Full-scale test of deepwater hot-tap system set for early 2002

Williams Cos. Inc., Tulsa, and three other companies have spent 4 years and about $5 million to conceive and design a diverless, deepwater hot-tapping system that will undergo full-scale testing this spring on a Williams pipeline in the US Gulf of Mexico. For this test of commercial viability, Williams will spend another $5 million.

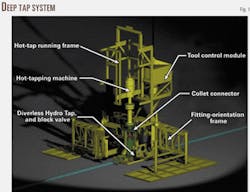

The system, call Deep Tap, has already been patented in the US, and international patents are pending (Fig. 1).

The other companies that have been involved in the project are Oil States HydroTech Systems Inc., Houston; Oceaneering International, Houston; and T.D. Williamson Inc., Tulsa.

The hot-tap machine developed by these four companies has been tested in a hyperbaric chamber at a US Navy's test facility to confirm its operability at extreme water depths. A systems integration test was also administered in Houston during December 2000 and January 2001 at Oceaneering.

All the parts, pieces, and procedures came together as designed. Throughout the test, some modifications to improve visibility and redundancy were identified and implemented.

With the prototype engineered, fabricated, and tested, Williams and Oceaneering originally scheduled the first test installation for fall 2001, but several large-scale construction projects have delayed that installation to 2002.

After that, Williams plans to perform other deepwater taps on its infrastructure along the coasts of Texas, Louisiana, Mississippi, and Alabama. The development consortium also plans to market the service commercially.

The need

As oil and gas developments in the Gulf of Mexico and around the world continue into deeper waters, the need for infrastructure to support that growth is increasing. More than half of all new pipelines scheduled for installation in the Gulf of Mexico over the next 3 years are in waters deeper than 1,500 ft. Tying into closer existing pipelines could reduce the cost of developing this infrastructure.

In some locations, provisions have been made to allow for a tie-in by means of a lateral tie-in sled or pipeline-end manifold. But in many locations, equipment is not available, and the only options are to complete a hot tap tie-in or build a pipeline back to existing pipelines in shallow water.

In depths from 1,500 ft to 10,000 ft, diver intervention is infeasible, leaving producers no solutions.

The goal of Williams' Deep Tap consortium is to provide the shortest, most direct way to tie new production into existing infrastructure without spending millions of dollars on additional pipeline and riser costs to make connections at platforms.

The plan is to use remotely operated vehicles (ROVs) dispatched from a single vessel to apply hot taps on pipelines up to 20 in. OD that are operating at pressures up to 2,000 psi with ANSI pressure ratings up to 1,500 psi.

The primary benefits of Deep Tap are that it allows for a deepwater tie in where no tie-in hub exists and that it can be completed without interrupting normal pipeline operations.

The process is similar to current hot-tapping technology except that the work is performed completely by a ROV using a newly developed diverless hot-tap clamp, hot-tapping machine, and ocean-floor support equipment.

Deepwater producers stand to gain the most from this technology. Marginal discoveries can be aggregated into existing pipelines with excess capacity and eliminate the need to build transmission lines back into shallower water. This could bring small-to-moderately sized reserves on stream that could not independently support platforms and export pipelines.

Technical challenges

In 1997, Williams' field services business contracted three companies specializing in subsea hot tapping and deepwater marine construction to determine if diverless hot tapping was possible with current technology.

Oil States HydroTech Systems Inc. designs and manufactures subsea hot-tap fittings, diverless pipeline connectors, and subsea pipeline repair systems. Oceaneering International is involved in deepwater construction, ROV intervention, and ROV tooling. T.D. Williamson designs and manufactures hot-tapping equipment and provides hot-tapping services.

The feasibility study focused on two areas:

- Determining the steps necessary to complete a hot tap in deep water.

- Evaluating existing and state-of-the-art processes to determine if deepwater hot tapping would require all new technology or be able to rely on existing technology.

Some important areas of investigation included:

- Pipeline handling, lifting, and excavation.

- Pipeline cleaning and inspection.

- Hot-tap clamp deployment and installation requirements.

- Pressure testing.

- Hydrate remediation (gas).

- Hot-tapping machine and requirements.

- Operational requirements.

- Tie-in requirements.

