Crude-by-rail safety standards call for better tank cars, reduced speeds

Rachael Seeley, Editor

The US Department of Transportation has proposed new rules for transporting crude by rail that are designed to lessen the frequency and consequences of train accidents by reducing the speed of trains, improving tank car standards, and setting more-robust testing and classification guidelines for crude cargoes.

The DOT proposal, drafted by the Pipeline and Hazardous Materials Safety Administration (PHMSA), would require tank cars constructed after Oct. 1, 2015, to conform to new design requirements-known as DOT Specification 117-for enhanced thermal, top-fitting, and bottom-outlet protection systems as well as improved tank head and shell-puncture resistance.

"Today's proposal represents our most significant progress yet in developing and enforcing new rules to ensure that all flammable liquids, including Bakken crude and ethanol, are transported safely," said Transportation Sec. Anthony Foxx.

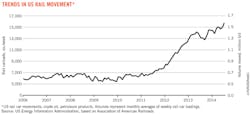

The number of trains transporting crude oil across the US has increased sharply in recent years-rising from 9,500 rail carloads in 2008 to 415,000 rail carloads in 2013.

According to the US Energy Information Administration, the amount of crude and refined petroleum products moved by US railroads increased 9% during the first 7 months of 2014, compared with the same period in 2013. The American Association of Railroads (AAR), one of the rail industry's largest trade organizations, estimates that monthly car loadings of oil and petroleum products were near 16,000 carloads/week in July (see figure).

Production growth in the Bakken shale is a driving force behind the increase. North Dakota this year surpassed California to become the second largest oil-producing state in the US. Production topped 1 million b/d in April, compared to 790,000 b/d a year earlier, and the state now supplies nearly one out of every eight bbl of oil produced in the US.

Bakken producers are using rail to circumvent pipeline bottlenecks and capitalize on arbitrage opportunities in coastal markets.

The North Dakota Pipeline Authority reported that 59% of oil produced in May left the state in rail cars. The average shipment of Bakken crude travels more than 1,000 miles from its point of origin to coastal refineries.

Rail car standards

Three tank car design options are proposed for the new DOT-117 rail car standards.

Analysis by the law firm Sidley Austin LLP said the options contain several common factors, namely the use of "a 286,000-lb car constructed with normalized steel and equipped with full height, 1⁄2 in.-thick head shields; reclosing pressure relief devices; minimum 11-gauge, weather-tight jackets; bottom-outlet handles that can be removed or are designed to prevent unintended actuation during a train accident; thermal protection capable of withstanding a 100-min pool fire; top-fitting protection; and enhanced breaking."

The three options are distinguished by their shell thickness and enhanced breaking-system requirements. Two options call for tank car shells with a thickness of 9⁄16 in., while the third calls for a thickness of 7⁄16 in. Each option also contains a unique braking standard; one calls for the use of a two-way end-of-train device, the other for distributed power braking, while the third requires electronically controlled pneumatic brakes.

Within 4 years, PHMSA intends to phase out the use of DOT-111 tank cars for the shipment of Bakken crude unless the cars are retrofitted to meet new standards. Until the phase-out date, trains carrying older tank cars will be permitted to continue transporting crude, but their speed will be limited to 40 mph. High-hazard flammable trains (HHFTs) that do not meet enhanced breaking requirements may be limited to 30 mph.

PHMSA expects the majority of DOT-111 tank cars, or about 66,000, will be retrofitted and about 23,000 will be transferred to Alberta for use in transporting less volatile bitumen.

Depending on the final rail car standard selected, PHMSA said the cost of retrofitting older cars could range from $26,230 to $33,400 per car, not including the cost of out-of-service time and additional fuel and maintenance costs.

Estimates compiled by Bloomberg indicate the cost of modifying older cars could rise as high as $60,000/car. The majority of tank cars in the US are owned by shippers and leasing car companies.

Operational requirements

PHMSA considers any train carrying 20 or more carloads of Bakken crude, or other Class 3 flammable liquid such as ethanol, an HHFT.

