Site clearance and verification (SC&V) comprise the last stage of offshore decommissioning in which abandoned well and platform locations are cleared of all debris remaining from oil and gas activities. Net trawling uses a reinforced net assembly that is dragged along the ocean bottom to pick up debris.

This final of two articles on decommissioning oil and gas platforms in the US Gulf of Mexico presents descriptive statistics based on 308 net-trawling jobs performed between 2001 and 2005, updating previous analysis covering 1997-2001.1 (The first part appears in OGJ, Dec. 3, 2007, p. 44.) We summarize costs relative to structure type and water-depth categories and discuss factors that impact the cost of SC&V operations.

Federal regulations

In the US, federal regulations require that all wells and offshore structures in the Outer Continental Shelf be completely removed to a depth 15 ft (5 m) below the seafloor within 1 year after production on the lease ceases. After wells are plugged and abandoned and the structure is removed, regulations require that the site be cleared and verified “clear” by an independent third party.

A variety of techniques may be used to perform SC&V operations, but net trawling and diver survey are the most common in the Gulf of Mexico.

In diver salvage, divers identify targets and attach lift lines to the debris, and a crane on a surface support vessel lifts the debris from the water bottom and places it on deck for subsequent disposal on land.

Net trawling uses conventional trawling techniques with a reinforced net assembly to pick up debris. Net-trawling operations offer advantages in analysis relative to diver surveys because net trawling focuses exclusively on clearance and verification and the data are transparent and easy to interpret. Diving spreads typically perform many different services throughout decommissioning, and it is usually not possible to isolate clearance services from other activities, such as structure preparation, pipeline cutting, dredging, and others.

In 1981, the US Minerals Management Service introduced site-clearance regulations for the Gulf of Mexico Region. Current gulf OCS site-clearance activities are performed in accordance with the MMS GOM Region Notice to Lessees 92-02.

According to MMS regulations, all abandoned well and platform locations in water depths less than 300 ft (91 m) must be cleared of all obstructions present as a result of oil and gas activities.2 Clearance requirements are specified according to well and structure type:

- Temporarily abandoned wells; working radius centered on the well.

- Delineation or exploratory wells drilled with a mobile offshore drilling unit; 300-ft (91-m) radius circle centered on the well.

- Single-well caissons and well protectors; 600-ft (183-m) radius centered on the well.

- Platforms; 1,320-ft (402-m) radius centered on the geometric center of the facility.

For temporarily abandoned wells, the operator must protect the apparatus with a net guard. To establish the effectiveness of the guard, standard shrimp-trawling nets are pulled over the device to ensure 100% coverage. For a delineation or exploratory well, clearance can be verified with a trawl or a 500-khz sonar search scan.

The MMS-preferred clearance-verification technique for structures is to drag a standard trawl net across 100% of the site in two directions with each pass 80 ft (24 m) apart. According to federal regulations, trawls should be picked up after 30-min drag time and all shrimp caught in the trawl released. In water depth greater than 300 ft (91 m), sonar scanning is permitted.

At the conclusion of clearance operations, a completion report must be submitted to the MMS detailing the removal operation and activities on each line and certifying that the site has been cleared.

Factors

The time and cost to clear a site and verify clearance depend on a number of factors that are uncertain and unobservable, including the amount, size, and type of debris present; site location; equipment available to perform the operation; supply-demand conditions for labor and service vessels; clearance and verification techniques used; and weather conditions at the time of the operation.

A site may require different salvage techniques or a combination of techniques to remove debris. Each site is unique, and operators make decisions on which technique to employ based on their experience and knowledge of the site conditions.

• Structure type. The structure type that previously occupied the site determines the area that must be trawled for clearance and verification. Federal regulations require clearance operations centered on the well or the geometric center of the facility, with radius determined by the well or structure type: temporarily abandoned wells (working radius), delineation and exploration wells (300-ft radius), single-well caissons and well protectors (600-ft radius), and platforms (1,320-ft radius).

