Designing contingency measures for potential accidents is particularly important in remote environments.

This article discusses Shell’s oil spill response planning for exploration in the Alaskan Beaufort Sea, focusing on how the company will protect the Arctic environment. With carefully planned operations, properly equipped vessels, redundant equipment sets, and numerous other safeguards, Shell is prepared to handle any potential spill.

More than 140 wells have been drilled in the Canadian and US Beaufort and Chukchi Seas, with no well blow-outs. The US incident command system (ICS) for emergency management organizes spill plans according to a tiered response system, progressing from Tier 1 (small, locally significant), Tier 2 (medium, regionally significant), to Tier 3 (large, nationally significant). This article focuses on strategies that can quickly remove large volumes of oil if ice precludes an effective Tier 3 worst-case discharge response based solely on mechanical recovery systems.

The scope of this discussion includes technical, planning, and operational considerations for implementing specific offshore recovery and removal strategies in which ice dictates the appropriate choice of spill-response tactics.

Many important response topics are more fully described in Shell’s regional exploration oil-discharge prevention and contingency plan, submitted to the US Dept. of Energy’s Minerals Management Service in January 2007. That document includes details of community and agency notification, environmental impact assessment, wildlife rescue and rehabilitation, shoreline protection, communications, reporting, and spill-management systems.

Shell’s offshore drilling program involves two floating drilling systems (OGJ, Oct. 1, 2007, p. 40) supported by nine vessels (including four polar icebreakers). The support vessels carry fuel and supplies, transport personnel and equipment, provide anchor-handling, ice management, and oil spill response services, including the ability to store recovered products.

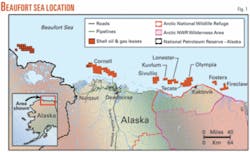

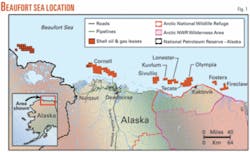

The plans include offshore activities over 4 months, July-October, in water about 100 ft deep, about 15 miles offshore (Fig. 1). The drilling program is planned to begin after the nearshore fast ice has broken up and drilling will proceed in predominantly open water conditions from early August on. Because of the possibility of ice incursions during the open water period, however, and the natural variability of the timing and duration of freeze-up, Shell’s oil spill response strategies and tactics are designed to cover a wide range of open water and ice conditions (Fig. 2).

Planning, resources

Based on previous exploration programs in the Chukchi and Beaufort Sea regions, Shell has the experience to drill in extreme arctic conditions. Shell’s goals are to prevent oil spills, protect the environment, and work with local communities to understand and preserve their cultural needs. Proper planning, selecting advanced ice-capable vessels and equipment, continually training on location, and relying on local knowledge help create a reliable oil spill prevention and control program for the Beaufort Sea.

Steps taken by Shell include:

- Developing a comprehensive Beaufort Sea regional exploration oil-discharge prevention and contingency plan reviewed and approved by state and federal agencies.

- Developing a critical operations and curtailment plan specifying strict procedures to monitor weather and hazardous ice conditions.

- Chartering capable vessels and equipment that can be activated immediately and could operate for extended periods in open water and broken ice conditions, to mechanically contain and recover spilled oil or eliminate oil using controlled burning.

- Conducting studies and ongoing field surveys of the marine operating environment (ice, weather, and sea conditions) in the Beaufort Sea.

- Preparing a comprehensive assessment and continually reevaluating countermeasures (mechanical removal, burning, dispersant application, and tracking) for their appropriateness and reliability in extremely cold climates.

- Identifying specific response strategies and developing tactics that could be implemented safely and effectively in a broad range of conditions including: drifting ice floes at breakup, open water, summer ice incursions, and new ice at freeze-up.

Operating environment

Shell and its response contractors are aware that traditional containment and recovery operations, while most effective during the open water period, may be interrupted by ice at the end of breakup (early August), during summer ice pack incursions, and during early freeze-up (late October).

Late in the drilling season, marine operators face additional difficulties imposed by increasingly low temperatures and rapidly diminishing daylight.

Shell’s team selected response tactics while aware of the constraints imposed by the unpredictable and dynamic environmental conditions. The company has examined and prepared for various wind and sea conditions, types and amount of ice, reduced visibility, and other conditions that influence selection of appropriate oil-spill response countermeasures.

Response strategies

Shell’s offshore and nearshore spill response plans include keeping dedicated personnel and equipment in constant readiness. The staff is drawn from Alaska Clean Seas (ACS), ASRC Energy Services Response Operations LLC, consultants, and Shell personnel, supported by an ice-capable marine fleet supplied by Edison Chouest Offshore LLC and Crowley Maritime Corp. (Fig. 3).

Response systems are maintained ready for immediate deployment with trained personnel from vessels and barges on site and close to the drilling rigs. The ice-strengthened vessels and barges carry high-volume-throughput skimming systems that can recover oil and emulsions at rates that are several times the worst-case discharge planning standards required by federal and state regulations.

