Equipment/Software/Literature

New line of valve actuators

WellGuard, a new line of valve actuators for wellheads and production flow lines, is used in conjunction with Bettis-designed valve bonnets to provide open and close control for major brands of API 6A through-conduit reverse-acting gate valves. These fluid powered diaphragm actuators can also be used with API 6D and ANSI B16.34 valves with Bettis-designed bonnets.

Units are suited for onshore and offshore installations and in H2S and C02 applications. Actuators can be used with valve sizes 1 13/16 through 4 1/16 in. API.

Source: Emerson Valve Automation, Box 508, Waller, TX 77484.

Unit analyzes refinery gas streams quickly

A new high-speed system characterizes the composition of petroleum gases rapidly. The AC Hi-Speed refinery gas analyzer determines and reports the composition of most refinery gas streams in 5 min.

The system characterizes:

- C1-nC6 hydrocarbons.

- Inert gases including nitrogen, hydrogen, helium, oxygen, carbon monoxide, and carbon dioxide.

- Hydrogen sulfide, which requires an additional analysis time of 2 min.

It also characterizes the composition of LPG and butane streams in 3 min.

The new analyzer uses an Agilent Technologies 6890 Series gas chromatograph with electronic pneumatics control. This firm configures the gas chromatograph with application specific valves and columns, a thermal conductivity detector, and a flame ionization detector.

Source: AC Analytical Controls Inc., 3494 Progress Drive, Bensalem, PA 19020.

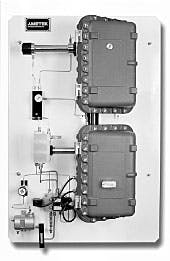

New hydrogen sulfide analyzer

The new Western Research Model 933 H2S analyzer uses a proprietary frontal elution chromatography technique combined with a 900 Series high-resolution, multiwavelength UV optical bench. The result is a process analyzer capable of detecting low levels of H2S while operating unattended for 6 months or more, the company says.

The unit is intended for use in gas sweetening processes, pipeline quality and custody transfer, gas blending stations, and synthetic gas production.

Other features include self-recovery following high H2S concentration events and fast response to increasing and decreasing H2S concentrations.

The analyzer's frontal elution chromatography sampling system eliminates interfering compounds (carbonyl sulfide and methyl mercaptan) to help ensure an accurate analysis of the H2S content via direct UV-absorption spectroscopy. It incorporates dual chromatography columns; while one column is conditioning the sample gas, the other is automatically regenerating.

Source: Ametek Process Instruments, 455 Corporate Blvd., Newark, DE 19702.

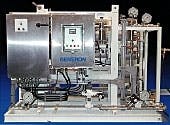

On-site nitrogen generation for offshore operations

This new compact and lightweight HPMB 6500 Series unit provides on-site nitrogen generation for offshore drilling operations. The unit's small footprint

and ultralightweight aluminum casing help suit it for the limited space requirements offshore.

Units are skid-mounted, stand-alone systems that use this company's membrane technology to provide an uninterrupted supply of gaseous nitrogen to purities of 95-99.5%.

This system can produce high purity gaseous nitrogen in flows from a few standard cubic feet or meters to over 520 scfh from a source of compressed air. This membrane technology works by filtering oxygen from a stream of compressed, dry air via millions of individual fibers, each about the diameter of a human hair, to yield gaseous nitrogen at any purity up to 99.9% or greater.

Source: Generon, Box 3043, Malvern, PA 19355.