New fluids prevent formation damage to Tarim sandstones

Researchers at China University of Petroleum have developed new drilling and completion fluids to minimize damage in Jurassic sandstones.

This work addresses the characteristics of geological structure, lithology, permeability, porosity, and mineral components of a typical high-pressure, low-permeability, dense reservoir formation in China’s Tarim oil field.

The main types of damage in these low-permeability formations are water-blocking and stress sensibility.

Numerous studies have shown that the extent of water-blocking damage ranges from 70% to 90%,1-5 and stress-sensitivity damage ranges from 25% to 60%.6

In a laboratory setting, China University of Petroleum developed new low-permeability drilling and completion fluids composed mainly of highly effective surfactants, temporary plugging agents, various types of bridging agents, and polyether glycol.

Both laboratory evaluation experiments and field tests have shown that the new low-permeability KCl sulfonated polymer drilling fluids are suitable for high-pressure exploratory wells. The permeability ratios (Ks′/KS) of cores from a test well drastically increased after use of the new drilling fluids.

In addition, the new, low-damage drilling fluids have many other advantages such as good rheological properties, high temporary plugging effect, and low filtration.

This article introduces characteristics of damage for low-permeability, high-pressure, tight sandstone reservoirs in Tarim oil field and presents the approaches to prevent damage during drilling and completion operations.

Target reservoirs

Low-permeability reservoirs, including microfractured reservoirs, are commonly characterized by thick mud cake, complicated structure, high sensitivity to invasive fluids, high capillary pressure, water-blocking, anisotropic target formation, and high flow resistance. They have lots of natural microfractures, leading to stress sensitivity.

Water sensitivity and water-blocking are caused by invasive fluids and are major causes of damage. Stress sensitivity caused by the alteration of effective stress, which equates to the overburden pressure minus formation pressure, is the other main damaging factor.

Once damaged, formation permeability can rarely be recovered.

Geological characteristics

Jurassic formations in Tarim oil field occur 4,534.5 to 4,968 m deep in high, steep structures. The Jurassic section includes tight sandstone and coal intervals. Main mineral types are quartz (46%), rock cuttings (46%), a bit of feldspar (6%), and mud minerals (7%).

Porosity is filled mainly with clay, calcium, and carbon substances. The clay minerals include illite, chlorite, and occasionally smectite and kaolinite.

Cores taken from the Jurassic target formation show that main types of porosity are dissolved pores between particles, some pores within particles, and microfractures.

The pressure coefficient of the target formation is 1.25 to 1.87; temperature is 120º C.; effective porosity ranges from 0.3% to 14.4% (average 5%); permeability ranges from 0.01 × 103 sq μm to 380 × 103 sq μm.

In short, the target formation can be distinguished as a low-permeability, high-temperature, high-pressure reservoir with microporosity.

Potential damage

We analyzed cores taken from the target formation in Well YN2 (depth 4,543.8 to 4,552 m).

The main types of potential damage are certain sensitivity to invasive fluids such as light flow rate sensitivity, salt sensitivity (critical level of mineral ions is 43,428 mg/l.), alkali sensitivity (critical pH value is 10), and midextent stress sensibility.

This study looks primarily at damage mechanisms and origins of water-blocking.

Water-blocking or filtrate-blocking is one of the most damaging mechanisms in low-permeability formations, especially in low-permeability gas reservoirs. When drops of invasive fluids move into small micropore throats, deformation will occur at the oil-liquid interface, and the extent of deformability is different in two ends (r1, r2 is curvature radius of two ends, respectively).

Capillary pressure ΔP is expressed with the following equation:7

∆ρ = 2σ (1/r11/r2)

Such additional resistance is the so-called “water-blocking effect” because of the stacking of water-blocking. While a string fluid drop coexists in a same capillary, flow resistance of oil or gas phase in target formation will greatly increase and permeability of the oil-gas phase remarkably decrease.

Generally speaking, water-blocking is notable when the diameter of formation pore throat is less than 10 μm.

The experimental results of pressing Hg in and out of core samples taken from the Jurassic target formation reveal that the diameters of pore throats in target formation range from 0.01 to 9.0 μm. Consequently water-blocking damage caused by capillary effect cannot be ignored.

Apart from some abnormal high-pressure spheres, the pressure coefficient of drilling fluids is larger than that of the target formation and can reach 1.90 g/cc. If there is insufficient shielding, packing, framing, and filling particles, large quantities of filtrate can invade the formation.

It can be seen from water-blocking damage experiments of low-permeability cores taken from the Jurassic target formation that the maximal damaging extent of permeability was 41.5% (Fig. 1). Along with reduction in core permeability, Ka, original water saturation, Swi, and increase in oil-water interfacial tension, σo-a, the damaging extent Rs of water-blocking shows an upward trend (Fig. 2).