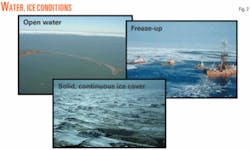

Two large skimming vessels, each with two Lamor 5-brush skimmers, permit several ways to use these systems downstream of a blowout. One configuration involves recovery of oil downstream of an open-apex, oil-deflection system with one oil-spill response vessel, while the other vessel moves to a backup storage tanker to unload its recovered oil emulsion (Fig. 4).

The presence of cold water and ice can actually enhance response effectiveness by limiting oil spreading and slowing the weathering processes that can make oil more difficult to recover or burn. By working with the natural environment as much as possible (e.g., allowing oil to be contained by ice), responders can often increase the response window-of-opportunity and improve the effectiveness of mechanical recovery and in situ burning techniques.

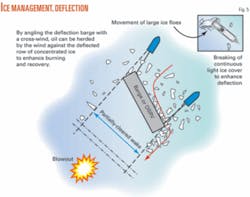

Deliberate ice management (breaking large floes and moving or deflecting ice) can be used in some situations to extend the operating window for booms and skimmers (Fig. 5). The goal is to have access to a range of response options that provide the greatest flexibility in being able to deal with rapidly changing offshore environments.

As ice concentrations progress from open drift to heavier pack ice conditions, mechanical recovery systems experience progressively lower oil encounter rates (are less effective) because crews must shift from large open-apex boom configurations to individual, over-the-side skimmers. Operating with smaller, more maneuverable skimmers, responders can reach pockets of oil trapped against or between ice cakes and floes or in leads. These pockets of oil may also be accessible with over-the-side skimmers deployed from the larger response vessels.

As the effectiveness of mechanical recovery declines in expanding ice coverage, Shell would work closely with the unified command and the Alaska regional response team to assess continually the potential for controlled burning. Once authorized, Shell would refocus the primary response effort toward burning the oil contained naturally by the ice. Ignition during such operations normally involves use of a helitorch, an aerial ignition device hung from a helicopter, to set fire to the oil safely and reliably.

Combustion may also play an important immediate role for safety reasons in the unlikely case of a blowout. Because of the potential for large quantities of natural gas and vapors from the surfacing oil directly over the blowout, it is likely that a decision would be made to ignite the gas as soon as the drilling rig moves off location. This action would eliminate the risk of a dangerous accidental ignition when vessels are close to the blowout, and under certain conditions the burning of the gas cloud could eliminate a significant percentage of the surfacing oil as well.

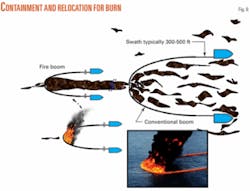

Because of the importance of controlled burning as a rapid and effective means of eliminating large volumes of oil quickly with and without ice, Shell has purchased and trained with state-of-the-art equipment (i.e., fire boom, helitorches, hand-held igniters, etc.) for the burning of oil in place under a wide range of environmental conditions (Fig. 6).

If the oil is properly contained (by fire booms or ice), burning even relatively thin layers only a few millimeters thick can be 50-70% efficient. Thicker oil layers commonly achieved in booms or wind-herded against ice or a shoreline can easily support removal efficiencies exceeding 90%. With burns potentially eliminating about 1,000 bbl oil/hr over a burn area only 100 ft diameter, the combustion of oil holds promise for a spill source that has a fixed location, is relatively localized on the sea surface, and consists of highly flammable, fresh oil.

The burn strategies described in Shell’s oil spill contingency plan include realistic assessments of the constraints in burning of oil on water. For example, many oils that are emulsified beyond 25% (water-in-oil) are difficult to ignite; and, should winds exceed about 20 knots, it may also be difficult to burn. All burning must be approved and carried out according to key safety issues, including avoiding other flammable slicks close to the controlled burn, completing all burning safely away from any vessels or facilities, and planning the burn so that the products of combustion (primarily the visible smoke plume) do not impact communities and other sensitive resources downwind.

The controlled, in situ burning of oil, especially during extreme operating conditions that could reduce the efficiency or the safety associated with physical removal techniques, often provides a highly effective alternative response option. Controlled burning, especially in cold climates (with or without ice present) is a proven method to eliminate large quantities of oil with minimal logistics and without the need to store massive quantities of recovered oil.

By working closely with regulatory agencies and carefully monitoring the trajectory of the smoke, Shell can ensure oil is burned with minimal environmental impact. Oil burns can be limited to sites that are a safe distance, generally 3 or more miles downwind of people and carried out in full compliance with federal and state guidelines.

Shell also recognizes the potential for dispersant application in certain environments where wind and sea conditions may preclude or seriously reduce the safe and effective use of booms and skimmers. This involves use of fixed-wing aircraft or helicopters to apply chemical dispersants. There are also times when dispersant use might be considered to enhance elimination of oil that has escaped mechanical cleanup and controlled burning operations.

