Enhanced NGL recovery process selected for Neptune gas plant expansion

Enterprise Products Operating LP and partner Marathon Oil Co. conducted a study for the design and construction of a second 300 MMcfd NGL-recovery train at the Neptune plant in St. Mary Parish, La. The companies selected IPSI LLC's Enhanced NGL-Recovery Process after comparing available NGL recovery technologies for the new train.

IPSI's technology replaces conventional propane refrigeration with a self-refrigeration and stripping gas package that allows up to 20% more processing capacity with the same residue-gas compression horsepower as in the existing train. A novel demethanizer reflux design was also incorporated into the unit.

The two enhancements should allow ethane recoveries of 90+% and maintain the flexibility to maximize propane recovery during ethane-rejection mode. The new train is scheduled to start up by the end of 2003.

Neptune gas plant

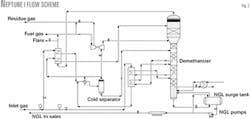

Enterprise and Marathon started up a cryogenic NGL recovery plant at St. Mary Parish in February 2000 (Fig. 1). This plant, Neptune I, processes Gulf of Mexico natural gas produced by Shell Oil Co., Marathon, and others.

null

Neptune I uses a standard gas subcooled process (GSP) to treat 300 MMcfd of 2.8-GPM (gal/Mcf) gas. A Solar Turbines Inc. C-406 centrifugal compressor, driven by a Mars 100 gas turbine, recompresses the residue gas.

When the plant started up in February 2000, the inlet gas was significantly richer than the design anticipated (4+ GPM vs. 2.8 GPM). To improve ethane and propane recoveries, mechanical refrigeration was later added to make Neptune I a refrigerated GSP plant.

At times, the plant has processed inlet gas volumes of up to 330 MMcfd with an ethane recovery of 70-80%.

To process newer discoveries from the Southern Canyon of the Gulf of Mexico, another nominal 300 MMcfd train, Neptune II, is currently under construction (Fig. 2). Technip-Coflexip, which also built the first unit, is the contractor for Neptune II.

Design requirements

Inlet gas to the Neptune plants is projected to average more than 4 GPM for many years after start-up. To select the optimum process for Neptune II, we evaluated refrigerated GSP, which Neptune I uses, and other proprietary NGL recovery processes.

Technology suppliers were asked to provide information on component recoveries, any refrigeration or other compression requirements, and an estimated incremental cost of the process compared to a base GSP plant.

For each technology provider, we set the same common design parameters:

- For ease of maintenance and savings on common spare parts, use the same recompressor and gas turbine as used in Neptune I.

- Ethane recoveries of 90+%, and an indication of the additional refrigeration and compression horsepower required.

- Ability to reject ethane with approximately 90% C3 recovery.

Process options

Since the early 1980s, Ortloff Engineers' GSP (OGJ, May 3, 1982, pp. 281-90) was the preferred process for high ethane-recovery NGL plants.1

The main feature of this process is that some of the feed gas is condensed, subcooled, and flashed to the demethanizer as a top feed. This top feed acts as a reflux, which helps the GSP tolerate more feed CO2 and provides greater ethane and propane recoveries for the same horsepower as the older designs.

Another advantage of the GSP design is that the plant can also operate in ethane-rejection mode while still maintaining significant propane recovery. All of the current "state-of-the-art" NGL recovery technologies are basically enhancements of the GSP concept.

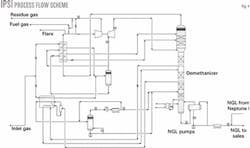

Fig. 3 is a schematic diagram of Neptune I, which uses a refrigerated GSP design.

We also evaluated one other well-known and efficient process from a leading technology supplier for Neptune II. The process requires a propane refrigeration system and can provide greater than 95% ethane and almost 100% propane recoveries.

In addition, during the ethane-rejection mode, propane recoveries are significantly higher than what can be achieved with other processes.

null

The IPSI stripping-gas process generates internal refrigeration by expanding a liquid stream from the demethanizer. Flashed vapor is compressed and returns to the demethanizer as stripping-enriching gas while the flashed liquid combines with the demethanizer product.

This design's advantage vs. conventional propane refrigeration is that no separate propane chiller, surge tank, or economizers are required. This makes the capital investment for the IPSI refrigeration system lower than a propane refrigeration system.

A second subcooled reflux stream to the demethanizer further enhances the IPSI process. This second reflux stream uses the liquid from the cold separator that is subcooled by heat exchange with the demethanizer overhead stream. This second reflux forms the second feed to the column's top.

Process selection

Duplicating the Neptune I plant was the cheapest capital investment option. By copying an existing plant, we would have saved at least half of the detailed engineering man-hours required for the Neptune II design.

Another advantage was that the plant operators were already fully familiar with the process and would have required minimum training to become familiar with Neptune II's start-up and operation. The disadvantage was the relatively higher compression costs for the same or lower recoveries.