Investigating each area established that existing technologies could be modified and brought together in a single package to realize a system to complete a diverless hot tap.

For example, Oil States had recently designed, manufactured, and tested several sizes of its diverless HydroClamp, a non-structural pipeline repair clamp used to seal a leak in a pipeline that is operated and installed completely by an ROV. In 1999, Oceaneering installed a 24-in. diverless HydroClamp in the Gulf of Mexico.

Oil States had pioneered the first diver-installed mechanical hot-tap clamp known as a HydroTap in 1971 and installed it in the Gulf of Mexico. The company felt that the diverless HydroClamp could be adapted to build a diverless HydroTap.

Oil States had designed and built ROV-operated pipe lift frames for part of a deepwater pipeline repair contingency program. One of these diverless pipe-lift frames was used to help recover a pipeline in 5,400 ft of water. Oceaneering had also installed 45 of these frames in the Gulf of Mexico to elevate a pipeline in 5,400 ft of water.

T. D. Williamson in 1971 had pioneered the first hydraulic mechanically operated subsea hot-tapping machine. Since then, the company has manufactured many subsea hot-tapping machines and felt it could adapt its design for deepwater use. This would entail using its latest design 1200 Series hot-tapping machine and developing an all new ROV-operable control system.

With Oceaneering's deepwater ROV operational experience, control systems could be developed for the hot-tapping machine. The company had developed ROV tooling which could be adapted to handle pipeline inspection and cleaning tasks.

Design, engineering

Three sizes of diverless hot-tap clamps were developed to provide an equipment design envelope during preliminary engineering. This allowed each participant to optimize as much equipment as possible.

Because of the size and weight of the individual pieces of equipment and an ROV's limited dexterity and maneuverability, much of the equipment was modularized.

In diver depths, it is common for the hot-tap clamp, ball valve, and hot-tapping machine to be joined before subsea deployment, and performing a horizontal tap is typical.

To optimize the tapping operation and future tie-in, designers determined a vertical orientation was preferable (Fig. 2a). This would reduce the loads on the tapping machine and allow for a vertical installation tie-in connector.

The hot-tap clamp could be deployed with the ball valve in a fitting-orientation frame without the hot-tapping machine. This would allow greater control, automation, and manipulation during installation by the ROV.

The fitting-orientation frame would also serve as an interface for other equipment (Fig. 2b). A tool-control module would be used to control the various pieces of equipment; it can be run and recovered as needed for each piece of equipment.

The hot-tap clamp is designed for installation with the split line in a vertical orientation for ease of installation over the pipe. The tool-control module (TCM) is deployed after the hot-tap clamp is landed over the pipe and actuates the stud tensioners on the hot-tap clamp body. The hot-tap clamp is tightened as it is rotated 90° to present an upward-looking hub.

The gripping and sealing elements are then actuated through the TCM. Following actuation of the grips and seals in the Diverless HydroTap, it is pressure tested to verify seal integrity. The fitting-orientation frame remains a permanent part of the subsea installation.

The hot-tapping machine was designed for use on a range of pipeline diameters with interchangeable cutter heads for the various branch sizes. The machine is attached via a flange to a collet connector. The collet connector functions as the connection point between the hot-tap machine and the diverless HydroTap.

The collet connector body also functions as the cutter can for the hot-tap hole saw. Following installation of the Diverless HydroTap, the hot-tapping machine is deployed and landed on the fitting-orientation frame. The TCM is connected to the hot-tapping machine and collet connector. The connector is made up to the hub on the ball valve. The ball valve can then be opened and system pressure tested again to verify seal integrity of all components.

Following a pressure test, the void space is flushed with glycol through the hot-tapping machine. The hot-tapping process is controlled through the TCM by controllers topside. After the hot tap is completed, the ball valve can be blocked in for flushing and removal of the hot-tapping machine.

Deep Tap equipment consists of the following:

- The fitting-orientation frame elevates the pipeline above the seafloor so that work can more easily progress, eliminating dredge work and discouraging debris from entering the pipe fitting. It supports the pipeline and the weight loads of the Diverless HydroTap and hot-tapping machine.

The fitting-orientation frame also functions as the interface docking point for the tool control module.

