A study of the natural fractures in BA oil field in Algeria’s Sahara Desert suggests horizontal and multilateral drilling may improve production.

BA oil field is characterized by considerable production potential. There are four Cambrian reservoir units. We focus on two lithological units (Unit 1, Unit 2) that show very low correlation coefficients between permeability and porosity. This coefficient is only 0.22 for reservoir Unit 1 and 0.19 for Unit 2.

Overall, the reservoir is highly fractured with an index of fluctuation between 1.75 and 0.2. The fractures are vertical and horizontal and classified as open, half-filled, or closed.

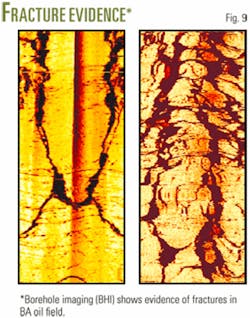

This evaluation of the fracture system is based on images from the ultra sonic borehole imager (UBI) and from the circumferential borehole imager logging (CBIL).

Despite the high intensity and type of existing fractures and large number of vertical wells drilled, oil production from the reservoir is relatively low.

Our results suggest that horizontal and multilateral drilling would improve production in the field. In certain conditions, horizontal wells can offer significant production improvement over vertical wells. In order to efficiently target areas of highest fracture density, we also believe that geosteering should be considered as an affordable and economic option.

Moreover, based on our evaluation of the in situ stress distribution, this article includes our suggestions for the most suitable well orientation to ensure well stability.

History

BA oil field was discovered in 1958 and the first borehole was BA-1. As the field was expanded, subsequent wells were consecutively numbered: BA-5, BA-6, etc.

Geologically, the field sits on an important structure in the Algerian Sahara. The reservoir has two main sandstones: Unit 1 and Unit 2.

Resulting mainly from diverse tectonic events, an integrated fracture study was initiated in order to forecast fracture flow potential with regard to the low permeability and porosity characterizing these units. The study was based mainly on openhole logs and borehole imaging. Additional data integrated core observation and regional structural and stress distribution.

First, based on the intensity and distribution of fractures, the field was expected to have higher production. The availability of different borehole petrophysical data, particularly fracture type, distribution, and orientation, provide a good opportunity to design different drilling configurations. Multilateral drilling using stacked and opposed wells seems to be the most efficient technique.

Second, application of multilateral drilling within this oil field will provide even better economical exploitation. In order to target both transversal and longitudinal fractures, the selected technique will constitute an alternative procedure prior to the existing vertical well drilling.

Using geosteering and logging while drilling (LWD), drillers will be able to maximize contact with the objectives, principally the longitudinal fractures.

Moreover, engineers need to determine the most appropriate well orientation in order to ensure well stability. Orientations suggested in this article are based on an in situ stress distribution study, an important input to the proposed well drilling program.

Geology, tectonics

The area has been affected by different tectonic events.1-3 Chronologically, these events coincided with the Pan-African phase; the Caledonian phase; and the Hercynian phase, which is divided in two movements:

- Visean phase (Hercynian minor phase). This phase is compressional, with a direction of N40°E and leading to creation of important structures and NW-SE-trending faults.

- Upper Carboniferous-Permian phase (Hercynian major). This phase has also been found compressional, with a direction of N120°E; it is believed to be one of the most important compressional phases affecting the area.1 2

The structure has also been affected by later tectonic events including a distensile Triassic-Liasic phase, Autrichian phase, and Tertiary phases.2 4 As is mentioned by the same listed authors, the impact of other tectonic events is not excluded.

Stratigraphy

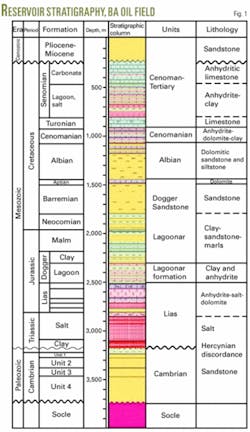

The lithologies in this field consist mainly of detrital sedimentary rocks with a Precambrian basement or socle (Fig. 1).5-7 The Cambrian age reservoir units include:

- Unit 1; of varying thickness from south to north. This unit consists of well-sorted, fine to medium grain sands; the rock is very compact.