Because of well depth, high pressures, and drilling interruptions, the drilling period and duration of time that drilling fluids were soaking into the formation were prolonged; hence the amount of invasive fluids increased. In particular, various kinds of macromolecule polymer treating agents were absorbed on the borehole wall and reduced the radii of micropore throats. This eventually resulted in relatively higher extent of damage to formations with low permeability and micropore throats.

Fluid study

Based on current drilling technology and known damage factors in Jurassic formations with low-permeability, guidelines to develop new drilling fluids include:

- Selecting effective surfactants to minimize filtration and water-blocking.

- Selecting compound temporary shielding or packing agents mixed with framing, filling, and deforming particles to form thinner and tighter mud cake on borehole wall. The formed mud cake should have a good toughness, high strength, and drainage rate to protect formation from stress damage and long-term exposure to drilling fluids.

- Optimizing various treating agents to avoid damage caused by macromolecule polymer agents pressed into formation along with drilling fluid filtrate.

It is also necessary to optimize fluids to prevent formation collapse by inhibiting sloughing and staying within a safe density window.

Selecting surfactants

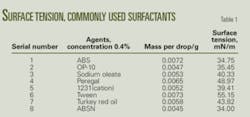

Lab experiments tested many surfactants commonly used to minimize surface tension (Table 1). These included:

- Alkyl benzene sulfonate (ABS).

- Alkyl phenol alkoxylate, nonionic (OP-10).

- Sodium oleate.

- Peregal (nonionic).

- 1231 (cation).

- Tween.

- Turkey red oil (sulfonated castor oil; anionic).

- ABSN.

Based on the low mass/drop, OP-10 and ABSN had the most efficient capacities to reduce surface tension (Table 1).

Temporary plugging

Temporary plugging agents in drilling fluids can quickly form thin, strong, tough mud cake that can prevent small particles and filtrate from deeply invading formations. Ideally, temporary plugging agents should be easy to drain out afterwards. High-quality drilling fluids with good temporary plugging characteristics can be designed by compounding framing and deforming particles, etc.

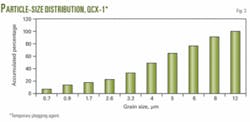

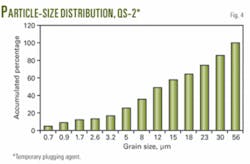

On the basis of size distribution of pore throats of target formation with low-permeability in Jurassic system and size distribution of present temporary plugging agent particles such as QCX-1, QS-2, etc. (Figs. 3-4).

After numerous experimental tests, we chose QCX-1 as the optimal plugging agent with compatible framing particles for Jurassic formations. To the QCX-1, we added deforming particles such as FB-2 (particle-size distribution of 0.04 to 75 μm; median particle size 12.0 μm), and asphalt base materials FT-1, AL, and YL-80 to reinforce effect of temporary shielding and plugging, and low filtration.

Rheology, inhibition, compatibility

Experiments with different formulations allow characterization of successful fluids by low-solid phase, nondispersed, sylvite sulfonated polymer. This contains 3% bentonite grouting + 0.2% KPAM + 4% SMP-1 + 2% DFD-140 + 4% SPNH + 0.4% LV-CMC + 6% KCl + 3% MHR-86D (lubrication) + 0.2% ABSN + 2%QCX-1 + 1.5% FB-2 + BaCO3.

The measured rheology parameters include:

- Density, 1.86 g/cc.

- Apparent viscosity, 55 mPa-sec (1 megaPascal-sec = 1 cP).

- Plastic viscosity, 38 mPa-sec.

- Dynamic shearing force, 17 Pa.

- Initial gel strength, 5 Pa.

- 10-mi gel strength, 15 Pa.

- API filtration, 4.5 ml.

- HTHP filtration, 8.0 ml.

- pH value, 9.0.

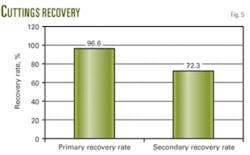

The experimental results show that rheological properties, filtration, and temporary plugging effect of the new fluids meet the requirements for use in the target formation. The primary and secondary recoveries of rock cuttings were 96.6% and 72.3%, respectively (Fig. 5). The new, low-permeability drilling fluids are good inhibitors and are compatible with formation rock. Also, mixing drilling fluid with in situ fluids in 1:1 proportion resulted in no obvious abnormal phenomena.

Permeability recovery

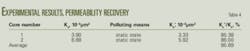

The test conditions of core samples included a confining pressure of 4 MPa and a flow rate of 1.0 ml/min. The initial permeability, KS, of core samples taken from the Jurassic target formation was measured by displacing with neutral kerosine.

Next, lab personnel reversely contaminated the cores with drilling fluids for 4 hr then removed them from the fluids, removed the mud cake, reversed core direction, displaced with neutral kerosine, measured permeability KS′ of contaminated cores, and calculated the permeability recovery Ks′/KS of contaminated cores.

