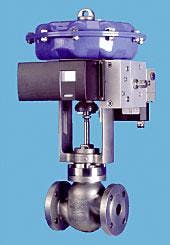

New offshore valve positioner

The intelligent valve positioner ARCAPRO Typ 827A can now also be mounted to stroke positioners in accordance with VDI/VDE 3847. It's suited for offshore applications.

The standardized mechanic and pneumatic interface between positioner and actuator allows a pipeless mounting that is interchangeable among different manufacturers.

The newly designed mounting has a compact construction of high mechanical strength. Because the mounting is accomplished by only by two bolts, the changing of the positioner is easily done with short notice, the company points out.

A new version of the ARCAPRO with communication via Foundation Fieldbus has now completed the row of different bus technologies (besides HART and Profibus).

The operation, configuration, and enhanced diagnosis are easy to handle via pushbuttons and display and independent from the communication on site. Positioners are approved by ATEX, FM, and CSA as explosionproof and intrinsically safe.

One of the main tasks of the 827A is to verify whether preadjusted set points have been exceeded. Deviations are shown in the display by corresponding error codes. For remote monitoring, an alarm programming via the failure outlet is available. The listing of all wear related information allows the procurement of replacement parts in time as well as the planning of necessary service intervals. The supervision system in total is designed to help reduce maintenance costs as much as 70%, the firm says.

Source: ARCA Regler GMBH, Kempener Str. 18, D-47918 Tönisvorst, Germany.

New version of dynamic process simulator

A new version of Dynsim dynamic simulator features increased performance, enhanced usability, and interoperability.

Dynsim can be used in refining, petrochemical, chemical, and engineering and construction operations.

Dynsim version 3.2 has been upgraded to allow seamless integration with Pro/II enhanced steady-state flowsheeting and optimization simulator solution. Pro/II is a process simulation program that performs mass and energy balances for a range of plant processes. The solution opens and automatically translates steady-state Pro/II simulations into Dynsim dynamic simulations.

Dynsim 3.2 provides for increased reaction capabilities to model kinetic reactions expressed in a form consistent with Pro/II. Reactions can be added to standard Dynsim equipment models. The pipe model can simulate a plug flow reactor while the drum model can simulate a continuously stirred tank reactor.

The upgraded Dynsim solution also has other improvements for increased simulation speed such as local thermodynamic property calculations. There also are new equipment models to simulate more types of plant equipment and additional enhanced capabilities in the area of custom equation handling.

In addition, an OLGA interface has been added to the Dynsim upgrade for simulation scenarios operating in multiphase transport environments. OLGA is a simulation solution for transient multiphase flow of oil, water, and gas in wells and pipelines with process equipment. OLGA capability requires a separate third-party license.

Dynsim enables users to leverage dynamic simulation model equity. The firm says Dynsim excels in plant simulation operations by allowing users to use the same model in multiple applications, such as process design studies, control evaluations and checkouts, operator training, and operational analysis.

Source: SimSci-Esscor, Invensys PLC, Carlisle Place, London SW1P 1BX, UK.

New unit verifies that drill collars are nonmagnetic

The Magnetoscop 1.069 is a lightweight, portable instrument that measures low-level magnetic fields (up to 180 hz), magnetic interference fields, and the magnetic permeability of nonferromagnetic materials.

One of its uses is confirming that nonmagnetic drill collars used in drilling equipment are indeed nonmagnetic.

When used with a field-gradient sensor, the instrument measures disturbances in the local magnetic field caused by the presence of magnetic inclusions in the drill collar. The sensor is inserted into the center of the inner bore of the drill collar and either pulled through the bore while the drill collar is held stationary or the drill collar is transported relative to the stationary sensor. Each installation must be considered separately because local magnetic masses such as building supports, cranes, auxiliary machinery, and even the material handling equipment used to support the drill collar during inspection can negatively influence the measurement.

When used with a permeability sensor, the instrument measures absolute magnetic permeability in a range of 1.00001-2.000. The hand-held permeability sensor is positioned on the surface of the material at the location where the measurement is to be taken. The measured permeability value can be read directly from the instrument's LCD display. Traceable magnetic permeability standards are available for calibration.

Source: Foerster Instruments Inc., 140 Industry Drive, RIDC Park West, Pittsburgh, PA 15275.