- Unit 2; about 100 m thick. This unit is characterized by the presence of fining upward sequences. It’s also distinguished by a decrease of clay cement, compared to Unit 1. The grain size distribution is heterogeneous.

Detailed descriptions of both units as well as other, underlying units have been documented by many authors.2 6-8

Petrophysical characteristics

We mapped petrophysical data from the reservoir units. The data distribution shows diverse discrepancies between different boreholes. Notably:

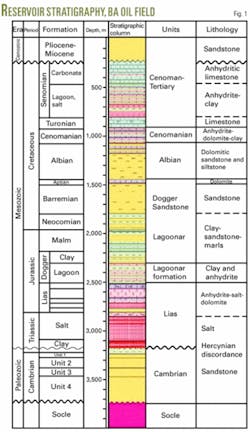

- Unit 1 is characterized by relatively very low porosity, 3.5-8.5 % (Fig. 2).

- Generally, porosity gradient increases towards the southeast and the northeast (Fig. 2).

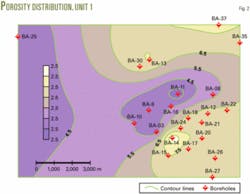

- The permeability of Unit 1 is low and varies from one borehole to another, with a maximum value of 2 md in BA-12 (Fig. 3).

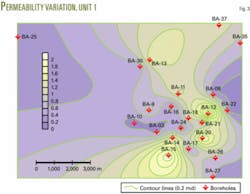

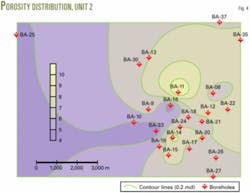

- Unit 2 is characterized by a maximum porosity of 10%. Unit 2 is also distinguished by a very low porosity distribution (Fig. 4).

- In Unit 2, we noticed that the porosity values improve (relatively) towards the eastern part of the field.

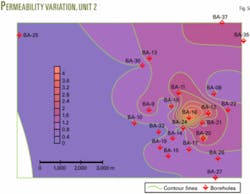

- Permeability values for Unit 2 are low (Fig. 5). The maximum values are seen near BA-1, BA-21, and BA-24.

null

null

null

null

Fractures

Natural fractures are one of the main targets in this study. Fractures were identified from borehole images, cores, and openhole logs.8

Natural fractures are caused by tectonic stresses (tension, compression, torsion) and diagenetic effects, such as those resulting from compaction. Scientists studying the fracture type, intensity, and orientation have determined that the fractures are the main influence on the reservoir quality.2 3 9

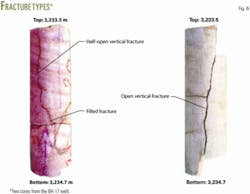

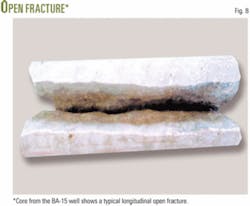

In BA oil field, natural fractures can be distinguished into three types: open fractures, half open, and sealed fractures (Figs. 6-9).

null

null

null

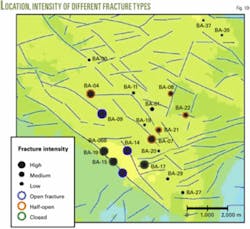

Transverse (horizontal) and longitudinal (vertical) fractures typically cross each other (Figs. 6-7). Their occurrence indicates their difference in chronology and different in situ stress distributions. Fig. 10 shows the fracture pattern and intensity.

