Ukraine gas transit system expanding, modernizing to meet demand

The Ukrainian natural gas system that moves most of the supplies between Russia and eastern and western Europe is in the process of expanding and upgrading equipment and facilities to meet expected surges in demand.

Evaluation and modernizing of the system's compressor stations along with expansion of the pipeline and underground storage facilities will boost system capacity for east-to-west transit by 160 billion cu m/year (bcmy; 5.6 tcf/year).

Location

The distinctive characteristic of gas industry development in Europe is the location of the main sources of gas production in remote Western Siberia, the deserts of Central Asia and Northern Africa, and the shelves of the Barents and Caspian seas.

The largest exporter of natural gas to the European market is Russia whose gas supplies to the western European countries comprise 17% of consumption and 55% of central European consumption.

By 2010, Russian gas' share in European energy supply will have increased. Gas production in Russia comes mostly from the gas fields of Western Siberia, some 4,000-4,500 km from the borders of Central European countries.

Increasing distance between the main sources of gas production and the main consumption regions creates extremely high demands on the reliabilities of gas transmission systems that for the most part transit other countries.

Transmission system

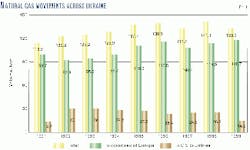

Its historical background and beneficial geographical position made Ukraine the world's largest junction of Russian gas in transit to eastern and western Europe. Since 1991, transit-gas deliveries to central and western Europe as well as to Turkey increased by 19%, reaching 118.7 bcm in 1999 (Fig. 1).

Despite development of such alternative routes for Russian gas supply as the Yamal-Europe and "Blue Stream" gas pipelines, Ukraine will continue to be the main transit route in the near term.

At the same time, consuming 75 bcm/year of gas, Ukraine is one of the world's largest gas consumers. That is why the Ukraine gas transmission grid can provide transmission solutions for Russian gas transit as well as supply natural gas to its own industrial and residential consumers.

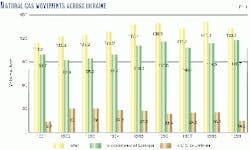

As of the beginning of 2000, the gas transmission system in Ukraine consisted of 36,000 km of gas pipelines including 22,800 km of gas mainline and 13,200 km of laterals, 112 compressor stations, and 13 underground gas-storage facilities.

System inlet capacity on the northern and eastern borders is 290 bcmy (10.2 tcf/year) and delivery capacity on the western, southwestern, and southern border is about 170 bcmy (Fig. 2).

The major transit gas pipelines are the following:

- Urengoy-Uzhgorod, "Progress," "Soyuz," Ivatsevitchi-Dolyna-Uzhgorod, and Torzhok-Dolyna, all of which transport gas to Slovakia and Hungary and to other European countries.

- The Yelets-Kremenchuk and Kremenchuk-Ananiiv-Tiraspol-Izmail gas pipelines, which provide gas to Moldova, Romania, Bulgaria, and other Balkan countries.

Today, Russian gas is exported through Ukrainian main gas pipelines to 18 European countries and Turkey.

There are interconnection pipelines between transit-gas pipelines that are able to move sufficient volumes of gas among individual gas pipelines, providing high reliability and mobility in operation with gas flows especially in combination with a large complex of underground gas-storage facilities.

The system consists mainly of large-diameter pipeliners:

- Pipelines of 1,420 mm (56 in.) OD comprise 16.4% of the system.

- Those of 1,020-1,220 mm (40-48 in.) OD comprise 24.6%.

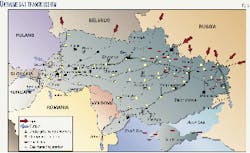

In service age, gas pipelines cover the following range (Fig. 3):

- Less than 15 years - 41%.

- 15 to 24 years - 28%.

- 25 to 34 years -15%.

- More than 35 years -16%.

- About 0.1% has been in service for more than 50 years.

It must be noted, however, that long-term use is usual for gas pipelines 820 mm (32 in.) or smaller. At the same time, the lines of 1,020 -1,420 mm OD, which form the transit system, are relatively new: 90% of them has been in service for fewer than 24 years, and about a half of them have been used fewer than 14 years.

Compression

The situation with compressor stations is more complicated.

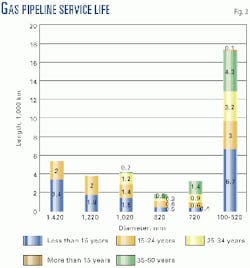

They consist of 714 gas compressor units of 20 types of domestic and foreign production with total power of 5.5 million Mw. Most of the stations, about 80%, consist of gas turbine compressors with unit power of 6.3, 10, 16, and 25 Mw.

