In situ seismic shockwaves stimulate oil production

A new technology uses seismic pulses to mobilize oil left behind in reservoirs. Developed by Applied Seismic Research Inc. (ASR), Plano, Tex., the in situ seismic stimulation (ISS) creates elastic waves of high-energy (up to 10 Mw) and low-frequency that dislodge immobile oil droplets and coalesce oil films.

The ISS tool increased oil recovery by as much as 30%, as shown by production from wells in the Lost Hills field in California. In another trial in the Strawn sand in Texas, the tool improved the injectivity index of wells that were as far as 11/2 miles away from the well with the ISS tool.

Tool features

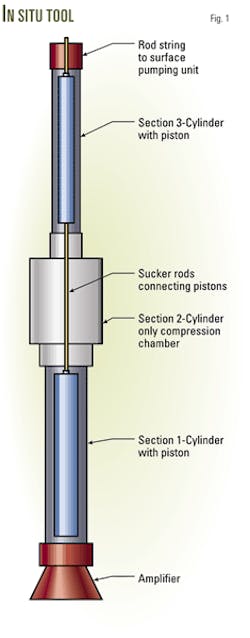

The ISS tool is similar to a tubing pump, powered at surface by a conventional pumping unit (Fig. 1). It can be installed at 800-7,000 ft depths, in wellbore IDs of 5.5 in. or greater. The tool is most effective if installed in active injection wells, but it can be placed in all types of wells.

ASR ships the tool, 180-200 ft in length when assembled, to location in sections of less than 30 ft each (Fig. 2). The tool is designed for continual service as a source of stimulation, with expected required replacement and maintenance comparable to a conventional tubing pump under similar wellbore conditions.

Currently ASR is making the tool available through a licensing program with a $17,500 initial fee plus $5,500/month for US applications. Foreign installation quotes also are available.

On every pumping cycle, the tool releases highly compressed wellbore fluids, creating seismic shockwaves. In an oil-bearing reservoir, the shockwaves propagate over long distances as high energy, low-frequency wave fields that in turn transform into localized high-frequency wave fields.1-3

Laboratory studies at the Los Alamos National Laboratory have demonstrated that low-frequency wave fields can mobilize immobile oil. And theoretical and experimental research performed at the Russian Academy of Sciences indicates that the localized high-frequency wave fields coalesce thin oil films into mobile oil droplets.

The key to the ISS tool's success, therefore, is to create high energy, low-frequency wave fields that propagate over long distances, which in turn become localized high-frequency wave fields.

The ISS tool has been tested in a wide range of oil reservoirs, having 0.0001-1 darcy permeabilities and oil specific gravities ranging from 17-38° API. The 17° API oil appears to be a lower limit for the tool, but an upper limit has not been established.

Typically, the tool is most effective in reservoirs having a relatively low GOR and a high degree of heterogeneity. The process does not appear to depend on reservoir rock type, depth, or wettability.

Vibrational waves

Vibrational wave use for improving formation permeability and fluid mobility is well-documented.2 4-11 Theoretical and experimental research shows that high energy, low-frequency (seismic) wave fields increase oil recovery and production in petroleum reservoirs.4 10 It was the application of these wave fields in situ that spurred development of the ISS tool.

Earthquakes, a natural source of high energy, low-frequency waves, have been observed to increase oil production as much as 45%.

Vibrational seismic or vibroseis developed in the late 1980s introduced a commercial source of high energy, low-frequency wave fields for, among other purposes, stimulating oil fields.2-4 8-10 Vibroseis equipment has a massive, 20-40 ton weight that repeatedly pounds the earth's surface.

Vibroseis has several disadvantages for being a source for stimulation. The first is that vibrations created at the surface attenuate as they pass through the different strata, so that the vibrations become considerably weaker by the time they reach their target. Thus, vibroseis has application only to relatively shallow reservoirs.

The second disadvantage is that a vibroseis truck is not simple to move around and requires enormous amounts of energy to operate.

Finally, as one could imagine, the vibroseis equipment tends to overheat after short periods of shaking a large mass and develops mechanical problems with continued use. Thus, continuous long-term, 1-2 months' use is neither possible nor plausible.