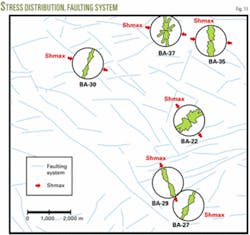

We have analyzed fractures in different cores from BA oil field. The fractures have different orientations, mainly similar to the major tectonic events affecting the studied area (N120E and N40E). Predominantly, they appear to be related to the directions of early and late Hercynian phase stresses.1 2 8 Fig. 11 illustrates the stress orientation approximately parallel to the faulting system.

Similar orientation between fractures and faulting system might be one of the better criterion that can be used to demonstrate that fractures found in this oil field are of tectonic origin rather than other sources.

Moreover, core descriptions from both reservoir units show that the lithology consists mainly of sandstones typically characterized by a low percentage of clay, rarely exceeding 15%. Fonta et al. determined statistically that sediments containing less than 30% clay (brittle material) are more exposed to tectonic fractures rather than diagenetic or other events.10 Similar cases have been studied in many other oil fields worldwide.11-15

Analyzing the fracture intensity allows a “quantification” of the fractures according to their fracture intensity index (FII).16 Results were as follows:

Based on this fracture intensity distribution, it appears that more than 40% of the boreholes encountered within BA oil field are characterized by highly fractured system.8

The parameters defined above represent basic guidelines. Applying these guidelines should be done on a zone-by-zone basis.

Stress distribution

Based on the relatively low permeability, we assume that the production from the two reservoir units is unconventional. Further development of the field should focus on the existing fractures, especially on the open and conductive fractures. These would have more influence on the flow circulation and therefore should contribute to improved productivity.

Because of the frequency of natural fractures in BA oil field and their importance, we assume that there are instabilities in the rock. Therefore, the in situ stress distribution should be taken in account prior to decisions on drilling procedures.

We analyzed the data to determine fracture orientations and in situ stresses in order to ensure borehole stability.

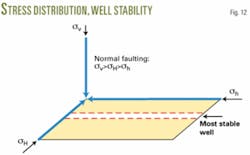

There are three principal stress vectors: one vertical, σ̣v, and two horizontal, σH and σh. These stresses are useful to designate the type of drilling and well orientation that should be used, such as horizontal drilling. Analyzing the in situ wellbore stresses is essential to identify the most stable well orientation. Generally, based on stress regime distribution, there are three different types of fractures possible:

- Normal faulting (extensional stress regime) corresponding to σ̣v >σH >σh

- Strike slip faulting (transpressional stress regime) leading to σH >σv >σh

- Reverse faulting (compressional stress regime) corresponding to σ̣H >σh >σv.

In the case of normal faulting, the most stable well orientation is perpendicular to the maximum horizontal stress, σH. In strike slip faulting, a vertical well is the most unstable well configuration. In the reverse faulting regime, the most stable well is parallel to maximum horizontal stress component, σ̣H.13 15 17-19

Consequently, we deduce that the most stable well orientation will be perpendicular to the area that has the smallest difference between two main stress components. Fig. 12 illustrates the most stable well orientation in the case of normal faulting. This figure corresponds to one of the main cases present in BA oil field.

Drilling procedure

In modern field management, it is necessary to assess every available recovery technique, including new drilling and well technologies. Using advanced drilling techniques may result in higher production. The use of deviated, horizontal, and multilateral wells, for instance, has become common worldwide.

Current drilling technology is moving towards maximum reservoir contact using extended-reach horizontal and multilateral wells. In some areas, extended-reach drilling can improve the well productivity by lowering the pressure drawdown; this minimizes operating costs and maximizes profitability. A general improvement in drilling and well technology has led to larger parts of the reservoirs being reachable with fewer wells (OGJ, July 10, 2000, p. 36).20-23

In addition, improved directional drilling tools including measurement and logging while drilling (MWD and LWD) have led to an increase in the number of long-range and advanced wells.