• Structure complexity. Offshore structures perform a wide variety of functions, depending upon the field development requirements, and are constructed according to various tiers of complexity.

A structure that is unmanned and serves in an auxiliary rolea compression station, meter facility, or storage site, for exampleis less complex than a manned drilling and production platform. Complex structures, especially development and manned production facilities, are likely to have more debris at the work site compared with unmanned facilities, caissons, and exploratory or delineation wells.

• Clearance, verification. Clearance may be performed with diver surveys, sweep assemblies, and heavy-duty trawl nets, electromagnetic and grappling devices, dredging buckets, or a combination of techniques.3 4 Diver salvage and net trawling are the most common approaches in the Gulf of Mexico.

Clearance may be initiated with a survey to determine where debris are located, or net trawling may commence without performance of an initial survey, depending on operator preferences and conditions (expected or known) at the site.

If divers were previously deployed to clear the site or if the structure is a caisson or delineation or exploratory well, SC&V will usually be performed with a shrimper net. If preclearance operations were not performed or if the structure is a production or manned platform, clearance with a heavy-duty net typically precedes verification with a shrimper net.

Operations are performed sequentially and only for the verification survey does the area trawled have to cover 100% of the site.

• Age. A steel structure in salt water will deteriorate from corrosion and wear, depending on the type and quantity of steel used, environmental conditions at the site, application of sacrificial anodes, and the manner in which hurricanes “use up” the fatigue life of the structure. Old structures have more time to gather and collect debris, and typically more targets will be identified and removed as a structure ages.

• Location. The location of the job where SC&V occurs influences the mobilization and demobilization times for arrival at the site. Most infrastructure in the gulf takes at most 12 hr to reach location; net trawling can begin almost immediately.

For most operations, distance from shore does not strongly influence costs. The distinction between near-shore and far-offshore activities can be significant, however, because the uncertainties associated with offshore operations are generally larger and of greater significance the farther offshore the activity occurs.

• Water depth. Water depth is often a primary variable in offshore construction activities because increasing water depth requires the size of the vessel to increase, reducing operational flexibility and increasing the cost of the operation. For net-trawling operations in water depths up to 300 ft (91 m), however, the vessels employed are relatively homogenous in terms of technical specifications.

Water depth does contribute to the time to set and retrieve netting and may be important if a given depth threshold is exceeded; water depth greater than 300 ft (91 m), for example, might necessitate use of remotely operated vehicles or manned submersibles to remove debris.

• Exogenous conditions. Weather conditions, mechanical problems, and trawler damage can affect the scope of SC&V operations and in most instances are unpredictable. Weather is a factor in all offshore operations, with extreme weather adversely affecting labor productivity and increasing downtime. Mechanical problems can be mitigated to some extent through preparation and proper contingency planning.

• Strategic decisions. Operators decide how a site is to be cleared, based upon experience and previous success of various techniques, technical information, equipment availability, and other factors. Cost is usually a primary consideration in decision making because operators want to fulfill the regulatory requirement in the most cost-effective and efficient manner.

Service contracts; statistics

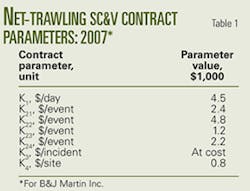

Net-trawling service contracts are typically written on a time and material basis with respect to the following elements: equipment and personnel ($/day), loss and damage ($/event), incidental ($/incident), and document preparation ($/site).

The equipment and personnel day rate covers the cost of the equipment and personnel to perform the service and includes the mobilization and demobilization cost to and from the dock site; all personnel, equipment, and supplies such as fuel, nets, lubrication, food, water, and navigation; and trawling services performed at the site.

A trawling vessel usually requires a four- or five-man crew for operation: a licensed captain, a surveyor, and two or three deckhands. The daily rate typically provides for 12 hr/day of trawling.