First generation tool

In the early 1990s, the Russian version of the ISS tool was developed and implemented in West Siberia oil fields.12

The device consisted of a tubing pump connected to several hundred feet of tubing, terminating in a stuffing box that sealed the system. Instead of pumping the fluids to surface, the tool compressed wellbore fluids within the tool between the pump and stuffing box. At the top of stroke of the pumping unit, the plunger exited the top of the pump barrel and released a moderately high-energy wave, on the order of 0.5 Mw.

The device had some disadvantages. It required a completely leak-free wellbore, a competent stuffing box that could maintain its seal under high-pressure cyclic loading, surface equipment to supply water to the system to overcome small leaks, constant monitoring, and adjustments at the wellsite.

In addition, the tool was limited to an 800-ft installation depth. Nevertheless, early stimulations were encouraging, increasing oil production by as much as 35-40%.

Typically, a tool stimulated an area continuously for a few weeks before being inactive for several weeks. This cycle was repeated a number of times.

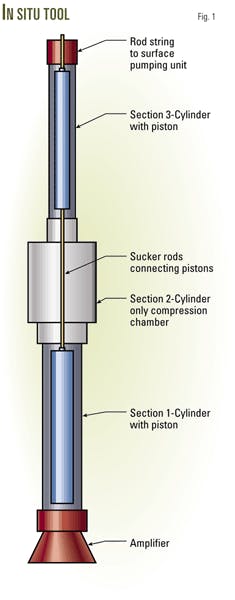

Fig. 3a shows that the Samotlor, West Siberia, oil field showed no immediate decline in production while the tool was operating at a 815-ft depth in an abandoned well. The field produces a 34° API oil with a 91% water cut from high quality sandstone with interbedded shales. The sand has a 100-2,000 md permeability, 21-29% porosity, and is at a 5,700-7,500 ft depth.

First US tests

In 1996, the first-generation tool arrived in the US. Although efforts were made to select good oil field candidates, stimulation results were short-lived and it became clear that tool maintenance would be a major obstacle to its widespread use.

A north-central Texas oil field provides a typical example of the first-generation tool's effectiveness (Fig. 3b). In the figure, the first five of six points in red indicate that the stimulation period lasted 5 months, and shortly after stimulation ceased, production returned to the projected decline, shown by the sixth red point.

The field produces a 34° API oil with a 96.5% water cut from the Strawn sandstone, having a 30-600 md permeability, 16% porosity, and a depth of 4,800-4,900 ft.

The tool was placed at a depth of 710 ft in an abandoned well.

Injectivity index changes for injection wells within a 1 1/2-mile radius of the well with the ISS tool indicated that during stimulation the injectivity index markedly increased. This indicated that the tool has the potential to improve overall fluid mobility and at large distances from the well in which it is installed.

It was not clear at that time why increases in oil production differed from stimulations performed in Russia (Fig. 3a), but it was clear that the tool improved fieldwide oil production and injectivity.

The tool, however, needed to be completely redesigned to be commercially viable for US oil fields.

Second generation tool

In January 1997, a dual tubing pump design eliminated the myriad problems associated with the first generation tool.13 14

The Kern River field in California, which produces heavy oil, was the test site for several versions of the tool.

The Kern River field produces an 11° API oil with and average 85% water cut from a sandstone formation with a 2,000-4,000 md permeability, 40% porosity, and a depth of 600-1,200 ft.

The tool was placed at about 704 ft in thermal observation wells.

ASR stimulated the field with the first-generation tool continuously for 3 months. During this time, a separate section of the field was also stimulated, albeit intermittently, with several design concepts of the second-generation tool. In both cases, no improvements in recovery were observed.

ASR's opinion was that heavy oil fields might not be good candidates for the tool, although the steam chests in the Kern River field may have been a factor. The chests considerably reduce the effectiveness of the ISS, and this may be significantly different in heavy oil fields that produce by gravity drainage or waterflooding,

A field producing from the San Andreas dolomite, a high porosity carbonate, on the eastern shelf of the Permian basin in Texas was the site of the next ISS trial.