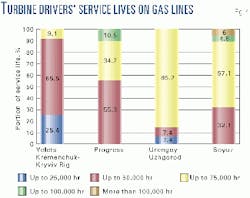

About 20% of gas compressor unit fleet is nearing or has already passed its design service life and needs to be replaced. Fig. 4 shows the service life of compressors on the main system.

Obviously, proper maintenance of gas transmission system requires the necessary service and sufficient repair, reconstruction, and modernization of equipment, beginning with the compressor stations with depreciated and low-efficiency units.

Inspection, repair

One of the keys for ensuring the reliability of the gas pipelines is regular in-line inspection by intelligent pigs. An inspection program began in 1996 on transit-gas pipelines 1,220 and 1,420 mm OD, using equipment and technology of H. Rosen Engineering GmbH, Lingen, Germany.

Such inspections make detecting and locating pipe defects more efficient and allow more confident decisions on further use or repair of the pipeline.

During 1996-1998, inspections were carried out on 1,170 km of large-diameter gas pipelines, resulting in a defects-removal program carried out during 1999. In 2000, about 885 km of gas pipeline were inspected.

An in-line inspection of about 10,000 km of the pipeline, including almost all transit lines, is to be completed by 2005. A large portion of this inspection will be done with an ultrasonic pig developed by Ukrainian company Slavutych.

This pig has its own by-pass that permits up to 50% of flow during operations. It is equipped with its own driver and braking system that allows the pig to be stopped when a more detailed inspection of the defect area is necessary or when the pig must move against the gas flow.

Because in-line inspection is expensive, there are other methods available. For example, complex analysis of corrosion condition can be made by on-surface equipment with computerized C-SCAN 2000 from Dynalog Inc., Bloomfield Hills, Mich. Intensive measuring of the cathodic-protection potentials complements the inspection program that uses intelligent pigging.

To provide high reliability and long life for the gas lines during their construction and repair, only the pipe with factory-applied coating has been used since 1990. They are produced at the Khartsyzk pipe mill in Ukraine.

During the last few years, two-component polyurethane coating Protegol UR-32-55 has been used for coating repair and replacement on gas pipelines.

Ukraine gas transmission lines also use both an epoxy-sleeve technology for repair marketed by British Gas and T.D. Willamson Inc.`s technology of hot tapping without discharging gas into the atmosphere.

For in-service gas pipelines working at 7.5 Mpa (1,100 psi), manual electric welding developed by the E.O. Paton Electric Welding Institute, Kiev, has been used. Also developed by the same institute, a mobile laboratory for gas pipeline inspection has shown good results, especially on road and rail crossings, by using acoustic emission.

Ukrainian Gas Research Institute has almost finished developing a remote inspection system of gas mainlines that uses heat vision and other equipment mounted on airplanes and helicopters.

Testing and implementation of the new methods and technical devices for inspecting, repairing, and increasing the reliability of gas pipelines are concentrated in the inspection center within the gas transmission company Ukrtransgas.

The professionals of the center are also at work on vibro-inspection of gas compressor units developed by the Ukrainian Gas Research Institute, also a unit of Ukrtansgas. The stationary system of vibro-control and inspection enables evaluation of a compressor unit without breaking its junctions.

Reconstructing stations

An important role in increasing the economy and reliability of gas transit supply is played by the program of reconstructing compressor stations without interruptions in gas movements. The program replaces overworked as well as obsolete gas compressor sets, turbines, and control systems with new ones made in Ukraine and which comply with the modern industry standards.

Ukrainian design organizations and such factories as Zorya (Mykolayiv), Motor Sich (Zaporizhzha), and Frunze (Sumy) created and started to produce modern gas turbines of marine and aircraft type and gas compressor units based on centrifugal compressors with 6.3, 10.0, 16.0, and 25.0 Mw of power for the mainlines as well as for underground gas-storage facilities' compressor stations with 6.3 and 16.0 Mw of power.

The distinctive characteristics of the new gas-turbine drivers are high efficiency (31.0-31.5% for 6.3-6.7 Mw drivers and 35.0-36.0% for 10.0-25.0 Mw engines) and lower air pollution.

The reconstruction program for compressor stations developed through 2004 calls for upgrading 50 stations by replacing 221 gas-turbine engines.

Plans call for new marine-type gas turbines at compressor stations along the Urengoy-Uzhgorod, Progress, Soyuz, Yelets-Kremenchuk-Kryvyi Rig, Dolyna-Uzhgorod, and Ananiiv-Tyraspol-Izmail transit-gas pipelines instead of Frame-3 and Frame-5 turbines and turbines produced in Russia, and also stations at some underground gas-storage facilities.