- The pipe lift frames are deployed first to lift and elevate the pipeline off of the seafloor. The pipeline must be lifted off of the seafloor to allow operations to be conducted by an ROV. These operations include inspection, cleaning, and manipulation. The pipe lift frames are completely ROV-operable and can raise a 20-in. pipe up to 60 in. (Fig. 3)

- The TCM is a central component in the installation tools for the diverless HydroTap. All hydraulic and control functions are to be controlled directly from the surface in the control van.

Subsea interfaces will connect the TCM with the fitting-orientation frame functions to manipulate, fasten, roll, and engage the diverless HydroTap. The TCM provides interfaces with the hot-tapping machine and the collet connector.

- The Diverless HydroTap is designed as a split clamp, which can be installed over a pipeline.

One half of the clamp contains a branch nozzle, which provides the tie-in point. A ball valve is welded to the branch nozzle, and a collet connector hub is welded to the ball valve.

To facilitate installation, the clamp is installed with the split line vertically oriented and the halves separated about 35° (Fig. 4).

The diverless HydroTap utilizes elastomeric seals to seal between the body halves and around the pipeline.

Longitudinal seal grooves machined into one half of the clamp are fitted with seals and form a pressure boundary when the clamp's halves are fastened together. Circumferential seals are installed inside the clamp halves and form the pressure boundary between the pipe and the HydroTap.

These seals are engaged when hydraulic actuators inside the clamp draw in a packing flange ring to compress the seals between the pipe and the Diverless HydroTap body. A patented ratcheting system mechanically locks the packing flanges in position to maintain proper compression on the seals at all times.

- The branch on the hot tap is fitted with a ball valve to provide an isolation control point during the tapping operation and for the branch line. The ball valve is welded to the diverless HydroTap and equipped with a collet connector hub. The connector hub allows for attachment of the hot-tapping machine and the tie-in jumper connector.

Manufactured by Cooper Cameron, the ball valve is designed for the service, maximum operating pressure, temperature, and water depth. Actuation of the valve is provided through a gearbox fitted with an API class torque bucket.

- The collet connector is a diverless connector used to make pressure-tight pipeline, wellhead, and manifold subsea connections. The purpose of the connector is to provide a pressure-tight connection between the diverless HydroTap and the hot-tapping machine.

The system contains a female and male hub, collets, drive ring, actuators, and alignment mechanisms. The connection is made by mating the two hubs and preloading them via collets. This action preloads the hubs and compresses a proprietary metal seal.

High preload between the collet connector male and female hubs enables the connector to support high external loads while maintaining the high integrity metal seal.

The connector incorporates an outer shroud structure to act as a guide funnel during initial make-up of the connector. Soft-land hydraulic cylinders allow the connector to be landed and lowered onto connection structure in a controlled manner. The soft-land cylinders dampen the impact of landing and allow the final end gap between the male and female hubs to be closed independently from heave motion of the construction vessel.

- T.D. Williamson's Deep Tap machine is a new generation machine that is remotely operated from the surface. The machine is mounted into a support and alignment frame to prepare it for subsea use. After the seawater is purged from the fitting, the ROV comes together with the machine and provides the hydraulic power and the electronic communication circuits required to operate and monitor the tapping machine.

A service technician operates and monitors the tapping machine from the surface using remote control . To assist the technician, the machine itself is designed to prevent cutter stalls through a self-adjusting, load sensing circuit to relieve the cutter feed rate during difficult tapping operations. A newly designed self-activating pilot is incorporated to ensure positive coupon retention during tapping operations.

The authors

Guy Suffridge is a commercial project developer for Williams Cos. Inc.'s deepwater systems group in Tulsa. He has 14 years' experience in the design and development of deepwater projects, pipelines, gas processing, and fractionation facilities. He holds a BS in chemical engineering from the University of Tulsa and is a registered professional engineer in Oklahoma.

Oran Tarlton is vice-president of engineering at Oil States HydroTech and has 23 years of subsea marine construction and engineering experience. Before joining Oil States, he was engineering manager at Big Inch Marine Systems and before that was a commercial diver and project manager with Cal Dive International and vice-president of Furmanite America Inc. Tarlton holds a BS in maritime systems engineering from Texas A&M University.