This field produces a 28° API oil with an average 94% water cut from the San Andreas formation, having a 0.5-12 md permeability, 14% porosity, and a depth of 2,800-3,1000 ft. In the field, the tool was installed at a 2,506-ft depth in an injection well.

For the test, ASR tailored the second-generation design for an active injection well. The stimulation period lasted 11/2 months, first through third points in red in Fig. 3c. Initially, the group of 35 wells showed only marginal gains. Six months following stimulation, however, the oil-cut was about 23% better than expected.

Third generation tool

The diatomite reservoir in the Lost Hills field in California was the next stimulation of note. Before Lost Hills, it was becoming evident to ASR that ISS was independent of rock type and Lost Hills confirmed this. ASR believes the factors governing the success of ISS are reservoir structure, the presence of immobile oil, gas content, and oil density.

ASR designed the third-generation tool to operate in severely corrosive environments and the microbial induced corrosion found in Lost Hills injection wells provided an ideal environment in which to prove the design.

The Lost Hills oil field produces a 28° API oil with an average 70% water cut from the diatomite formation, having a 0.1-2 md permeability, 45-55% porosity, and a depth of 2,200-3,700 ft. The tool was placed at 812 ft in and injection well.

The tool stimulated the reservoir over 12 days in July and August and over 38 days in October and November.

For monitoring purposes, the operator provided a complete data set on 80 producing wells within a 1/2-mile radius of the injection well containing the ISS tool. To establish a control set of data, ASR screened these wells on the basis of well work and stimulations performed during the timeframe from January 1999 through March 2001. This resulted in a subset of 31 wells.

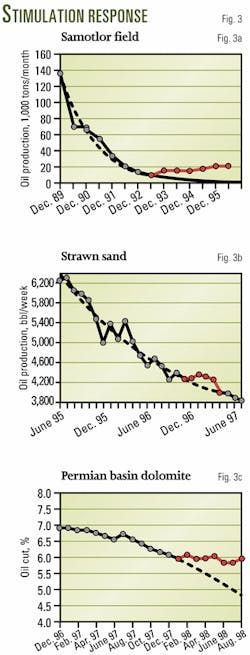

Analysis of the production indicated that for 26 wells (Fig. 4a) both oil cut and oil production increased significantly during September and October 1999. In light of the considerable evidence that earthquakes improve oil production, we wondered if these events would correlate to earthquake activity, common to California.

Using the US Geological Survey National Earthquake Information Center, World Data Center for Seismology in Denver, the University of California Berkley Seismology Laboratory, and the Xerox Palo Alto Research Center Map Server, we determined that from Sept. 10 through 26, a series of 4.6-4.9 events occurred 210 miles from the test field and on Oct. 16, a series of 5-7.1 earthquakes occurred 230 miles from the test field.

We also confirmed that no earthquakes rated 4 or greater were detectable within a 300-mile radius of our stimulation well during the ASR stimulation timeframe.

Based on an historical trend line developed from 19 months of production before July 2000, the 26-well group showed an average increase in oil cut of 32% and in oil production of 20%, as a result of ISS. The 26-well group represents 2,630 well tests or 3.6 well tests/well/month.

Analysis done 31/2 months after the stimulation showed both oil cut and production had returned to their previous trend lines.

The remaining five wells (Fig. 4b) did not respond to the earthquake events of September and October 1999. What is interesting and significant is that this group of five wells did not respond to ISS either. Investigation showed that the group of five wells lay to the southeast of the ISS tool site and the group of 26 to the northwest, indicating that in situ seismic stimulation is related to some degree to reservoir structure.

The operator suggested that the influence of other possible sources that could achieve such fieldwide changes, for example, changes in water injection needed to be identified and considered in the analysis.

To evaluate the influence of water injection on as many wells as possible, we expanded the control group to include all wells with historical data starting in January 1999. These wells included those that had stimulation and well work performed on them.

