Equipment/Software/Literature

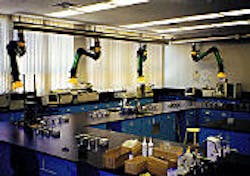

Extractor arms help remove smoke, dust, fumes

Now on the market is a range of 4, 6, and 8 in. diameter standard or stainless steel extractor arms designed to provide plant facilities with a noncorrosive, easily adjustable way to extract hazardous

materials such as welding smoke, dry dust, and acidic or caustic chemicals fumes. They provide acid resistance as well as washability.

Fume arms have no flow restriction inside the arm, which allows for clear and smooth movement of contaminated air and eliminates the possibility of any residue buildup. All of the adjustments

for the settings of the arm are easily accessed from the outside.

Each patented arm comes in a variety of standard production models with or without fans and filters or may be customized to suit any special application

Source: Oskar Antipollution, 8031 Jarry St. E., Montreal, Que., H1J 1H6.

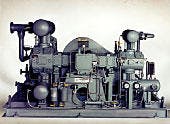

New line of on-site gas generation compressors

A new line of oil-free process piston and metal diaphragm gas compressors incorporates field-proved design features required for on-site gas generation.

These reciprocating gas compressors are suited for boosting the pressure of gases produced by most on-site methods. A range of preengineered configurations is available.

Units feature standardized packages that help reduce cost and lead-time, nonlubricated cylinder design that helps protect the purity of the gas, horizontally oriented cylinders for ease of maintenance and assurance against liquid accumulation, and water-cooled cylinders for temperature control. These standardized units are available in single-stage and multistage configurations with pulsation dampeners, process gas intercooler, and integral lube oil system with shaft-driven pump and oil filter. Options include lube oil cooler, aftercooler, and duplex oil filters. Remote monitoring of key parameters is available for unattended operations in critical services.

Typical on-site applications include nitrogen compression, hydrogen compression, argon compression, PSA or

VPSA generating systems, membrane separation systems, and cryogenic separations systems.

Source: Burton Corblin, 835 Wheeler Way, Langhorne, PA 19047.

Free vibration sensor brochure

A free, comprehensive brochure highlights accelerometers, vibration sensors, signal switching devices, and accessories for machine condition monitoring and predictive maintenance requirements.

Sensors for permanent installation and detailed analysis and diagnostics are featured as well as 4-20 ma transmitters for interface to process PLC, alarm, and SCADA systems. Also included are accelerometers with swivel mounting, high-temperature operation, and multiaxis measurement capabilities.

Source: PCB Piezotronics Inc., IMI Sensors Div., 3425 Walden Ave., Depew, NY 14043-2495.

Hydrogen sulfide gas detector

The new Model S4000T intelligent hydrogen sulfide gas detector is suited for chemical, oil and gas, and other hazardous environments. It features long distance remote mounting up to 3,700 ft, dual redundant modbus communications, 8 amp relays, three-digit display, 4-20 ma output, as well as indication of remaining sensor life.

The unit is a microprocessor-based intelligent transmitter designed for use with this firm's metal oxide semiconductor sensor. The unit features one person calibration and can virtually self-calibrate by activating a magnetic switch and applying gas. It is designed to detect hydrogen sulfide in ranges of 0-20, 0-50, and 0-100 ppm levels. It provides status indication, alarm outputs, fault codes for troubleshooting, and prompts when calibration is needed. All of the electronics are contained within an explosionproof housing so that sensor information can be processed at the sensor site. The 4-20 ma provides complete status to the control room.

The S4000T has four operating modes: 1) the normal operating mode in which alarms are active and the display and 4-20 ma readings are proportional to the gas concentration at the sensor; 2) the gas check mode that allows the user to apply a gas and check the sensor response while alarm outputs are inhibited; 3) a calibration mode in which gas is applied to the sensor to calibrate the unit; and 4) a setup mode that allows the user to review or change setup options such as relay settings, calibration levels and modbus parameters.

Source: General Monitors, 26776 Simpatica Circle, Lake Forest, CA 92630-8128.