While the use of chemical dispersants is not proposed in Shell’s current oil spill contingency plan, it is clear that progress is being made to understand better the full potential for dispersant use even in very cold climates. With sufficient mixing energy and water depth for safe and effective dispersion, there could be situations in which the net environmental benefits for dispersant use far outweigh any potential negative impacts.

For this reason, Shell has arranged for personnel and equipment to be available on short notice following any major spill just in case there is a request by the unified command to consider dispersant use.

Key planning

Shell, together with its highly trained primary response contractors, ASRC Energy Services (AES) response operations and Alaska Clean Seas (ACS), has developed a comprehensive oil-spill response program for its Arctic exploration program in the Alaskan Beaufort Sea.

In the remote event of a major spill, Shell’s response team will be ready, on location, to recover and eliminate as much oil as possible, and to minimize environmental impacts.

Shell’s conventional open-water containment and recovery systems are capable of dealing with discharge volumes more than four times greater than the federally or state mandated worst-case discharge in open water (less than 10% ice concentration) and potentially at a reduced capacity over a range of open drift conditions (10-60% ice concentration, depending on the ice distribution and floe size). In a typical year, these conventional systems apply through most of the drilling season from early August to mid-October or later. In more severe ice concentrations (drifting floes at breakup, heavy ice incursions in summer and new ice at freeze-up), the effectiveness of mechanical recovery systems (with or without booms) drops sharply enough that response strategies need to include burning of oil to achieve high oil removal rates.

Controlled burning is a proven arctic response strategy developed in more than 30 years of experience incorporating extensive lab and tank testing, large-scale field trials, and actual incidents. Established guidelines are in place to allow in situ burning to take place with scientifically monitored safeguards to protect responders, the environment, and local populations.

The physical characteristics associated with Shell’s worst-case spill scenario (i.e., the nature of the release and environmental conditions) support the choice of burning as an effective response option in any significant ice cover. Key considerations in support of this position include:

- The fresh nature of oil released to the surface.

- Limited oil spreading due to reduced temperatures.

- Slower weathering rates related to thicker films and lower wave energy.

- A high potential for effective oil containment with ice in any close pack condition.

- Moderate sea states commonly associated with any significant ice cover.

At an operational level, by having vessels and critical resources at or near the drilling locations, responders are able to access the oil quickly and implement the most appropriate response strategy according to conditions at the time. The availability of four highly capable support icebreakers, including the latest generation of vessels with azimuthing (rotating) drives, provides an opportunity to effectively to manage the ice for spill response through such measures as ice deflection, flushing trapped oil from beneath small floes, and breaking down large floes to expose oil for burning or recovery.

Important issues and uncertainties affecting the success of a spill response in ice involve the unpredictable and dynamic nature of the offshore environment and challenges of operating late in the season with freezing temperatures and darkness.

Fortunately, at that time the ice acts as an effective containment mechanism, minimizing the contaminated area and maintaining thick oil films for burning through aerial ignition (reducing the exposure of responders on the surface to extreme conditions). In the case of a late-season incident, proven techniques are available to track oiled ice for extended periods and to take advantage of opportunities to access the oil with helicopter-transported crews as the ice develops.

The authors

Alan A. Allen ([email protected]) is principal at Spiltec, Woodinville, Wash., since 1982, and has spent 25 years developing in situ burn and dispersant application techniques and equipment. He has more than 38 years’ experience as a technical advisor and field supervisor involving hundreds of oil spills around the world, including general manager of Alaska Clean Seas (formerly ABSORB), Prudhoe Bay (1979-82); general manager of Crowley Environmental Services Corp., Anchorage (1977-79); manager of Dames & Moore Consulting, Santa Barbara, Calif. (1973-77); director of MARCONSULT Inc. Environmental Services Dept., Santa Monica, Calif. (1971-73); and scientist at General Research Corp., Santa Barbara (1965-71). Allen served in the US Navy, 1961-65, holds a BA from Washington & Jefferson College, Washington, Pa., and has completed graduate studies in arctic engineering, oceanography, physics, and math at the universities of Maryland, California, and Alaska.

David F. Dickins ([email protected]) is principal at DF Dickens Assoc. Ltd., La Jolla, Calif. He has managed his own consulting practice specializing in Arctic environmental studies since 1978. Dickins obtained a BASc in mechanical engineering (1971) at the University of British Columbia. He is a registered professional engineer with the Association of Professional Engineers and Geoscientists of BC.

Susan M. Moore ([email protected]) is Alaska operations manager for Shell E&P Americas, Anchorage, responsible for implementing the spill-response operations and workforce development. She joined Shell in 1992 as a facilities engineer for the shelf division of the Gulf of Mexico. For 2 years, she led the team preparing the Ursa tension leg platform facilities, then worked on the Nigeria Bonga FPSO, 1998-2002, followed by other projects in Nigeria, Brazil, and Shell’s Malikai project in Malaysia, 2004-07. Moore earned a BS in civil engineering (1992) from South Dakota School of Mines and Technology and is a registered professional engineer and project management professional. She represents Shell on the operations review team for Alaska Clean Seas.