Fig. 4c represents this 48-well group consisting of 4,754 wells tests or 3.88 well tests/well/month. It is evident that during the earthquake events of September and October 1999 water injection for the field remained nearly constant; hence the earthquakes can be singled out as the cause of the observed effect. Similarly, the increased oil cut of 15% and oil production of 12%, observed during the 12-day stimulation of July and August 2000, are also during a stable water injection period.

Based on this analysis, we can state, therefore, that:

- There is a direct cause and effect relationship between in situ seismic stimulation and increases in oil cut and oil production, comparable to that of earthquake events.

- Increases in oil cut and production show that the ISS high energy, low-frequency elastic waves mobilize immobile oil.

All new wells in the Lost Hills diatomite require hydraulic fracturing to initiate production. It has been customary to refracture wells to revitalize well production and recovery. Fig. 4d shows a response of a group of seven wells. The colored sections of the plot show a baseline response, effects of the earthquakes of September-October 1999, the response to hydraulic refracturing during November-December 1999, and effects of the earthquakes and ISS.

The figure shows that:

- A single ISS tool increased oil recovery and production nearly as much as was achieved by seven fracturing jobs and that it did so at a fraction of the cost of even a single fracturing treatment in this field.

- ASR believes that for most reservoirs, ISS can essentially eliminate repeated hydraulic fracturing treatments, replacing them with a more efficient and less expensive field stimulation.

- Based on the subsequent in situ seismic stimulations, ASR estimated oil recovery in the 1/2-mile radius to have increased by at least 50,000 bbl.

ASR is planning additional ISS trials in the Lost Hills field.

Mechanisms that accurately model ISS's ability to mobilize immobile oil over large reservoir areas are at present not well defined; therefore, it is important to correlate ISS field results to core studies performed under controlled conditions.

Core studies

The Los Alamos National Laboratory detailed, bench-scale experiments investigated the effectiveness of low-frequency stress stimulation for enhancing the mobilization and transport of a dense-non-aqueous-phase liquid contaminant trapped in a water-saturated sand core.15

Although oil is lighter than water, the study showed behavior similar to some of the field stimulation data discussed previously. The experiment included sand packed into a rubber sleeve and confined radially and axially. After saturation with water, trichloroethylene (TCE) equivalent to 10% of the core pore volume was injected into the sand. The sand pack then had a mechanical stress stimulation in the axial direction at 25-100 hz frequencies and displacement amplitudes as high as 40 µm.

With a steady-state water flow initiated through the core, a gas chromatograph measured the effluent TCE concentration. At various stages of water flow, axial stress cycling was applied by mechanical coupling of a magnetostrictive actuator to the sand core's outlet face.

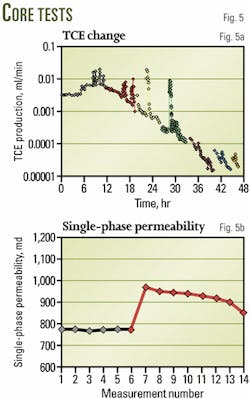

Fig. 5a shows the TCE production-rate results, in ml/min vs. cumulative time of constant water flow for the entire experiment. Axial stress stimulation caused all of the large production peaks.

During the first four runs, stress stimulation caused free-phase TCE droplets to be produced in the effluent and the net TCE production rate increased by a factor of 20 or more. TCE production remained high during stimulation and dropped back to low values shortly after turning off the actuator.

For the last four runs, when the background (unstimulated) TCE production had decreased to very low levels, stimulation continued to cause large increases in TCE production, but the enhancement tailed off quickly while stimulation was still being applied.

The test indicated that the largest production peaks occurred when the stimulation frequency was lower than 100 hz. The threshold for the stimulation source displacement amplitude, below which no significant TCE mobilization occurred, was about 12 mm. This produced an equivalent axial mechanical strain of roughly 20 microstrain and induced a pore pressure fluctuation of less than 70 Pa (0.01 psi) in the core sample.

Although the mechanical strain amplitude is relatively high, the simultaneous pore pressure fluctuations induced are extremely low. We believe the pore pressure changes are more important than the strain amplitude, and the ISS tool's success in the field may be related to its ability to introduce large fluid pressure pulsations into the formation.

