Shallow-water gas network navigates multiple problems

Design and installation of the offshore portion of Bahrain Petroleum Co.’s Khuff gas transmission and distribution networks (three 18-in. OD high-pressure natural gas lines) required careful planning and implementation to avoid damaging fisheries and migratory bird stops located in the shallow-water environment and impeding shipping through the commercial channel.

The offshore segment links the wharf valve station at Sitra to the Hidd metering station, roughly 6 km away on the east side of Bahrain’s Muharraq island.

This article details problems related to the protection of the environment during construction and subsequent commissioning of the pipelines. The article will also present construction methods used, including steps taken to maintain access to Mina Salman port via the shipping channel and detail the design, construction, installation, and commissioning of these three 18-in. pipelines through shallow inshore waters and across the only shipping channel to the port of Mina Salman.

Background

Bapco began expanding the Khuff gas transmission and distribution networks in Bahrain in 1996, seeking to increase gas delivery to meet rising demand for natural gas for power generation and other local industries.

Offshore pipelines emerged as an option to provide gas to a new power station in the Hidd area and to customers encouraged to participate in Bahrain’s development. These projects included both the increase in electricity and desalinated water supply and development of the Hidd Industrial Area and Sheikh Khalifa bin Salman deepwater port.

Other options for gas transport included laying pipelines from near the Sitra power station or across the newly built Sheikh Khalifa causeway and bridge.

Consultation with government bodies and engineering companies prompted the decision to lay three parallel pipelines across the channel from a point near Bapco’s Sitra tank farm and marine terminal, terminating at Hidd Industrial Area, 1 km north of the Arab Shipbuilding and Repair Yard (ASRY).

Offshore requirements

Initial steps in determining offshore requirements also included a gas network analysis of what additional transmission pipeline links would be required to improve flow rates and maintain delivery pressures to the distribution system. This review determined an additional five gas transmission pipelines, running parallel to existing pipelines, would be required in the Bahrain field area. Customer locations and requirements provided the basis for the distribution system review. The review also determined the need to both upgrade existing and install new distribution and metering stations.

Offshore detail

The pipeline system needed to deliver 475 MMcfd at no less than 500 psig. Plans considered the sensitive location, maintenance, and security of supply. The decision to install three pipelines provided 100% redundancy.

The location of the pipelines and proposed future development in the area highlighted the need to use ASME B31.8 Location Class 3 and 4 design criteria, supplemented by Det Norske Veritas requirements for offshore submarine pipelines.

Theses codes classified the first 4,000 m of pipeline, located near the Sitra Marine terminal and Sitra Island, as Location Class 4 and the remaining section running across QAQ Island to the Hidd metering station as Location Class 3. The design required the pipe be purchased in two thicknesses; 10.3 mm and 12.4 mm. Pipe consisted of API 5L Gr. X52 PSL2, coated with a three-layer polyethylene system.

Design of the pipeline required a concrete weight coating to overcome buoyancy factors and provide mechanical protection. Installation at an invert depth of 3 m required extensive trenching with a dredger in the deepwater channel and tracked machinery in the shallow-water areas.

Offshore needs

The coastal marine environment of Bahrain is important to the local people. They have been fishing in both the shallow and deep waters of the area for generations. Bapco sought to protect this marine environment during front-end engineering and design and conducted environmental impact studies. Shallow-water fish traps needed to be moved for trenching and pipelay, and local fishermen had to be considered and alternative locations for traps provided.

QAQ Island was also home to migrating terns. Bapco considered the effect of installation work on the terns’ nesting practices. The contractor was obliged to return marine and island habitats to their original state on completion of the project.

Crossing the Mina Salman navigation channel required caution, as it is the only means of accessing the port of Mina Salman. Planning and execution of the crossing required communication with and cooperation of the port authority, coast guard, and Bahrain defense force. All parties had to agree to scheduling of pipe trench works and pipe pulling. Penetration of the freshwater aquifer also had to be avoided. This aquifer lay only a few feet below the target depth of the pipelines at places in the deepwater channel.

Facilities of three major utilities also required crossing. These crossings were:

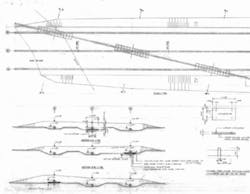

- Electricity Distribution Directorate power cables-pilot cable close to QAQ Island (Fig. 1). These 66 kv cables, located on the north side of QAQ, provide power to ASRY dry dock, AISCO iron ore pelletizing plant, and other residential-business users. Bapco placed severe restrictions on the contractor relating to scheduling of the work on the crossing, protecting the cables from damage, and maintaining the minimum vertical clearance.

- Existing 10-in. gas line on QAQ Island (Fig. 2). This gas pipeline supplies high-pressure Khuff gas to the AISCO iron ore pelletizing plant and had to be crossed on the south side of QAQ Island. Maintenance of gas supply to this customer was important and Bapco took measures to avoid damaging the line and potentially interrupting service.

- Hidd dry dock road, adjacent pipelines, cables, and services. This four-lane highway provides the only land access to ASRY dry dock and is adjacent to power, telephone, and water services. Onshore activities at Hidd included installing a metering station and pipelines to customers. These pipelines ran at right angles to the offshore pipeline and had to be crossed.

