Great Wall drilling swiftly in Thailand

Chinese crews in Thailand drilled about 375,500 ft with an individual land rig in 2006. This performance was achieved during a continuous contract with a single operator, PTT Exploration and Production Co. Ltd., in two areas, 400 km apart.

Great Wall Drilling Co., a subsidiary of China National Petroleum Corp. (CNPC) Services & Engineering Ltd., was set up in 1993. The company currently provides drilling services and operates rigs in Thailand, Indonesia, Canada, US, Mexico, Cuba, Venezuela, Chad, Algeria, Tunisia, Libya, Egypt, Sudan, Oman, Syria, Iran, Pakistan, Kazakhstan, Uzbekistan, and Azerbaijan.

Last month, GWDC (Thailand) Ltd. told OGJ that there were 180 GWDC rigs operating outside China.

As of July 2005, the total CNPC rig fleet numbered at least 618 rigs, predominantly 1,000-1,500-hp rigs (OGJ, July 18, 2005, p. 37).

In June 2005, Dan Pickering characterized CNPC and subsidiary Great Wall Drilling as the “global land drilling X-factor,” based on its potential to affect the balance of land rig supply and demand worldwide.1

Unfortunately, company web sites are infrequently updated and provide little information about the rig fleets, projects, or technical capabilities of the equipment.2 Last month, GWDC told OGJ that it is redesigning the company web site and that additional information would be available soon.

Thai drilling record?

Great Wall Drilling Co. (Thailand) Ltd., a drilling service provider in Thailand, has a drilling rig and a workover rig in country. GWDC Thailand’s Rig GW-80 has been working for state-owned PTT Exploration and Production PCL in the PTTEP S1 area, in Pitsanuloke, and Kampangpetch, and Supanburi provinces, for several years (Fig. 1).

Rig GW-80 was built in China by Honghua Machinery Manufacture, Sichuan. Model ZJ 50DBS uses variable frequency drive and is rated to 5,000m (16, 400 ft). All rig components were manufactured in China, except for the Caterpillar generators and the Varco TDS-11SA top drive.

The 1,500-hp rig features a driller’s cabin and console with joystick controls, and can handle triple stands of pipe (Fig. 2). Triple stands of pipe are handled manually; there is no automated pipe handling equipment (Fig. 3).

Over a 26-month period (August 2004-October 2006), this land rig drilled 78 wells, completed 3 workovers, was skidded 27 times over a total skidding distance of 3,150 m, and moved 55 times over 380,000 km.

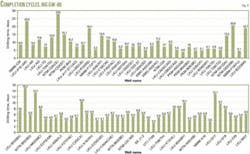

The drilling completion cycle ranged 3.6-27.6 days/well for 60 wells drilled in 2005-06, with an average around 7 days (Fig. 4). Rig move cycle time ranged 1.5-5.1 days/move.

During the first 10 months of 2006, Rig GW-80 drilled 40 wells, 1 workover, 1 sidetrack, and 100,500 m (about 330,000 ft). Crews skidded the rig 18 times over a total of 1,612 m and moved the rig 26 times.

During the entire year, 2006, GW-80 drilled 114,482 m (375,500 ft). It may be a land rig footage record for the country and the company, but OGJ cannot confirm record status. There is no central database for land rig performance outside the US.

The Land Rig Newsletter ranks the top 75 “most active” land rigs each year, based on footage drilled in the US. Publisher Richard Mason told OGJ that the GW-80’s performance in Thailand in 2006 would rank 17th in the US. The top two US rigs finally broke the 500,000 ft. barrier in 2006.

Procedure

GWDC (Thailand) detailed the operations procedure for a typical well drilled in the PTTEP S1 area. The well program was designed by PTTEP’s drilling department.

The first section is drilled from 850-1,250 m in about 12 hr, using a 12¼-in. PDC bit with a 9 5/8-in. motor and MWD and fresh water. The inclination is increased from 15-60º. The choke manifold, pipe ram, and SCR are tested. After reaching TD, the driller backreams with the bottomhole assembly (BHA). The crew sets 9 5/8-in. casing and cement in 7-8 hr. The well is then pressure tested for 3-4 hr.

The driller reenters the hole with an 8¾-in. BHA and drills with overbalanced mud weight, drilling 2,500-3,500 m in about 40 hr. Pulling out of hole requires about 12 hr. Two wireline logging runs take about 10 hr. The crew sets and cements 7-in. casing in about 15 hr. Completing the well (without perforating) requires about 10 hr. Another half hour is required to nipple-down the BOP.

GWDC, North America

According to RigData, Great Wall Drilling Co. of America placed 88th in a list of the top 100 drillers ranked by footage drilled in the US in January 2007 (www.rigdata.com). Company rigs drilled 33,750 ft, started 3 wells, and drilled 1 directional well in January.

Houston-based Andrews Technologies Inc. (ATI) facilitated a “3+2” contract (3-year initial term, 2-year renewable), $165 million contract with GWDC America LLC, a subsidiary of GWDC China, for 10 land rigs in the US. The Chinese-owned, fabricated, and operated rigs range 750 hp to 1,500 hp and began operating in Texas and Louisiana in late 2005.

The first two rigs, GW85 and GW86, left Tianjin port on Oct. 5, 2005, according to China National Petroleum Corp. (www.cnpc.com.cn/english) and GWDC. The two drilling crews are from Daqing No. 1 and No. 2 Well Drilling Cos.

According to ATI, the rigs arrived in the Port of Houston on Dec. 14, 2005. Both rigs were transported to drillsites in Louisiana and completed spud-in in late December 2005 for Aspect Energy LLC, a privately held, Denver-based, independent oil and gas exploration and investment company. On Jan. 17, 2006, GWDC completed the first well successfully.

The fourth GWDC America rig, 1,500-hp, spudded its first well in Sulphur, La., on Aug. 16, 2006. The fifth and sixth rigs, 750-hp and 1,000-hp, cleared the Port of Houston in September 2006 and went to work for Aspect Energy.

By January 2007, GWDC had nine Chinese-built rigs operating in the US, according to The Land Rig Newsletter (Jan. 31, 2007).

Andrews Technologies de Mexico SA de CV and Beijing’s Great Wall Drilling Co. have an exclusive partnership agreement for Mexican. Four drilling rigs were operating in PEMEX’s Southern Region 2002-05.

In April 2006, ATI Mexico secured two contracts, worth $43 million, for GWDC America to provide two 750-hp land rigs to Pemex Exploration and Production for drilling near Villahermosa, Tabasco state.

Since it is the nature of records to be broken, we will see what other rigs will approach or exceed the accomplishment of GW-80 in 2006.

References

- Oil Service Topical Report, Pickering Energy Partnership Inc., June 7, 2005.

- www.gwdc.china.com; www.cnpcse.com.