Safety group pushes revised fire code for propane storage sites

US propane facilities with more than 4,000 gal on site would be required to prepare written fire-safety analyses under a revised Code for Liquefied Petroleum Gas published in April by the National Fire Protection Association (NFPA).

The nation's primary standard for propane safety, the code covers highway, marine, and pipeline transportation of LPG, plus containers, piping, and associated equipment for end users. States and municipalities often adopt NFPA codes into law, according to the National Propane Gas Association.

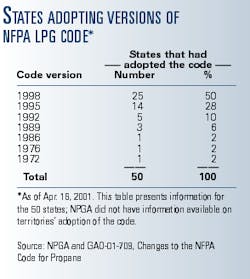

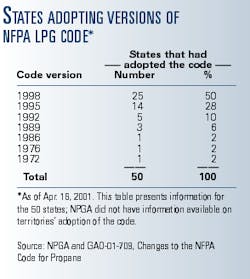

As of mid April, according to NPGA, 25 states had adopted a 1998 version of the code; remaining states had adopted earlier versions (see table). NFPA estimated 5-10 states will have adopted the new, 2001 code by yearend.

In 1999, the Chemical Safety Information, Site Security and Fuels Regulatory Relief Act exempted most propane facilities from the requirement to submit risk management plans to the US Environmental Protection Agency.

It further required GAO to report within 2 years on the status of revisions to the NFPA code regarding information for emergency personnel about the potential effects of accidental releases of propane to surrounding areas (so-called "off-site effects").

Published in July, the GAO report described revisions to the 1998 version of the code that were published in the latest version.

Stronger code

This version of the NFPA code, according to the GAO report, strengthens provisions of previous versions regarding information on the off-sites effects of accidental propane releases in four ways:

- The 2001 version provides that facilities' fire-safety planning should include consideration of the safety of emergency personnel, workers, and the public. The 1998 version provided for consideration of the safety of only emergency personnel.

- The revised code provides that facilities with more than 4,000 gal of propane on site evaluate their potential fire hazards and safety procedures and document them in a written fire-safety analysis.

Although the 1998 version required the fire-safety analysis for some facilities, it was not required to be in writing. - The 2001 version requires all propane facilities that meet the 4,000-gal criterion to prepare fire-safety analyses. By contrast, the 1998 version required only new (not existing) facilities meeting that criterion to prepare such analyses.

- An appendix in the 2001 version provides general guidance, recommending that propane facilities make their fire-safety analyses available to local emergency-response personnel to help them plan for and respond to propane accidents. The 1998 version contains no such guidance.

GAO reported that, to encourage revisions to the code, EPA participated in NFPA's consensus-based process.

Coverage

NPGA has said the NFPA LPG codes for 1998 and 2001 apply to propane systems such as the following:

- Containers, piping, and associated equipment used to deliver LPG to a building for use as a fuel gas.

- Highway transportation of LPG.

- Design, construction, installation, and operation of marine terminals whose primary purpose is the receipt of propane for delivery to transporters, distributors, or users.

The code does not apply to marine terminals associated with refineries, petrochemical plants, or gas plants. The codes also do not apply to marine terminals whose purpose is to deliver gas to marine vessels.

- Design, construction, installation, and operation of pipeline terminals that receive LPG from pipelines under the jurisdiction of the US Department of Transportation whose primary purpose is the receipt of LPG for delivery to transporters, distributors, or users.

Code coverage in these situations begins downstream of the last pipeline valve or tank manifold inlet.