Onshore fabrication

Bapco established an onshore fabrication yard (Fig. 3) for welding pipe joints into strings about 348 m long, building a total of 51 strings. Fabrication included welding pipes together, weld inspection, holiday testing of coating, pressure testing, concrete weight coating installation, heat shrink sleeve application, and bracelet aluminum anodes installation.

Setup within the pipe yard allowed completed strings to be rolled across the pipe racks to the launch ramps, where pipe strings were gathered in order of laying. The two thicknesses of pipe required they be arranged in the correct order for pulling and launching. Following fabrication, Bapco prepared the pipes for launching into the sea via a preinstalled access way under the dry dock highway.

Offshore excavation

Offshore activities included excavation of the trench from the pipeline’s wharf valve station to and across QAQ Island with tracked excavators. The excavators either created their own causeway with excavated fill or were loaded onto barges (Fig. 4). A barge-mounted grab bucket and dredger completed excavation and trenching across the shipping channel.

Trenching works in some of the shallow waters from the WVS to QAQ Island could occur only at low tide and during daylight hours with tracked excavators (Fig. 5-6). Some shallow-water fish traps also needed to be removed in coordination with owners and marine organizations.

Extra care was taken where the new lines crossed the 10-in. line supplying high-pressure gas to the iron ore pelletizing plant at the southern shore of QAQ Island (Fig. 7). Precautions included installation of marker posts or buoys along the 10-in. gas line and 8-in. jet fuel line. A pipeline locator, followed by hand excavation of trial holes, determined the exact location of the jet fuel line.

Preserving the integrity of the local freshwater aquifer, which lay only a few feet below the bottom of the trench in the area of the shipping channel, required close monitoring of excavation activities and liaison with the water resource directorate.

Pipe positioning

Launch of each of the 51 strings took place from the pipe yard through the pipe launch system under the dry dock highway. Casings installed under the highway used the open cut method. Rollers installed on either side of the casing helped launch the strings.

A 300-mt capacity linear gripper winch bottom pulled strings in trenches near WVS. These winches worked from a barge anchored in shallow water. They ran along the trench through QAQ Island and across the marine channel. On QAQ Island rotating guides allowed the pipes to negotiate the curve on the island. Buoyancy aids attached to each string reduced the submerged weight while maintaining negative buoyancy and stability.

The capacity of the winch proved to be inadequate during the first bottom pull. The pipeline contractor decommissioned the pipe pull barge and located a 200-mt capacity winch spread on QAQ Island. Flotation devices again provided some buoyancy. Pulling each string from the yard entailed welding the next string to it, performing NDT on the weld, applying heat-shrink sleeves and concrete weight, and then resuming the pull. This sequence installed the pipeline on the bottom of the trench from QAQ Island to the dry dock highway crossing.

Shallow waters in the area between WVS and QAQ Island required each string be floated into position on the surface. All activity related to the pulling or floating of strings from the fabrication yard ran through the various marine agencies to ensure shipping was not unduly affected.

Offshore welds

Fabricating the pipeline in sections required several tie-in welds over the offshore trenches. Floating pontoons supported these tie-ins. The pontoons floated above the tie-in point and the two sections to be joined were rigged and lifted out of the water. Workers removed end caps, completed pipe-end preparation and completed the tie-in weld. This process required marine, rigging, fabrication, welding, inspection, diving, coating, and concrete weight coating services be available on the pontoon at various times during the tie-in work. Lowering the pipe into the trench ensured correct alignment (Fig. 8).

Postinstallation surveys

Following installation, divers conducted a line survey including video to ensure the three pipelines were in the correct location and minimum distances between pipelines had been observed. Barge-mounted cranes made any necessary corrections to properly align the pipes. Permission to backfill the trenches occurred only after verification the pipelines had been laid in the proper location.

Application of a protective rock layer followed backfill, addressing the tendency of ships to drag anchor in the marine channel area.

Hydrostatic testing

Following construction activities, including installation of pig launching and receiving facilities at each end, the pipelines underwent various swabbing activities to clean them internally and confirm roundness had remained within specification. Specification for the gauging plate was 95% ID.

The pipeline contractor enlisted the assistance of the Bahrain civil defense fire service to expedite swabbing and pigging. The fire service provided newly acquired fire trucks and pumps to fill the line with water. This not only provided a reliable pumping system, but also gave the fire brigade the opportunity to severely test newly acquired equipment.

Repairs

Swabbing and gauge plate runs revealed the easternmost pipeline had a serious obstruction, either internal or external. The pipeline contractor recruited a specialist company to smart pig the line and locate the obstruction, following other efforts to address the blockage via conventional pigging.

Locating the obstruction with a combination of information received from the smart pig and closely monitoring the amount of water used to push the pigs to the obstruction allowed precise reexcavation of the pipeline and confirmation of external damage by divers. Subsea repair entailed cutting out the defective pipe and replacing it with sound pipe. The relatively shallow depth allowed air-supplied hypobaric welding (Figs. 9-10).

Contractors completed the swabbing and hydrostatic testing of the other two pipelines during this repair work. Following repair, they also satisfactorily hydrotested the third line.

Commissioning

Superdry air (dewpoint, 20° C.) dewatered and dried the pipelines following construction and inspection. Nitrogen purged the pipelines before gas was introduced. Bapco’s gas operations section handled final commissioning.

The author

David McGlone ([email protected]) is senior inspection engineer at Bahrain Petroleum Co., Kingdom of Bahrain. He has also served as inspection engineer, head services engineer, and quality coordinator at past companies.