The other competing processes can attain high ethane and propane recoveries that are not possible with a refrigerated GSP design; however, these processes require more recompression horsepower, which results in higher capital cost and plant fuel consumption.

We could not economically justify the incremental installation and operating costs for the additional horsepower due to our projected ethane and propane margins. For the Neptune II design, the enhanced IPSI process provided the optimum solution. The advantages of this process design are that it:

- Uses the least total horsepower to achieve the same recoveries as competing processes and, therefore, has the lowest compression costs.

- Has the lowest up-front capital cost.

- Produces the highest net present value to plant owners and gas producers.

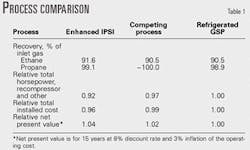

Table 1 summarizes the process comparisons.

In the IPSI process (Fig. 4), compressed stripping gas vapor provides all the demethanizer bottom reboiler duty for controlling C1:C2 or CO2:C2 ratios in the recovered NGLs.

We decided to install an electric cogeneration plant at Neptune. The power generator uses waste heat from the two gas turbines' exhausts to generate most of the power required by the processing trains.

Because the IPSI process does not require an external heat source for the demethanizer reboiler, the turbine waste heat is used to generate an additional 15% power vs. the other process designs. Because the decision for cogeneration was not made at the time of process selection, this incremental power benefit was not included in the comparison. Only the IPSI process, however, could maximize power recovery.

IPSI Enhanced Process

IPSI developed the enhanced process2 to achieve high recovery levels of ethane and heavier hydrocarbons, reduce residue gas horsepower, and avoid the need for an external refrigeration system.

The process uses a slipstream from the demethanizer's bottom as a mixed refrigerant. The mixed refrigerant is totally or partially vaporized, providing refrigeration for inlet-gas cooling. Other processes accomplish this using a more costly external refrigeration system that includes compressors, condensers, refrigerant accumulators, economizers, and refrigerant storage.

Vapor generated from the self-refrigeration cycle is recompressed and recycled back to the tower's bottom, where it serves as stripping gas. This eliminates the need for inlet-gas cooling via external refrigeration and also helps demethanizer operations by

- Lowering the temperature profile, which permits better energy integration for inlet-gas cooling via side reboilers, resulting in reduced heating and refrigeration requirements.

- Reducing or eliminating the need for external reboiler heat, which saves fuel.

- Enhancing the relative volatility of key components at typical pressures, which improves separation efficiency and NGL recovery. It alternatively allows increased tower pressure for typical recoveries, reducing residue gas compression requirements.

The self-refrigeration design can augment to almost any leading NGL-recovery technology. It enhances the operational efficiency and reduces capital and operating costs of those processes.

In the Neptune II plant, IPSI's stripping-gas refrigeration combines with the standard GSP design. The process is further improved via a second reflux stream to the demethanizer. This second reflux stream is generated by subcooling and flashing the cold separator liquids above a second packed section in the demethanizer.

The advantages of the second reflux are:

- Increased ethane recoveries with no additional horsepower.

- More total reflux to the top section of the demethanizer. For a fixed amount of total reflux, the process can reduce the GSP split and send more flow to the expander to generate more horsepower. This allows a lower demethanizer pressure, which further improves recoveries.

null

Gas chilling, turboexpander

Dry feed gas from the dehydration unit splits into two streams. Exchange with the cold residue gas (overhead product from the demethanizer) chills one of the streams in the warm gas-gas exchanger. The gas-liquid exchangers chill the other inlet-gas stream.

The chilled inlet-gas streams from the two exchangers combine and flow to the warm separator. Liquid from the separator subcools in the cold gas-gas exchanger and flashes above the demethanizer's second packed section.

Vapor from the separator splits into two streams. Most of the vapor goes to the turboexpander. Expansion of this vapor stream produces refrigeration and cools the gas and also generates mechanical work to drive a booster compressor on the same shaft.

The expanded stream feeds to a packed section in the demethanizer for further fractionation. Remaining vapor condenses in the cold gas-gas exchanger using refrigeration from the cold residue gas. The condensed stream feeds to the demethanizer's top packed section as the top reflux.

Stripping gas refrigeration

Stripping gas is the main feature of the IPSI design. A side liquid draw from the bottom section of the demethanizer expands (decreasing its temperature) to provide refrigeration for the inlet gas. The partially vaporized stream from the lower-side reboiler then feeds the stripping-gas separator.

The stripping-gas compressor boosts the pressure of the vapor from the stripping-gas separator. This hot compressed stream provides the bottom reboiler duty for the demethanizer.

The stripping gas cooler ensures that the demethanizer receives adequate heat input for meeting the C1:C2 or CO2:C2 ratio in the bottom NGL stream. Liquid from the stripping gas separator, which also meets the NGL product specifications, pumps back to the demethanizer's bottom.