Table 2 data show that the permeability recovery of cores contaminated with new, low-damage drilling fluids increased 27.2% (with added surfactant and temporary plugging agents).

New fluid effectiveness

The new KCl-sulfonated polymer drilling fluids were first field tested in the Jurassic section of preliminary prospecting well YN4 (depth 3,641 m) in Tarim oil field. Table 3 shows the rheological properties and permeability recovery of wellsite drilling fluids taken from well YN4.

We tested Core No. 1 (Table 4) with high-concentration agents such as KCl, FT-1, AL, FB-2, and YL-80 (able-deforming agents). The rheological properties and filtration performance were acceptable; API filtration was 1.0 ml, and HTHP filtration was 2.0 ml.

The formed mud cake was thin, dense, and tough, reflecting that particle-size distribution of various kinds of treating agents was reasonable, and relatively low filtration was good enough to protect the formation.

The second drilling fluid system (Table 3) was added to 2% QCX-1 + 3% FB-2 + 0.2% ABSN + 3% EP-553 (polybasic alcohol). The results show that viscosity and shearing force of the drilling fluids increased a bit, while the rest of the parameters changed little.

As shown in Table 4, permeability recovery (Ks′/KS) was more than 85%, indicating that the second drilling fluid can protect formation from damaging.

Field tests with the new, low-damage drilling fluids in Jurassic formations show that drilling trips were successful and drilling rates were quick, with low frictional resistance and no borehole instability.

Learnings

The new fluids were field tested in Well YN4 by Tarim Drilling team and the research team from China University of Petroleum, Beijing. Based on the results from laboratory evaluation experiments and these field tests, we draw the following conclusions:

- Water-blocking and stress sensibility are two main damaging types of low-permeability tight sandstone reservoir. Experimental results of target formation core samples show that the damaging extent of water-blocking could reach 41.5%.

- The main factors influencing water-blocking include permeability, porosity, initial water saturation (gap between irreducible water saturation and original water saturation), and oil-water interfacial tension. Other influencing factors include lithology, types of formation cement, pore structure, properties of invasive fluids, etc.

- The new, low-damage, broad spectrum KCl/sulfur polymer drilling and completion fluids appear to prevent water-blocking, are effective plugging agents, prevent collapse, and have high permeability recovery. The new fluid provided effective formation protection and stabilized the wellbores.

References

- Lin, Guang-rong, Shao, Chuang-guo, and Xu, Zheng-feng, “Fluid damage and solution method study of low permeability gas reservoir,” Journal Petroleum Exploration and Development, 2003, Vol. 30, No. 6, pp. 117-118.

- Ren, Xiao-juan, Zhang, Ning-sheng, and Zhang, Xi-feng, “Damage of residual water on permeability of tight gas reservoir,” Journal Natural Gas Industry, 2004, Vol. 24, No. 11, pp. 106-108.

- Bennion, D. Brant, Thomas, F.B., and Ma, T., “Formation Damage Processes Reducing Productivity of Low Permeability Gas Reservoirs,” SPE 60325, SPE Rocky Mountain Regional Low Permeability Reservoirs Symposium, Denver, Mar. 12-15, 2000.

- Erwom, M.D., Riersom, C.R., and Bennion, D.B., “Brine Inhibition Damage in the Colville River Field, Alaska,” SPE 84320, SPE Annual Technical Conference, Denver, Oct. 5-8, 2003.

- Bennion, D.B., Thomas, F.B., and Bietz, R.F., “Remediation of Water and Hydrocarbon Phase Trapping Problems in Low Permeability Gas Reservoirs,” Journal of Canadian Petroleum Technology, 1999, Vol. 38, No. 8, pp. 39-48.

- Zhang, Qian, Du, Jian-fen, and Cui, Li-chun, “Study on stress sensibility of the reservoir rock in Sulige gas oil field,” Journal Drilling Fluid and Completion Fluid, 2006, Vol. 23, No. 5, pp. 29-30.

- Cui, Ying-chun, and Zhang, Yan, “Characteristic of formation damage in low permeability reservoir,” Journal Drilling Fluid and Completion Fluid, 1998, Vol. 15, No. 2, pp. 11-13.

The authors

Yong Shu ([email protected]) is a senior engineer and PhD student at the MOE Key Laboratory of Petroleum Engineering in the Department of Oil & Gas Engineering, China University of Petroleum (Beijing). His current research interests include damage during drilling and production of low-permeability oil and gas fields. Shu holds a BS (1997) from China University of Petroleum (East China).

Jienian Yan ([email protected]) is a professor and PhD student supervisor at the MOE Key Laboratory of Petroleum Engineering in the Department of Oil & Gas Engineering, China University of Petroleum (Beijing). His research interests focus on drilling fluids, borehole stability, formation damage control, etc. Yan holds an MS (1981) from Southwest Petroleum University, Chengdu, China. He is a member of SPE.