SCHLUMBERGER PIONEERS RECORD DEEPWATER OPEN-HOLE GRAVEL PACK COMPLETIONS

Two extremes define Perdido’s early development wells: The water is very deep, and the reservoirs are very shallow below the mudline. The difficulty for drillers is the small difference between the amount of pressure required to control the wellbore and the amount of pressure required to fracture the rock around it.

In the Silvertip field, where Schlumberger completed Perdido’s first two development wells, the narrow pressure window is so low that conventional open-hole gravel pack treatments would be at risk.

“The challenge is to pump the gravel slurry at a low enough pressure to keep it from fracturing and entering the formation, without reducing the effectiveness of the gravel placement,” says Salah Al-Harthy, Schlumberger well completion engineer. “The efficiency of the gravel pack directly affects the productive life of an open hole well. Any voids will expose the screens to erosion and possible well failure.”

Perdido’s first two development wells were drilled from a floating rig in the Silvertip field, in 9,400 feet of water. The targeted zone was the Oligocene-Frio sands, a portion of the Lower Tertiary that consists of as many as six separate reservoirs from 1,500 to 2,500 feet below the mudline.

The wells reached a maximum total depth of 16,513 feet, with horizontal open-hole length of 2,300 feet. Since the Oligocene-Frio sands may compact as they are produced, well planners decided to complete these sands with a horizontal open-hole gravel pack to enhance the longevity of these completions in a highly compressive reservoir.

“There were two primary challenges in completing these sands with horizontal open-hole gravel packs,” Al-Harthy says. “The first challenge was the narrow pressure window and the second challenge was the selection of carrier fluid.”

Designing the completions

The fracture gradient of the targeted Oligocene-Frio sands was about 7,100 psi. With reservoir pressures of 6,700 psi, that meant the pressure window for placing the gravel pack was only 400 psi. The risk of such a narrow operating window is that the reservoir rock can fracture during treatment, causing premature screen-out and insufficient packing around the screens.

The requirement for the gravel packing carrier fluid needed to have enough carrying capacity to suspend the gravel and remove the filter cake after the gravel was placed. It also needed to have a low corrosion rate around the sand control screens, since the wells were being completed more than a year before first oil.

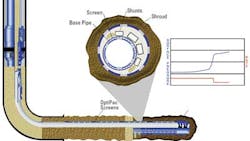

To overcome these challenges, Schlumberger used two of its flagship technologies, the OptiPac* Alternate Path† systems, and its ClearPAC* MS gravel packing fluid system, to ensure a complete pack around the sand control screens.

OptiPac Alternate Path systems use shunt-tube technology to fill the voids that can form during gravel packing even under fracturing conditions. The shunts are installed along the screens, each with a series of evenly placed nozzles.

“When a bridge forms, the slurry naturally diverts into the shunts,” Al-Harthy says. “When slurry encounters a nozzle facing a void in the open hole, it flows out to fill the unpacked annulus, and the process continues until the interval is fully packed.”

OptiPac systems are part of an integrated approach that ensures that screens are fully protected in high flow-rate wells, and is utilized in-conjunction with SandCADE*, gravel-pack design and evaluation software to help engineers design, execute and evaluate the entire job.

ClearPAC MS, which is an advanced viscoelastic surfactant, was selected as the carrier fluid on the first two Silvertip wells because of its excellent sand suspension capabilities, even at very low shear rates. The sand suspension and low friction pressure characteristics allow it to perform exceptionally well in the long intervals of both open hole and cased hole completions. The ClearPAC MS fluid also incorporates a breaker system (based on MudSOLV technology) to help dissolve filter cake that remains in the wellbore after the gravel pack is completed. By combining the breaker system with the carrier fluid this allowed Shell to eliminate the need to reenter the well, saving valuable rig time.

“To compensate for the narrow operating pressure, we also modified the mixing equipment on our stimulation vessel,” Al-Harthy says.

This equipment, called the POD* programmable optimum density blender, mixes the fluid and the gravel before it enters the pump. The POD normally operates at rates of above six barrels a minute, but for the Perdido wells the equipment was modified to accept half the rate of fluid and proppant, to maintain pumping pressures within the narrow margins.

“We conducted a number of trials and extensive modeling beforehand to make sure that the equipment, fluid and overall design would perform as planned,” says Al-Harthy.

Monitoring in real time

Throughout the process, Shell and Schlumberger engineers in distant locations were able to collaborate efficiently in real time using the InterACT* connectivity, collaboration, and information system. InterACT’s robust design allows it to continue working, even in areas with marginal communication links.

MudSOLV: Filter Cake Breaker

Part A shows nonaggressive, slow-acting, MudSOLV solutions remove the filtercake more uniformly, resulting in higher retained permeability across the entire interval.

Part B shows aggressive treatments like acid create localized open areas (wormholes or pinholes) in the filtercake, leaving large areas of filtercake unremoved, generally over areas having lower permeability.

Working the plan

“We really did our homework,” Al-Harthy adds. “Using powerful models and simulations, we worked together in a highly collaborative environment with Shell, to evaluate all the risks and to ensure successful execution. Perdido is a frontier development, so there were many uncertainties, but at the end of the day the modeling was correct and these jobs were performed as designed. The work we did on those first two wells will guide many of Perdido’s future well completions.”

*Mark of Schlumberger

†Mark of ExxonMobil Corp.; technology licensed exclusively to Schlumberger

Schlumberger

1325 S. Dairy Ashford

Houston, TX 77077

U.S.A.

Tel: +1 281 285 1300

Website: www.slb.com/sandcontrol