Note also that the short-lived increases observed in the laboratory are similar to the oil production increases induced during the field test shown in Fig. 3a. This is possibly because stimulation directly mobilizes the non-aqueous liquid phase rather than inducing physical changes in the formation permeability. When the source is turned off, the fluids quickly return to their previous state as the dense-non-aqueous-phase liquid becomes trapped again.

Water flow alone, in the absence of stress stimulation, was unable to mobilize TCE even at flow rates as high as 1 pore volume/min. When the non-aqueous phase becomes trapped in the pore space, it cannot be significantly mobilized unless external forces directly affect the interfacial tension between the two liquids. This conclusion reflects the diminishing-returns behavior often observed during oil field waterflooding.

The test also showed long-term stimulated flow increases during a single-phase, core flow experiment using the same laboratory apparatus.16 17 A Berea sandstone sample, placed in the core holder, had its initial permeability estimated by measurement of the pressure drop across the core during steady-state flow of a 3% brine solution. The initial absolute permeability of the sample was 790 md. But while flowing brine, mechanical stress stimulation at 50 hz caused the permeability to increase by about 20%.

After the stimulation was turned off, the permeability gradually dropped to a level about 6% greater than the initial value over 24 hr (Fig. 4b). Subsequent experiments demonstrated that the increase was caused by mobilization of in situ clay particles (fines) partially plugging the pore throats of the Berea sample. This was done by briefly flowing fresh water through the core to liberate fines that are normally attached to the pore walls. This causes additional plugging of pore throats, resulting in a strong decrease in absolute permeability.

After establishment of a new base line permeability by flowing brine again, stimulation caused another 20% increase in permeability. Similar to the results in Fig. 4d, the increase gradually dropped again over 24 hr after the stimulation was turned off. This long-term behavior is similar to that observed during the ISS field tests shown in Figs. 1a, 3b, 4a, and 4b.

Previous laboratory experiments showed that fines mobilization also can be caused by ultrasonic stimulation at frequencies in the 20 khz range.18 The new experiments demonstrate that this effect also can occur at seismic frequencies of less than 100 hz.

Although no scientific evidence shows that the physical mechanism of fines mobilization causes long-term production increases in the field, the possibility cannot yet be ruled out. It is likely that numerous mechanisms are at play in any given reservoir and the relative dominance of one or more over others may determine if the effect will be short or long-term.

Certainly non-aqueous fluid mobilization must be considered as one of the more desirable mechanisms to target. At the core scale, this mechanism clearly causes short-term effects. If the ISS source can mobilize trapped oil over large regions of a reservoir, it could take a relatively long time for some of the mobilized oil to reach the production wells.

Depending on how far from the source the stimulation effect occurs, both long and short-term behavior could be observed in the field. Ongoing laboratory studies at Los Alamos are investigating various other physical effects such as pore wall fluid boundary-layer disruption, relative permeability changes, and inverted wettability, all of which appear to be influenced to varying degrees by low frequency, stress-wave or pore pressure fluctuations.

Acknowledgments

ASR gratefully acknowledges the interest and support provided by numerous companies in the testing of its designs during the course of the last 3 years of tool development. The Los Alamos National Laboratory experimental work was supported by the US Department of Energy, Office of Fossil Energy, through contract W-7405-ENG-36, and through internal discretionary funding from the Environmental Management Science and Technology Program Office through the Laboratory Directed Research and Development program.

References

- Dodd, R.K. et al., Solutions and Nonlinear Wave Equations. Academic Press, London, 1982.

- Nikolaevskiy, V.N., et al., "Residual Oil Reservoir Recovery with Seismic Vibrations," SPE Production & Facilities, No. 5, 1996, pp. 89-96.

- Nikolaevskiy, V.N., "Rock Vibration and Finite Oil Recovery from Reservoirs," Transactions (Doklady) USSR Academy of Sciences, No. 5, 1992, pp. 110-19.

- Beresnev, I.A., Johnson, P.A., "Elastic-Wave Stimulation of Oil Production: a Review of Methods and Results. Geophysics," Vol. 59, No. 6, 1994, pp. 1000-17.