Demethanizer, residue-gas compression

The demethanizer strips methane out of the ethane and heavier hydrocarbons recovered as NGL. Residue gas from the demethanizer's top flows through the cold gas-gas exchanger and the warm gas-gas exchanger.

Warm residue gas from the warm gas-gas exchanger feeds the compressor side of the expander-compressor (booster compressor).

Compressed residue gas from the booster compressor discharge further compresses to final delivery pressure via the residue gas compressor. A small portion of the residue gas is withdrawn from the outlet of the booster compressor for use as plant fuel gas.

Process performance, comparison

When we compared the three processes, we found that the IPSI stripping gas refrigeration design offers these advantages:

- Greater than 90% ethane recovery with lower total compression horsepower and capital cost. The typical GSP design with no refrigeration would achieve about 64% ethane recovery with the Neptune II design composition. External propane refrigeration provides a higher ethane recovery with the GSP design. Propane refrigeration horsepower required for a 90+% ethane recovery is 40% higher than that for stripping gas refrigeration.

- Fully integrated process refrigeration with improved reliability and separation efficiency. We compared the IPSI stripping gas design and conventional propane refrigeration design based on the feed gas composition and conditions in the Neptune II design. For both designs, ethane recovery level and, therefore, demethanizer pressure were the same.

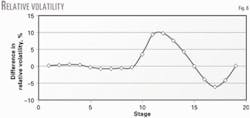

A tray-to-tray differential temperature profile (Fig. 5) shows that the IPSI design has a lower temperature in the column's middle (Trays 11-15) than external propane refrigeration.

This is usually where the side reboiler is located.

A lower column temperature means better heat integration. Because the ethane recoveries are the same, the top and bottom temperatures are also almost identical in both designs. Fig. 6 compares the relative volatility of methane-ethane for both designs.

The IPSI design shows better relative volatility for trays with lower temperatures in Fig. 5. Better relative volatility means an easier methane-ethane separation.

- Although the plant design is based on a 300 MMcfd feed-gas rate at design composition, it can operate at 350 MMcfd at a lower recovery level while producing gas and liquid products within specification.

- The stripping-gas system can also work in the ethane-rejection mode. The temperature profile in the column's bottom section is normally too high for integration with feed-gas cooling. The stripping-gas design, however, can still provide refrigeration and achieve a high propane recovery even when in ethane-rejection mode.

- The stripping gas self-refrigeration system provides overall energy integration and completely replaces the propane refrigeration system. Refrigerant supply and makeup is no longer a concern.

- The stripping-gas refrigeration system can handle variations in feed-gas composition. Simulations with fixed design equipment sizes show that the variation of ethane recovery is within 2% for feed-gas compositions of 3.1-4.5 GPM.

- The system does not require an external heat source for the demethanizer reboiler.

The stripping gas package can be used to revamp most existing plants to provide additional refrigeration and higher recoveries or additional capacity.

References

1. Elliot, D. G., Chen, R.J.J., Brown, T.S., Sloan, E.D., and Kidnay, A.J., "The Economic Impact of Fluid Properties on Expander Plants," Proceedings of the 70th Annual GPA Convention, Gas Processors Association, Tulsa, 1991; pp. 59-64.

2. Yao, J., Chen, J.J., and Elliot, D.G., "Enhanced NGL Recovery Processes," US Patent No. 5992175, Nov. 30, 1999.

The authors

Pervaiz Nasir is director, technology, at Enterprise Products Operating LP. He previously worked as a consulting engineer at Coral Energy, a subsidiary of Shell Oil Co. Pervaiz holds a PhD in chemical engineering from Rice University, Houston.

Welby C. Sweet is an advanced senior process engineer for Marathon Oil Co.'s technology organization. His primary focus is process modeling of oil and gas production, processing, and pipeline systems. Welby holds a BS (1976) in chemical engineering from the University of Toledo.

Doug Elliot is president, chief operating officer, and cofounder of IPSI LLC, an affiliate of Bechtel Corp., Houston. He has helped develop much of the technology currently used in the gas processing industry. Elliot holds a BS from Oregon State University and an MS and PhD from the University of Houston, all in chemical engineering. He has been a member of GPA's research steering committee since 1972. He is a fellow of AIChE and a Bechtel Fellow.

Roger Chen is senior vice president of IPSI LLC. He has more than 28 years' experience in research, process design, and development in gas processing, and oil and gas production. Chen holds a BS from National Taiwan University and an MS and PhD from Rice University, all in chemical engineering. He is a member of AIChE, ACS, and GPA's research steering committee.

R.J. Lee is manager of intellectual property for IPSI LLC. His areas of expertise include oil and gas processing, cryogenic industrial gas separation, and LNG and enhanced NGL recovery technologies. Lee holds a BS (1981) from National Taiwan University and an MS and PhD from Purdue University, West Lafayette, Ind., all in chemical engineering.