Nets gather and collect all sorts of debris during clearance operations and in the process may be lost or damaged. A separate loss and damage charge is expensed, depending on the type of net and if the damage is reparable.

Two types of nets are commonly used: standard shrimper nets and heavy-duty “Gorilla” nets. Nets are priced according to the cost of repair or if lost or irreparable.

Separate contract components cover boards, dummy doors, cables, chains, and buoys that are lost or damaged at the variable rate per incident. The company renting the vessel must arrange for disposal of trash collected from the operation. Document preparation and a closeout report on the trawling operation to MMS NTL 98-26 specifications are charged at a flat rate of per site.

Job specification is defined by the characteristics of the well per structure that occupied the site and the type of service requested by the operator. Although each job is characterized by a number of factors, only a few variables are usually recorded, such as the structure type caisson (C), well protector (WP), platform (P)), age (AGE) upon removal, and water depth (WD) at the site.

The total cost of job J, TC(J), is described in terms of the contract parameters as shown in the accompanying box.

• Data source. Data for 308 jobs performed by B&J Martin Inc. between 2001-2005 comprise the sample set. Jobs classified as “partially” completed or “incomplete” and those operations in state waters were excluded from analysis. To maintain the confidentiality of the data, operator identity is not revealed and only aggregate statistics are presented.

Total cost of each job was based on the price sheet for the year in which the job was performed. Price sheets describe the daily rate, loss and damage expense, meals and bunks, and report and track plot costs (Table 1). Reported job data included TD, GR, GU, SR, and SU.

Because the value of M was not reported, the cost excludes the expense of loss and damage or diver expense associated with lost boards, cables, chains, damage to rigging, or other exceptional events. Total cost also excludes the cost to dispose of trash. Daily rates start and end at dockside and standby rates at a lower basis apply to conditions as repair to outriggers or towing blocks caused by hang-ups.

Cost was estimated based on total number of days to perform the operation, number of reparable and irreparable nets, and the number of reparable and irreparable Gorilla nets. The job statistics were multiplied by the appropriate unit cost factors and summed, and the fixed cost of the track report was added. Costs are reported as current (nominal) dollars and are not adjusted for inflation.

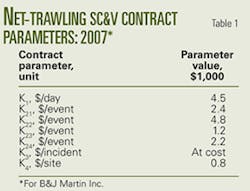

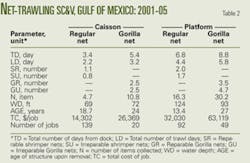

• Operational statistics. The total number of days to perform SC&V services for platforms is roughly twice the number of days for caissons (Table 2). This result is partially explained by the greater amount of area required to be trawled for platform sites.

For all other things equal (site location, age, amount of debris present, water depth, for example), if the time to perform SC&V is determined entirely by structure type, we would expect that the time to perform SC&V on a platform would be about five times greater than a caisson because the trawling area for a platform exceeds the area for a caisson by a factor of about five.

All other things are usually not equal, however, and because many other factors play a role in the cost of the service a significant attenuation of the theoretical value results.

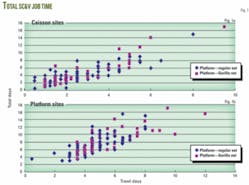

A trawling vessel normally operates for 12 hr/day; so the total number of days from dockside should exceed the total number of trawl days (LD) by a factor of about two. The impact of mobilization and demobilization to and from the site and variations due to the debris collected, weather conditions, time of year in which the operation is performed, again forces departure from this value. The ratio TD/LD ranges between 1.5-1.7 for the sample set (Table 2). Plots of TD vs. LD for caisson and platform jobs illustrate the data spread (Fig. 1).

The number of nets damaged when trawling across former platform sites is greater than caisson sites by a factor of about two (Table 2). Items collected provide some indication of the complexity of the task. Because the size, weight, and volume of the debris are not describeda tire and a 12-ft (4 m) long drillstring each counts as one item, for examplethis statistic does not provide a useful descriptor variable.