- Ganiev, R.F., Oukrainsky, L.E., and Frolov, K.V., "Wave mechanism of fluid acceleration in capillaries and porous media," Transactions (Doklady), USSR Academy of Sciences, Vol. 306, No. 4, 1989, pp. 803-06.

- Ganiev, R.F., Kostrov S.A., Oukrainsky L.E., Wave Technology, Logos, Moscow, 1993, pp. 49-58.

- Kuznetsov, O.L., and Efimova, S.A., Application of Ultrasound in Oil Industry, Nedra, 1983.

- Kuris, A., Method and System for Ultrasonic Oil Recovery, US Patent, No 3990512, November 1976.

- Kurlenya, M.V., and Serdyukov, S.V., "Reaction of Fluids of an Oil Producing Stratum to the Low Intensity Vibro-Seismic Action," Journal of Mining Science, Vol. 35, No. 2, 1999, pp. 113-19.

- Nikolaevskiy, V.N., "Mechanism of Vibroaction for Oil Recovery from Reservoir and Domain Frequencies," Transactions (Doklady), USSR Academy of Sciences, Vol. 307, No 3, 1989, pp. 570-75.

- Pogosyan, A.B. et al., "Segregation of Hydrocarbon Fluid and Water in Porous Medium Elastic Wave Field, Transactions (Doklady), USSR Academy of Sciences, Vol. 307, No. 3, 1989, pp. 575-77.

- Vagin, V.P., Method and Apparatus for Shock Wave Stimulation of Oil-Bearing Formations, US Patent 5,586,602, Dec. 24, 1996.

- Kostrov, S.A., Dual Tubing Pump for Stimulation of the Oil-bearing Formation, US Patent No.6015010, January 2000.

- Krylov, A.L., and Nikolaevskiy, V.N., "Mathematical Model of Non-linear Generation of Ultrasound by Seismic Waves," Transactions (Doklady), USSR Academy of Sciences, Vol. 318, No. 6, 1991, pp. 1339-45.

- Roberts, P.M., Sharma, A., Uddameri,V., Monagle, M., Dale D.E., and Steck, L.K., "Enhanced DNAPL Transport in a Sand Core during Dynamic Stress Stimulation," Environmental Engineering Science, Vol. 18, No. 2, 2001, pp. 67-79.

- Roberts, P.M. and Sharma, A., "Low-Frequency Acoustic Stimulation of Fluid Flow in Porous Media," Journal of Acoustic Society of America, Vol. 105, No. 2, Part 2, 1999, p. 1385.

- Sharma, A. and Roberts, P.M., "Seismic Stimulation of Oil Production in Mature Reservoirs," AAPG Annual Convention, extended abstracts, Vol. 2, 1998, p. A591.

- Venkitaraman, A., Roberts, P.M., and Sharma, M.M., "Ultrasonic Removal of Near-Wellbore Damage Caused by Fines and Mud Solids," SPE Drilling & Completion, Vol. 10, No. 3, 1995, p. 193.

The authors

Sergey A. Kostrov is technical director for Applied Seismic Research Inc., Plano, Tex. He has been involved with theoretical and experimental investigations into the affect of elastic waves on mass-transfer processes in multiphase media. Kostrov holds an MS in mechanics of high-speed processes from Moscow State Technical University and PhD in fluid mechanics from the Mechanical Research Institute of the Russian Academy of Sciences. He is a fellow of the Russian Academy of Sciences, Moscow.

William O. Wooden is vice-president of Applied Seismic Research Inc., Plano, Tex. He has a background in sales and marketing of emerging technology. Wooden has a BS in sciences and engineering from the University of Oklahoma.

Peter Morse Roberts is technical staff member, project leader, at the Los Alamos National Laboratory, NM. His current research interests are seismic stimulation of fluid flow in porous media, laboratory and field experimental acoustics and seismology, 3D exploration imaging, teleseismic tomography, and wavefield modeling. Roberts received a BS in biology and a PhD in geophysics, both at the Massachusetts Institute of Technology.