Model studies thermal effects of liquid pipeline colocation

Changes in the vertical relative position of two liquids pipelines laid in the same trench (one crude, one products) produce only small changes in the temperature of the crude oil, allowing this approach to be used as a viable alternative to dual trenching. Small buried delocalization is acceptable and the relative position of the two pipelines can be determined by the small thermal change which occurs.

This article uses a numeric model based on China’s West Pipeline to demonstrate the viability of pipeline colocation.

West Pipeline

China saved money and minimized environmental damage during the 2005 construction of the West Pipeline by laying several hundred kilometers of crude and products pipelines in the same ditch. This technique required a specific thermal analysis of the interaction between the two pipelines.

Most crudes China produces are either waxy with high pour points or viscous and heavy. Poor flow properties call for heating the crude oil, and temperature along the pipeline is a key variable.1-2 The products pipeline may absorb heat from the crude pipeline, thereby lowering the crude’s temperature. Avoiding crude oil gel required study of this problem.

The interval between the two pipelines affects the heat transfer between them. Detailed thermal analyses studied the effect of the interval on temperature of the crude oil, finding that when the pipeline interval is larger than 1.2 m, the temperature decrease of the crude oil is acceptable.

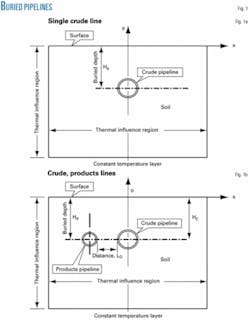

The calculations, however, assumed that the axes of the double pipelines were on the same horizontal plane (Fig. 1). Though this is an ideal condition, construction cannot guarantee it. Changes in the heat transfer with variation of the relative vertical position of the two pipelines stand as another important issue in the thermal analysis.

This article uses a numerical method to study this issue.

The numerical calculation used the same pipe used for the West Pipeline-813 mm OD, 11-mm WT crude oil line, 559 mm OD, 7-mm WT products line-and set the distance between them at 1.2 m. The study also used the physical properties of North Xinjiang crude oil and 90-octane gasoline.

Researchers set the buried depth of the crude oil pipeline at a constant of Hc = 1.6 m and used Equation 1 (see accompanying box) to set the buried depth of the products pipeline and determine relative vertical position, thereby determining the effect of the vertical relative position of the two pipelines (Fig. 1).

Dc and Dp represent the ODs of the crude oil pipeline and the products pipeline, respectively. The last two buried depths of the products pipeline are not be realistic and were included so that the actual pipeline depth could be intervenient.

Table 1 shows other parameters of the study.

Calculations of a single crude oil pipeline and single products pipeline under the same conditions as the dual line provide a point of comparison (Fig. 1).

Mathematical model

Assumptions made in the mathematical model include:3

- Uniformity of temperature of crude oil and products on the same pipeline cross-section; i.e., the temperatures of the crude and the products lines are a function of time and axial location of the pipeline.

- Simplification of the soil anisotropy outside the pipelines as isotropy.

- Simplification of three-dimensional unsteady heat conduction outside the pipes as two-dimensional unsteady heat conduction; neglecting the axial heat conduction.

- Selection of the thermal influence region of the crude oil pipeline as the computational domain, the ranges of which are -10 m ≤ x ≤ 10 m and -10 m ≤ y ≤ 10 m (Fig. 1). The temperature of the soil 10 m down from the ground surface is constant; 10 m away from the crude oil pipeline is the heat-insulating boundary.

The hydraulic gradient and oil heat transfer in steady operation using these assumptions yield Equations 2 and 3.

Equations 4 and 5 show the heat conductive equation of wax deposition, pipe wall, and corrosion protective covering under a polar coordinate system, and the heat conductive equation of the soil under a Cartesian coordinate system.

Results, analysis

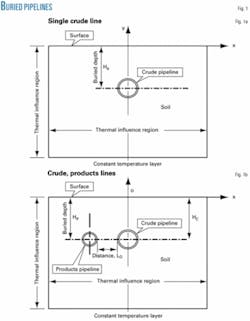

The left column of Fig. 2 shows the grid generation of the soil’s computational domain when the axes of the pipelines are not on the same horizontal plane, while the right column shows the soil temperature field at the pumping station’s outlet.

The soil temperature fields on the right side of the crude oil pipeline are basically the same, meaning the effect of the products pipeline on the soil temperature field is minor. Similar conclusions emerge at different pipeline distances.

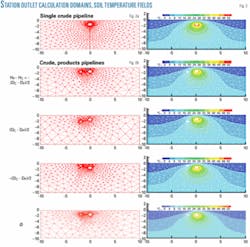

The isothermals on the left side of the crude oil pipeline changed greatly with variation of the vertical relative position of the two pipelines. The heat loss of the hot crude oil pipeline at the pumping station outlet increased due to the heat absorption of the products pipeline. Moreover, as the products pipeline’s buried depth increased, the heat loss of the crude oil also experienced a small increase. The vertical relative position of the two pipelines did not significantly affect heat loss on the crude oil.

Analysis showed that when there are two pipelines in one ditch, the heat loss of the crude oil pipeline is greater than that of the crude oil pipeline laid in a ditch on its own at distances less than 80-100 km and is smaller than that of the single crude oil pipeline at distances greater than 80-100 km. Across the first 80-100 km, the significant temperature difference between the hot crude oil and the cold products increases the products temperature and decreases the crude oil temperature. After 80-100 km have been traveled, the heat absorption of the products pipeline diminishes and the products even release heat due to the minor temperature difference between the two pipelines.

Fig. 3c shows that the temperature of the products first increases then decreases. Fig. 3b and Fig. 3c show the temperatures of the crude and products separately. Table 2 details the underlying data.

A new parameter, Tdiff, describes the thermal effect on the crude oil pipeline clearly. The parameter consists of the temperature difference at the same location of a pipeline coexisting with another and one laid on its own. Fig. 3b, in which the curves have good superposition with each other, shows that Tdiff of the crude oil is minor when the vertical relative positions of the two pipelines change.

The maximum Tdiff of the crude oil and products lines both decrease gradually with the shallower buried depth of the products pipeline (Table 2). Table 2 also shows the maximum Tdiff and its location.

Changing the physical properties of the soil, the outlet temperature, and the throughput rates of crude oil and the products had little effect on the results. The comparison described here varied the depth of the products pipeline while keeping the crude oil pipeline fixed. Reversing these conditions would produce similar results.

Acknowledgment

The authors acknowledge the support of the National Research Foundation for the Doctoral Program of Higher Education of the Peoples Republic of China, the Scientific Innovation Project of PetroChina Co. Ltd., the National Natural Science Foundation of China, and the Chinese Ministry of Education in completing this article.

References

- Zhang Jinjun, “Technologies for pipelining high-pour-point and viscous crudes and their development,” Engineering Science, Vol. 4 (2002), No. 6, pp. 71-76.

- Luo Tanghu, “Rheology and transportation process of crude oil,” First Edition, pp. 36-52, Beijing, 1995.

- Cui Xiuguo and Zhang Jinjun, “Determination of the thermal influence zone of buried hot oil pipeline on steady operation,” Journal of the University of Petroleum, China, Vol. 28 (2004), No. 2, pp. 75-78.