For the most part, the average number of items collected as a function of structure type behaves as one would expect with old, complex, manned platforms often yielding the most debris.

Gorilla nets are often applied at old platforms. For the sample set, about 35% of platform jobs employed Gorilla nets, compared to less than 10% at caissons. It is unlikely that caissons will have debris that would necessitate use of Gorilla nets, while for platformsdepending on the age, function, and previous clearance activitiesGorilla nets are more commonly applied.

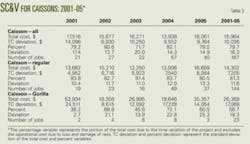

• Total cost. Tables 3 and 4 tabulate total cost of SC&V operations for caissons and platforms, according to jobs that employ only regular nets, jobs that apply Gorilla nets, and all jobs (regular and Gorilla net applications). The standard deviation of the total cost (TC Deviation) indicates the dispersion of the data.

The variable Percent reports the percentage of total cost arising from the day rate, which provides an indirect indication of the relative difficulty of the operation, because for difficult jobs the non time-varying cost of loss and damage will play a larger role in the total cost. The variable Deviation indicates the dispersion of the Percent variable.

The average cost to clear and verify a site previously occupied by a caisson is computed to be $15,964 (Table 3). Total cost varies across time and depends on the type of net used, with average costs ranging from $14,302 (regular nets) to $26,369 (Gorilla nets).

The value of the standard deviation is often one-half or more the average value, indicating significant variability across jobs. For platform sites, the average SC&V cost based on 141 jobs is $42,834 (Table 4). Net type is a key determinant of cost, with average cost ranging from $32,036 (regular nets) to $63,119 (Gorilla nets).

Personnel and vessel costs constitute the majority of the service cost for regular trawling. The average service cost for regular trawling exceeded 80% for both caissons and platforms, while for Gorilla net trawling, loss and damage play a more significant role and the day-rate percentage varied more widely, 36-72% for caissons to 46-59% for platforms. The cost of consumables (loss and damage) for Gorilla net jobs represents a significant part of the total cost reflecting more demanding trawling conditions.

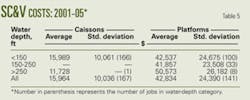

• Water-depth categorization. Table 5 shows average clearance and verification costs aggregated according to water depth. Only a few jobs in the sample set were performed in water deeper than 250 ft (76 m); so cost entries for this category are more uncertain. A significant cost difference exists between caissons and platforms, but across water depth, the cost is reasonably uniform across both structure types.

References

- Kaiser, M.J., Pulsipher, A.G., and Martin, J., “Cost of site clearance and verification operations in the Gulf of Mexico,” ASCE Journal of Construction Engineering and Management, January 2005, pp. 116-126.

- Department of Interior, Minerals Management Service, 30 CFR Parts 250, Oil and Gas and Sulphur Operations in the Outer Continental Shelf-Decommissioning Activities, US Federal Register, Vol. 65 (No. 131), 2000; pp. 41892-41903.

- Pulsipher, A.G., ed. Proceedings of International Workshop on Offshore Lease Abandonment and Platform Disposal: Technology, Regulation, and Environmental Effects, New Orleans, Apr. 15-17, 1996.

- Manago, F., and Williamson, B., eds. Proceedings: Public Workshop, Decommissioning and Removal of Oil and Gas Facilities Offshore California: Recent Experiences and Future Deepwater Challenges, Ventura, Calf., Sept. 23-25, 1997; US Department of the Interior, Minerals Management Service, OCS Report 98-0023.

The authors

Jimmie Martin Sr. has been involved in the oil and gas industry for 30 years as an owner and operator of offshore supply vessels. He was instrumental in implementation of site clearance legislation and invented the Gorilla net.

(Part 1 of this two-part series presents a biographical sketch for Mark J. Kaiser.)