SPECIAL REPORT: Wellheads provide means for abandoning hurricane-damaged wells

Diver-installed wellheads facilitate plugging and abandoning wells damaged in recent storms in the Gulf of Mexico.

Storms and hurricanes in 2004 and again in 2005 extensively damaged many platforms in the gulf. The US Minerals Management Service estimates that in 2005 Hurricane Katrina destroyed 46 platforms and extensively damaged 20, while Rita destroyed 69 platforms and extensively damaged 32. Accurate numbers of damaged wells are unavailable, but one estimate is that the industry will have to plug and abandon more than 1,000 wells because of these storms.

Most of these damaged and destroyed platforms and wells were in water depth less than 400 ft and installed in the late 1960s and 1970s.

Wellhead design

One approach to abandoning these wells is for divers to install a new wellhead such as that designed and development by Superior Wellhead Inc., Houston.

In June 2005, Wild Well Control Inc., Houston, approached Superior Wellhead (SWI) about developing the wellheads for abandoning wells damaged by Hurricane Ivan in 2004. SWI said that it developed the diver and remotely operated vehicle (ROV) friendly system in less than 3 months, with the first one installed in August 2005.

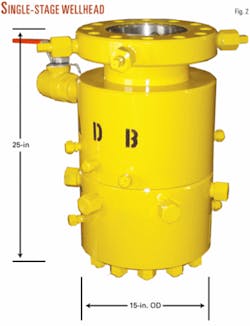

SWI designed the system to work with existing hand tools in the diver’s current standard kit. The system can accommodate multiple strings and multiple casing and tubing sizes and has all the external functional parts such as tie-down screws and slip-activating pins with an oversized design for easy handling, requiring only diving gloves.

The system also includes a sealing assembly that employs a noninterference packoff type seal, in lieu of the standard interference-type seal.

SWI says companies may leave the wellheads on the wells in areas that allow the structures to be reefed in placed.

In other areas, MMS requires the conductor and casing to be cut below the mud line. In these cases, the wellheads are used during the plugging work, such as wireline and cementing, and removed later on.

Well abandonment

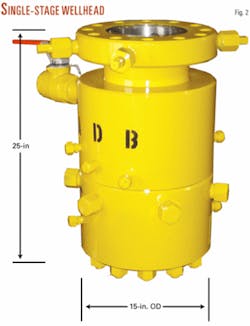

In abandonment of damaged wells, the first step is to remove platform debris. After this, divers aided by surface cranes on work vessels can cut the casings in a “wedding cake” fashion and install the wellheads (Fig. 1). Because well conductors are often close together, work with an ROV is not possible. In most cases the wellhead installation requires saturation divers for work in water depths in excess of 100 ft.

With the casing strings prepped, divers can then test the annulus string with a strip-over or wrap-around tester. The wellhead is then installed to isolate the production or surface strings. The wrap-around annulus isolation tool also has been used to meet additional MMS test requirements without the removal of the wellhead.

Time is a critical element because work vessels can cost more than $250,000/day. SWI says that with its Express Connect system divers have completed a typical installation in less than 1 hr.

The Express Connect wellhead (Fig. 2) has a full bore access and is for casing ranging from 7 to 13 3/8-in. in size, with pressure ratings of 3,000, 5,000, and 10,000 psi. The wellhead has a standard bowl profile for the tubing hanger and recessed seals.

The tubing hanger can accommodate single, dual, or triple strings and has a control-line option.

SWI says that to date operators have installed more than 120 of its wellheads.