Equipment/Software/Literature

New ball valve fitting for transmitter changeout

A new ball valve fitting on the market permits changeout of a process pressure transmitter mounted on a vessel without having to empty the vessel.

The fitting is provided with a mounting flange on one side, which is screwed to the vessel, and with a socket on the other side for holding a process pressure transmitter type D84 with process connection FG4.

If the ball valve fitting is closed, the transmitter can be safely and easily installed or removed, the company points out. The pressure acting on the ball valve can be up to 2 bar.

The fitting is available with flange sizes DN 50, 80, and 100, and ANSI 2, 3, and 4 in.

Source: Vega Grieshaber KG, Am Hohenstein 113, D-77761 Schiltach, Germany.

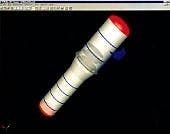

Pressure vessel software updated

PVElite Version 4.10 is an enhanced edition of this firm's integrated vessel design and stress analysis software. Updates include the ASME 2000 addenda and ASCE 98 wind code as well as provisions to use the 1999 material data base. Other enhancements include user bolt loads in the tube sheet programs, simultaneous calculations for corroded and non-corroded thick expansion joints, separate entry of m and y factors for partition gaskets, the addition of graphical results processing in rigging analysis, a transparency option in the 3D viewer, and ladder specifications. Also, the TEMA and ASME tube sheet programs now perform multiple load cases.

In addition to these new features, PVElite incorporates current pressure vessel codes and standards such as ASME BPV, British Standard 5500, ASCE #7, Uniform Building Code, National Building Code. ANSI B16.5, TEMA, and WRC Bulletin 107 and 297. PVElite provides engineers, designers, estimators, fabricators, and inspectors with complete design of tall towers, horizontal vessels, and individual vessel components. The software is designed for quick start-up, and its graphical modeling capabilities are easy to use and allow for quick data assembly and vessel analysis, the company points out.

The company also has released CodeCalc Version 6.30, an updated edition of its software for design and analysis of pressure vessel and heat exchanger components. This version incorporates updated standards including ASME Section VIII, Division 1, 2000 addenda, and British Standard 5500 Annex G. Other enhancements include a link to FEA nozzle analysis. Also, ASME and TEMA tube sheet modules now support multiple load cases.

Source: Coade Inc., 12777 Jones Rd., Suite 480, Houston, TX 77070.

New derrick screen vibrator

The Martin screen vibrator, an 1,800-rpm explosionproof vibratory drive, promises to upgrade existing derrick equipment.

It provides up to 7,000 lb of centrifugal force to size, sort, or separate material. It features low maintenance requirements; the only specified service is bearing lubrication every 2,000 operating hr, the company says. No automatic oiling system is required. The vibrator uses heavy-duty cylindrical roller bearings that are quiet in operation.

It holds UL, CSA, and EEx certificates as suitable for hazardous-duty locations. It features a dusttight, watertight, cast aluminum case sealed to IP66-7 standards.

The vibrator is a direct fit bolt-in replacement to upgrade the original equipment vibratory drive on Models E, K, L, and M vibrating screens manufactured by Derrick Corp., Buffalo, NY.

Source: Martin Engineering, One Martin Pl., Neponset, IL 61345.

Thermal dispersion flow sensors

The new TD3800 Series thermal dispersion flow sensors are adjustable to a range of flow rates, have no moving parts in the flow stream, and operate largely independent of pipe diameter.

The series includes single-point and dual-point flow monitors. They feature LED status indication, fast response time, and a minimum/maximum monitoring function. They are suited for water, oil, air and media with similar thermal conductivity, with nonlinear trend outputs (4-8 v dc) for medium temperature and flow.

Sensors are available with either no delay, a 60-sec switch on delay, or 10-sec changeover delay. Explosionproof and weatherproof options are available.

Source: Scientific Technologies Inc., Automation Sensors Div., 429 S. Main St., Logan, UT 84321