New program enhances API cement monogram

Recently, an industry task force studied the value of the API monogram for oil well cements and developed a program to enhance the value of the monogram for manufacturers and end users.

Want API cement for your next well? The question is not as simple as it appears. Do you mean cement that conforms to the API specification for well cement or cement produced by a company that holds the API monogram? These are not necessarily the same thing.

Products such as pipe, valves, motor oil, and cement can carry an API monogram. Many products can be sold as meeting API specifications, but do not carry the monogram.

The API monogram is not a requirement of the API specification. API standards are voluntary and may be used by anyone desiring to do so. However, only those manufacturers that are licensed by API are allowed to mark their products with the API monogram. To be licensed, the company must pass strict requirements for the development and use of quality programs, and participate in annual audits of the facilities.

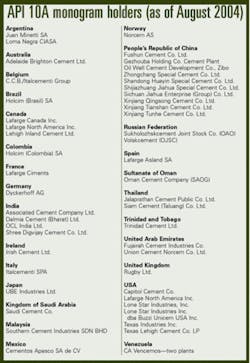

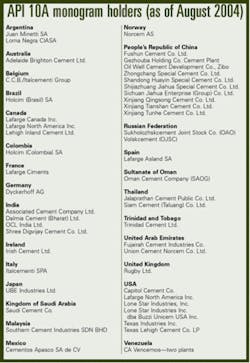

Correction The following companies were inadvertently omitted from the article by Benge, Carruthers, and Gardner on API oil well cements (OGJ, Sept. 13, 2004, p. 69). Argentina: Petroquimica Comoforo Rivadiva SA Indonesia: P.T. Indocement Tunggal Prakarsa Tbk. P. T. Semen Cibinong P. T. Semen Padang Russian Federation: Open Joint-Stock Co. "Spasskcement" Thailand: Raysut Cement Co. (SAOG) If you want a product monogrammed, you need to order it that way. Insisting on the monogram means the purchaser values this warranty of compliance from a manufacturer that participates in the API quality program. There is no recourse through the API for pursuing product noncompliance if the manufacturer is not licensed.Throughout the 1990s, manufacturer participation in the monogram dwindled to only 43 in 1999, from 51 licensed manufacturers in 1991. API-monogrammed cement is widely available in some areas but surprisingly absent in others. For example, there are no licensed manufacturers of API Class G cement in the US. The Class G cement currently manufactured in the US may be manufactured to the API standard but cannot be monogrammed as API Class G cement.

Manufacturers choose not to participate in the monogram program for varied and complex reasons. One of these is a lack of operator insistence on monogrammed materials.

Another, related reason is the general perception that the monogram adds little to the intrinsic value of well cement, and certification is merely a "paper chase" in search of the proper initials on the correct form. Some manufacturers have complained that some auditors had little knowledge of well-cement production and led audits that failed to focus on the requirements of Specification 10, Specification for Materials for Well Cementing.

API Subcommittee 10 on Well Cements formed a manufacturer's advisory group in 1998, to investigate the reasons for declining participation in the monogram program. Working with the API quality committee, the advisory group explored options and developed an improved audit process. The new process focused on selecting and developing a pool of auditors who specialize in the particular requirements in Specification 10.

The program began by emphasizing auditor training. A group of industry experts was retained to develop training manuals and materials explaining the requirements of Specification 10. These individuals worked with members of the user and manufacturer communities to ensure that the training materials were accurate and comprehensive.

With the training materials in hand, the next step was selecting a pool of auditors to participate in the program. API employs 59 auditors in its worldwide monogram program. Of these, 11 were selected for specialized training in the particular specifications related to well cement.

Training manuals were supplemented with 1.5 days of hands-on instruction in well-cement manufacture at a cement plant in Pryor, Okla., run by Buzzi Unicem USA Inc., a subsidiary of Italy's Buzzi Unicem SPA.

This was followed by 1.5 days at Tulsa-based Chandler Engineering Co. LLC, a wholly owned business unit of Ametek Inc., for in depth training on laboratory testing equipment and procedures. All of the formal training and hands-on experience was capped with a written examination.

The responsibilities of this select auditor pool are divided geographically. Four auditors cover cement plants in North America, one auditor works in South America, three auditors are assigned to Asia and Australia, two auditors cover Europe, and one auditor handles the Middle East.

The first audits under the new program were performed in early 2003. The feedback has been positive. Auditors were pleased with the training and licensees find the auditors more knowledgeable in the specifics of well-cement manufacture. Even those licensees whose audits uncovered areas for improvement reported the overall experience to be positive and worthwhile. The API quality group reports an increase in the number of audit items related to particulars of the specification (as opposed to general quality system issues).

The number of licensed manufacturers of well cement has grown since 1999, reaching a total of 52 in early 2004 (see box). The advisory group, now with task group status, continues to pursue ways to strengthen and enhance the monogram.

The authors

Glen Benge (glen.benge@ exxonmobil.com) is an engineering associate with ExxonMobil Development Co., Houston. He holds a BS in chemistry from Southwestern Oklahoma State University and attended graduate school at Oklahoma State University. Benge is a member of SPE, API, and ISO and is the chairman of the API subcommittee on well cements.

William R. Carruthers ([email protected]) is technical manager, oil well products at Lafarge North America in Metropolis, Ill. He holds a BA in chemistry from Baylor University (1968). Carruthers is a member of API, SPE, ASTM, and ICMA, and serves as chairman of the cooperative testing and monogram committee at API, and as general chairman of ICMA.

Craig Gardner (craig.gardner @chevrontexaco.com) is a senior advisor (cementing) and team leader for the cement and fluids team at ChevronTexaco Energy Technology Co., Houston. He holds a BS in chemistry from the University of Houston. Gardner is a member of SPE, API, and ISO and a past chairman of the API subcommittee on well cements.