Custom-built rig uses reverse-circulation pipe to drill basalt

EnCana Corp. had a new rig built for reverse-circulation airlift drilling to prevent lost-circulation through thick, fractured, vuggy basalts. Encana was faced with drilling Miocene basalt sections as thick as 11,000 ft, overlying prospective sedimentary sections in three wells in south-central Washington State’s Columbia River basin. The wells are operated by Denver-based Encana Oil & Gas (USA) Inc. but are being financed 100% by Shell. Denver-based Delta Petroleum Corp. has a 3.75% working interest.

The new drilling rig was built by Boart Longyear’s Lang Exploratory Division, in the company’s Salt Lake City yard. Boart Longyear, a member of the National Drilling Association, is a subsidiary of Advent International.

Reverse circulation

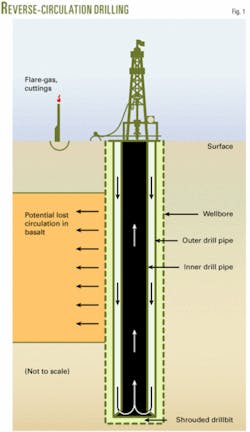

In conventional rotary drilling, drilling fluids or gases are pumped down the drill pipe, out through the drillbit, and return to the surface carrying drill cuttings in the annulus between drill pipe and wellbore.

Reverse-circulation drilling uses a special “pipe-in-pipe” coaxial drillstring. Fluids are pumped down the annulus between the inner and outer walls of the drill pipe and return to surface through the inner pipe (Fig. 1).

Reverse-circulation (RC) drill pipe is dual wall; the inner pipe string is suspended within the outer pipe string. Joints are made up conventionally and the inner string is sealed when the outer barrels are threaded together. RC pipe can be used with rotary bits or air hammers.

Compressed air is pumped after the drilling fluid, creating a dual-gradient fluid system. Perforations in the inner pipe allow the pressurized air to escape from the annulus and flow back up the inner pipe, creating a vacuum that helps to lift the cuttings.

Drilling fluids remain inside the RC drill pipe and cannot escape into the formations.

The drillstring used by Encana with the Lang rig is 6 5/8-in. diameter external upset outer pipe with a 4-in. diameter inner tube that is supported inside the outer pipe by a series of spiders.1

New rig

EnCana’s Gary Houghton said that his company chose Lang for its experience working in basalts.2

The custom-built LM700 cost about $4 million and uses reverse-circulation airlift to get through the hard basalts interspersed with lost-circulation zones.

The derrick has a 700,000-lb hookload capacity, includes a top drive, and sits on a 23-ft high substructure. The mast can accommodate 100-ft stands of pipe and can hold as much as 12,000 ft of 6 5/8-in. diameter dual-wall pipe or up to 16,000 ft of conventional pipe (Fig. 2).

The drilling system includes a 30,000-gal fluid system, two 900-cfm compressors, 1,400-psi booster, and a 65-ton Link Belt crane.1

On the first hole, the Lang rig drilled about 120 ft/day, more than double the previous rate of 52 ft/day.1

Three wells

EnCana has the largest acreage position in the Columbia River basin, about 811,000 net acres. It used the LM700 rig to drill the basalt sections in three 14,000-ft wells in Grant and Yakima counties, Wash.:

- EnCana Anderville Farms Inc. 1-6, in the Saddle Mountains, about 7 miles east of Mattawa.

- EnCana Anderson 11-5, about 8 miles north of Sunnyside (Fig. 3).

- EnCana Brown 7-24.

The drilling plans involved using the Lang rig for RC drilling through the basalt sections, followed by a conventional rotary rig (DHS Drilling Co. Rig 7) for the underlying sedimentary sections (Fig. 4). Bill Delahoussaye is the on site drilling supervisor for EnCana Oil & Gas Inc.

The first well, Anderville Farms 1-6, was initially spudded in December 2004 with a truck-mounted Lang rig using a reverse-circulation system but was not able to complete the drilling, which prompted construction of the new LM700 rig.

The LM700 rig reentered the hole in September 2005 and drilled to 7,800 ft. The sedimentary section was drilled by a second rig to about 14,500 ft, completed in August 2006.

EnCana spudded the second well, Anderson 11-51 in hilly terrain August 2006, and the Lang rig was to drill to about 11,000 ft. By early November 2006, the basalt section in the Anderson 11-5 was completed and DHS Rig 7 was in place, to drill to about 14,000 ft. The Lang rig was disassembled (Fig. 3), ready for transport to the third and northernmost wellsite, Brown 7-24.

In its first-quarter operating results, announced May 7, Delta Petroleum said the Brown 7-24 well was “drilling and should reach total depth in early summer.”

EnCana spokesman Alan Boras confirmed drilling status to OGJ and said, “Generally, the Lang rig has worked very well, with no real trouble time, such as getting stuck in the hole. Overall, the drilling pace has been slower than expected due to the challenging nature of the geology. We are happy with the performance of the technology for drilling through the basalt.”

Additional drilling

Delta Petroleum holds about 468,000 net acres in the Columbia River basin and is permitting three wells of its own, south of the Encana wells and near the Oregon border. Delta will spud its first operated well, “Alpha,” in third-quarter 2007 with drilling contractor DHS Drilling.

Delta expects to drill the Alpha well to 14,000 ft, including 8,000 ft of basalt. Delta said that DHS Drilling believes it can drill 200 ft/day in basalt and 400 ft/day in sedimentary sections. Additional wells planed by Delta include “Beta,” McBride 28-13, and Gray 31-23.

ConocoPhillips is the third-largest acreage holder, with about 400,000 net acres, but has not yet announced plans to drill.

Denver’s Exxel Energy Corp. holds about 340,000 net acres in the basin (98% working interest). In an April 25 presentation at the OGIS conference in New York, Exxel described it as an “emerging basin-centered gas accumulation,” with “world-class” untested anticlines and an existing pipeline infrastructure. The company has identified several prospects and will continue to evaluate its acreage.

RC drilling elsewhere

Calgary’s K2 Energy Corp. used reverse-circulation techniques to drill four wells in the Cretaceous Bow Island formation in northwestern Montana (OGJ, Mar. 11, 2002, p. 42). K2 had a hard rock mining rig from Midnight Sun Drilling, Whitehorse, Yukon, for the shallow, low-pressure gas drilling. Midnight Sun used air hammers and dual-wall drill pipe with a 2 7/8-in. inner string inside a 4½-in. outer string. K2 said using the reverse-circulation technique nearly eliminated formation damage and yielded commercial gas flows exceeding the results from rotary-drilled wells.

RC pipe

Calgary’s Foremost Industries LP manufactures four types of dual-tube, RC pipe, and accessories (www.foremost.ca).

A 10-ft length of 6 5/8-in. OD pipe typically weighs 480 lb (218 kg). A triple stand of dual-tube, RC pipe weighs about 4,800 lb.

References

- “Extraordinary Depths Require New Technology-In Boart Longyear’s Lang Exploratory Division,” Drill Bits magazine, Spring 2006, www.nda4u.com

- Roche, P., “Battling the basalt,” Nickle’s New Technology magazine, January-February 2006.