Gas-turbine engines of aircraft type were scheduled for reconstruction as part of the stations of Soyuz and Yelets-Kremenchuk-Kryvyi Rig transit-gas pipelines and five underground gas-storage facilities, which are connected to the transit-gas pipeline system.

For the last 5 years, 31 new Ukrainian turbines of 25 Mw, 16 Mw, 10 Mw, and 6.3-6.7 Mw were installed on compressor stations of the Urengoy-Uzhgorod and Progress transit-gas pipelines, the Shebelynka-Dykanka-Kyiv pipeline, and on compressor stations of the Dashava underground gas-storage facility and gas pipeline by which the transit transfer of gas is provided to the southern region of Russia.

Particular attention was paid to gas-turbine driver with 16 Mw capacity and efficiency of 45% designed by Mashproject (Mykolayiv) and with water regeneration and vapor injection into the gas turbine burning chamber.

The engine will be installed on Stavysche compressor station of the Progress gas pipeline.

The new type of gas compressor set provides:

- Up to 15 million cu m/year in fuel-gas savings.

- Receipt of high-quality technical water at an average of 1.2 tonnes/hr.

- High ecological characteristics with the exhaust gas temperature of 40-50 degrees C.

After the program is complete, the share of Ukrainian-made gas turbines will grow to 70% of the total, and average efficiency of the entire fleet will rise to 32.7%. This will save about 1 bcmy of fuel gas, about 20% of total gas-transmission system needs.

Metering; storage

Upgrading gas metering stations along the transmission system and residential users' equipment saves gas and lowers capital waste. For the last few years, half of the metering stations equipped with old-fashioned self-writing mechanical devices were retrofitted with modern microprocessor-based automatic calculators, "Super-flow" and "Flowtech" types through which 80% of the gas now flows.

The gas-metering stations are reconstructed or newly built on Ukrainian borders with Russia, Poland, Slovakia, Romania, and Hungary, which guarantees the reliable account of transit gas.

Based on a system from Serc Controls, the control system for Soyuz, Urengoy-Uzhgorod, and Progress transit-gas pipelines is being built.

Step-by-step automation of dispatcher control will spread over other such pipelines as Yelets-Kremenchuk-Kryvyi Rig gas pipeline along the transit route to Romania.

An integral part of Ukrainian gas transmission system, the nation's underground gas-storage facilities provide reliability of transit-gas supply as well as supply to the domestic consumers.

The network of underground gas-storage in Ukraine is one of the largest in Europe, with capacity of more than 30 bcm working gas.

The main underground gas-storage facilities are in western Ukraine. Their capacity is 2.5 times more than the needs of this region. Being connected to the major transit-gas pipelines, for many years they were used to regulate seasonal and peak fluctuations in gas deliveries to the central and western European countries, and also seasoning and long-term storage of gas for foreign clients' demand.

Because of the possible increase in moving Russian gas through Ukraine in 2005 to 125-130 bcm and in 2010 to 145-155 bcm, more underground storage is planned. The construction of Torzhok-Dolyna pipeline with 1,420 mm diameter will be completed after the setting of four compressor stations.

It will be possible to transfer up to 29 bcmy of gas from Russia to the Ukrainian borders with Slovakia and Hungary. The Khust-Satu Mare gas pipeline of 700-mm diameter is built by which Russian gas will be transported to the northern east of Romania.

The Tarutino and Ananiiv compressor stations and the second line of Ananiiv-Izmail gas pipeline and Talne-Ananiiv gas pipeline of 1,420 mm diameter are being built that will increase gas supply to the Balkan countries and Turkey by 15 bcmy.

The realization of above mentioned projects will give the possibility to increase the capacity of Ukrainian transit-gas pipeline system to Europe up to 160 bcmy.

A high reliability and maneuverability of Ukrainian transit-gas pipelines will let them play an important role in an integrated European gas supply system.

The authors

Vasyl Rozgonyuk is deputy chairman of the board of Naftogaz. Previously, he was a deputy chairman of the board of Ukrgazprom. Rozgonyuk graduated from Ivano-Frankivsk Oil & Gas University with a doctorate in petroleum and gas engineering.

Zynoviy Osinchuk is deputy head of research and development for Naftogaz, a national joint-stock company, Kiev. Previously, he worked for Ukrgazprom joint-stock company, also as head of its research and development. Osinchuk graduated from Lviv Politechnika University with a doctorate in petroleum and gas engineering.