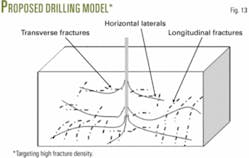

Horizontal and multilateral drilling allows the wellbore to intersect multiple longitudinal and transverse fractures (Fig. 13). This will probably help optimize reservoir performance. In BA field, where the normal faulting system corresponds to longitudinal fracture orientation, the applied well drilling orientation will be perpendicular to the maximum stress regime (σH) intersecting longitudinal fractures.

Moreover, the case study, is concerned with different parameters such as the presence of the high rate of opened and half opened fractures (Figs. 6 and 8) and the considerable sandstone thicknesses of the reservoir, reaching sometimes more than 30 m (Fig. 1). All these factors may be considered the main stimulators to focus on advanced drilling technology.

Based on field experience, the reservoir is sufficiently thick to steer the drilling. Fig. 13 illustrates a proposed drilling model with multilateral wells.

The use of geosteering may reduce the number of wells necessary. The main advantage of this method is that multiple fractures can be intersected with or without a long, horizontal section.

Learnings

Petrophysical properties of BA oil field have unconventional measured values. The presence of fractures is well proven by borehole imaging and core analysis. There are three types of fractures: sealed, half-open, and open. Open and half-open fractures are the predominant type found, both transverse and longitudinal with respect to the cores, and with different orientations.

The presence of fractures influences production, and optimum production should be higher. Vertical drilling does not exploit the fracture distribution as a main path for production enhancement. In order to target a great number of fractures (transverse and longitudinal), the authors recommend horizontal and multilateral drilling.

Reservoir development doesn’t necessarily require horizontal and multilateral wells, but it should take into account the in situ stresses. Development team should consider borehole stability in the reservoir. In addition, it is important to emphasize that geosteering would allow the team to steer the borehole into fractures at different orientations.

The importance of fractures in productive capability is known beyond these Algerian reservoirs; it is seen worldwide and confirmed by many case studies.

References

- Aliev, M., et al., “Geological Structures and Estimation of Oil and Gas in the Sahara in Algeria,” Altamira-Rotopress SA, Madrid, 1971, 265 pp.

- Boudjemaa, A., “Evolution Structural du Bassin Petrolier ‘’triassique’’ du Sahara Nord Oriental ( Algerie),“ These Sc., Universite Paris-Sud (Orsay), 1987, 240 pp.

- Klett, T.R., “Total Petroleum System of the Illizi Province, Algeria and Libya-Tanezzuft-Illizi,” US Geological Survey Bulletin 2202-A, Denver, 2000.

- Addoum, B., “l’Atlas Saharien Sud oriental: Cinematique des plis de chevauchements et reconstitution du bassin du Sud-Est Constantinois (Confins Algero-tunisiens),’’ These Sc., Universite Paris XI Orsay, 1995, 200 pp.

- Beuff, S., et al., “les gres du Paleozoique Inf Du Sahara,” Ed. Technip, Paris, 1971, 464 pp.

- Well Evaluation Conference, WEC, Schlumberger, Sonatrach, 1979.

- Benrabah, B., “Etude Sedimentologique des reservoirs Cambro-Ordovician du gisement d El Gassi,” Facultes des Sciences et des Techniques de l’Universite de Franche-Comte, Besancon, 1985.

- Marrakchi, Y., et al., “Etude de la Fracturation du Reservoir Cambro-Ordovicien du Champ d’el Gassi,” BSc. Report, University of Constaintine, Algeria, 2005.

- Benzagouta, M.S.,”Reservoir Heterogeneities in Fracturing Fluvial Reservoirs of the Buchan Oilfield (Northern North Sea),” Oil and Gas Science and Technology-Rev. IFP (French Institute for Petroleum). Vol. 56, No. 4, 2001, pp. 327-338.

- Fonta, O., et al., “The Fracture Characterization and Fracture Modeling of a Tight Carbonate Reservoir: The Najmah Sargelu of West Kuwait,” 14th SPE Middle East Oil & Gas Show and Conference, Bahrain, Mar. 12-15, 2005.