The agency's proposal contains operational rules that would subject HHFT routes to risk assessments and limit those with tank cars that meet the new DOT-117 standards to speeds of 50 mph, falling to 40 mph in areas with more than 100,000 people. It would also codify into law an emergency order that requires carriers to notify state emergency-response commissions before any train carrying more than 1 million gal of crude (31,700 bbl) passes through.

Additional testing requirements are also proposed to ensure crude is classified and characterized properly.

In August 2013, PHMSA initiated a series of unannounced inspections in North Dakota to ensure that shippers were properly classifying crude for transportation and to better understand the unique characteristics of Bakken oil.

Operation Classification determined that Bakken crude is classified properly but, the final report found, "the crude has a higher gas content, higher vapor pressure, lower flash point and boiling point and thus a higher degree of volatility than most other crudes in the US, which correlates to increased ignitability and flammability."

PHMSA went on to conclude that the current tank car most frequently used to transport crude, the DOT-111, "is not an adequate container for flammable crude involved in an incident or derailment."

High-profile accidents

As the amount of crude being shipped by rail in North America has increased, so too has the number of mainline train accidents involving crude. According to PHMSA, the number of these accidents in the US increased from zero in 2010, to five in 2013, and five in the first 7 months of 2014.

Several high-profile accidents have placed the industry under increased scrutiny (See table). The most deadly was a July 2013 incident in the Canadian resort town of Lac-Megantic, Que. A derailed train caught fire-leading to 47 deaths and the destruction of part of the town. The incident involved a train with 72 tank cars, each filled with 30,000 gal of Bakken crude.

The Canadian government responded by implementing a plan to replace or retrofit older, DOT-111 tank cars within 2 years.

Voluntary improvements

AAR supports efforts to improve the safety of crude-by-rail transportation.

Edward Hamberger, president and chief executive officer of AAR, said: "We believe that federal tank car standards should be raised to ensure crude oil is moving in the safest car possible based on the composition of the product being moved. The rail industry also wants the existing tank car fleet upgraded with retrofits or phased out of service as soon as possible."

Major freight railroads in the US have already begun taking steps to improve the safety of crude shipments. A voluntary safety initiative announced in February included several operational aspects of the DOT plan.

According to AAR, the initiative includes a pledge to reduce to 40 mph the speed of HHFTs traveling through densely populated areas, a 27-point routine risk assessment to determine the safest route for HHFTs, and a $5 million donation toward a safety training program for local first responders. The initiative also called for increased safety inspections of mainline routes and equipping HHFTs with faster emergency breaking systems.

"We share the administration's vision for making a safe rail network even safer and have worked together to swiftly pinpoint new operating practices that enhance the safety of moving crude oil by rail," Hamberger said.

AAR reports the overall safety record of railroads has been improving for decades, and recent years have been the safest in rail history. Data compiled by the Federal Railroad Administration show the train accident rate in 2013 was down 42% compared to 2000, the employee injury rate was down 47%, and the grade-crossing collision rate was down 42%.

Vital transportation link

Rail transportation has become a vital link in the transportation network that moves crude oil from unconventional plays to market-particularly in the Bakken shale. Lynn Helms, director of the Oil and Gas Division of the North Dakota Department of Mineral Resources, said he expects the shipment of crude by rail will remain an important part of the state's oil transportation system.

Regarding PHMSA's proposed rules, Helms said, "It's too early at this point to determine what impacts this could have on North Dakota oil production; however, we will review the 200-page document and work with the North Dakota Pipeline Authority on how to best advise the Industrial Commission moving forward."

Also planning to review the proposal was the American Petroleum Institute. API Pres. Jack Gerard said the trade group plans to submit detailed comments during the 60-day public comment period, which commences when the proposed rules are published in the Federal Register.

"The government can and should take steps to ensure greater safety without stalling the energy renaissance that is creating good jobs, growing our economy, and improving America's energy security," Gerard said.

Finalized rules are expected to take effect early next year.