Expandable liner saves casing string in Oman well

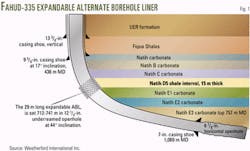

Petroleum Development Oman LLC (PDO) installed a 29-m section of alternative borehole liner (ABL) in the Fahud-335 well, 276 m below the 95/8-in. casing shoe, selectively isolating a problematic shale interval (Fig. 1).

Weatherford International Inc., Houston, which supplied and ran the liner, said in a July press release that the installation was a world-record and that its previous record for setting an ABL was 56 m below the casing shoe.

PDO installed the ABL in a 121/4-in. underreamed section of the open hole across the interval 712-741 m MD at 44° hole angle, covering the 15-m thick shale formation.

Before expansion, the ABL was 65/8-in. OD. Crews expanded the liner (81/2-in. ID, 91/4-in. OD) within the 121/4-in. underreamed section of the open hole and then filled the annulus between the expanded liner and open hole with cement.

After installing the ABL across the problematic shale, PDO drilled the remaining 380 m of 81/2-in. hole to TD. Crews then ran the 7-in. liner through the ABL and cemented it successfully.

The ABL system allows operators selectively to isolate problematic formation intervals in a wellbore without loss of hole size. Unlike conventional casing or liner strings, the ABL isolates specific problem formations, rather than the entire section back to the previous casing shoe.

Crews set the ABL on drill pipe using a totally mechanical setting procedure, allowing it to be set in any hole condition, including underbalanced or with the well on vacuum.

Although the build rate of the open hole setting location in Fahud-335 was not reported, Weatherford's running procedures state that the ABL can be set in a wellbore with a maximum build rate of 15°/100 ft. The cement job for the ABL can be performed before or after the liner expansion, depending on the differential pressure across the ABL while pumping the slurry and on other details of the specific application, according to Weatherford's running procedures.

The ABL cement recipe is essentially the same as the conventional cement recipe for the well's previous casing string, however, Weatherford recommends using fiber 0.25-0.5 wt % cement.

Fiber cement is tougher, compared to neat cement, providing higher impact strength and longer-term durability. Fiber cement also maintains mechanical integrity during bottom-hole assembly trips and ensures pressure integrity during pressure cycling. With this installation, Weatherford says it has run 65 expandable liners including 18 installations of the ABL.