environmental science from SUNY College of Environmental Science and Forestry at Syracuse University. Jason is a registered environmental manager and a certified professional in erosion and sedimentation control.

Editor’s note: Jason Goldstein worked at El Paso Corp. when this paper was written.

Rebecca Goldstein ([email protected]) is a medical writer for the medical & scientific services group of Gardiner-Caldwell US. She earned her PhD in cell biology from the University of Alabama at Birmingham, where her research included characterizing targeted molecular therapies for cystic fibrosis and HIV. She has 7 years of research experience in the fields of cellular immunology and protein trafficking.

Correction

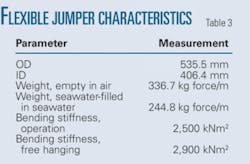

In the article “Hybrid riser application provides deepwater crude export solution” by Francisco E. Roveri, A.G. Velten Filho, V.C. Mello, and L.F. Marques, Table 3 (OGJ, Nov. 10, 2008, p. 62) contained errors. Following is a corrected version of the table.

null