- Ozkaya, S.I., Lewndoswki, H.J., and Coskun, S.B., “Fracture Study of a Horizontal Well in a Tight Reservoir-Kuwait,” Journal of Petroleum Science and Engineering, 2006 (article in press).

- Al-Fawwaz, A., Hassani, S., and Nwabor, D., “Management of Geologic Risk, Uncertainty Defines Accurate Horizontal Well Placement,” World Oil, Vol. 227, No. 10, October 2006.

- Zillur Rahim, et al., “The role of Geomechanical Earth Modeling in the unconsildated pre-Khuff field completion design for Saudi Arabian Gas Wells,” Saudi ARAMCO Journal of Technology, Spring 2005, pp. 2-12.

- Al-Hawas, K., “Fracture Anisotropy Signatures in the Wudayhi Field Using Azimuth Seismic Data,” Saudi ARAMCO Journal of Technology, Spring 2005, pp. 24-37.

- Wolter, K.E., and Berners, H.P., “Bohrlochstabilitaet in Abhaengigkeit von den Gebirgsspannungsverhaeltnissen,” Erdoel Erdgas Kohle, 116, Vol. 10, 2000, Hamburg.

- Selley, Richard C., “Elements of Petroleum Geology,” W.H. Freeman & Co., NY, 1998.

- Hilgers, C., et al., “Paleo-Overpressure Formation and Dissipation in Reservoir Rocks,” Oil Gas European Magazine, Vol. 2, 2006, Hamburg.

- Soliman, M.Y., and Bonnen, P., “Rock Mechanics and Stimulation Aspects of Horizontal Wells,” Journal of Petroleum Science and Engineering, Vol. 25, 2000, pp. 187-204.

- Cunha, J.C., et al, “Planning Extended Reach Wells in Deep Water,” SPE International Petroleum Conference and Exhibition, Villahermosa, Feb. 10-12, 2002.

- Jahediesfanjani, H., and Civan, F., “Improving Performance of the Naturally Fractured Carbonate Reservoirs by Means of Various Stimulation and Completion Techniques,” SPE First International Oil Conference and Exhibition, Cancun, Aug. 31-Sept. 2, 2006.

- Garrouch, A.A., et al., “An Integrated Approach for Planning and Completion of Horizontal and Multilateral Wells,” Journal of Petroleum Science and Engineering, Vol. 44, 2004, pp. 283-301.

- Dossary, A.S., and Mahgoub, A.A., “Challenges and Achievements of Drilling Maximum Reservoir Contact (MRC) Wells in Shaybah Field,” SPE/IADC Middle East Technology Conference & Exhibition, Abu Dhabi, Oct. 20-23, 2003.

- Economides, Michael J., and Nolte, Kenneth G., “Reservoir Stimulation,” Third Edition, Wiley, NY, and Chichester, March 2000, 750 pp.

The authors

Mohammed S. Benzagouta ([email protected]) is an associate professor in the petroleum and natural gas engineering department of King Saud University, Riyadh. Previously he worked for the Algerian Oil Co. (Sonatrach), as well as the University of Constantine Algeria as associate professor. Benzagouta holds a Bsc from the Algerian Institute of Petroleum and a PhD from University of Newcastle upon Tyne, UK. He is a member of SPE.

Mohammed M. Amro ([email protected]) is an associate professor in the petroleum and natural gas engineering department of King Saud University, Riyadh. He joined that faculty in January 1999 as an assistant professor. Previously, he was on the staff at the University of Constantine, Algeria,worked at the German Petroleum Institute in Clausthal, and for Qatar Drilling Co. in Qatar. Amro holds a Bsc, an MS, and a PhD in petroleum engineering from Technical University of Clausthal, Germany. He is a member of SPE and the German Society for Petroleum and Coal Science & Technology, DGMK.