Equipment/Software/Literature

Flowmeter series is HART bus compatible

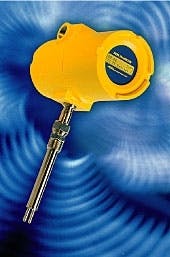

Process and plant engineers who need an accurate, repeatable flow measurement tool can use the FlexMASSter ST98 flowmeter series, which now combines performance with digital communications flexibility, thanks to the recent addition of HART bus compatible electronics.

Suited for petrochemical plants and other processing operations, the ST98 helps enhance flow measurement data handling and overall control system flexibility, the company says. HART, or highway addressable remote transducer, superimposes a digital signal on top of the standard 4-20 ma analog signal, offering expanded intelligence that is suited for commissioning, diagnostics, and maintenance.

The flowmeter's thermal mass sensing element delivers precision measurement over a wide flow range. It features an accuracy of ±1% of reading plus ±0.5% of full scale. It has a repeatability of ±0.5% of reading.

The unit's packaging design allows easy access to termination points and communication ports; the flowmeter comes in integral and remote configurations. It is available in two classes of enclosure. One is weather resistant, the second is weather resistant and explosionproof, meeting standards for hazardous location use. Both enclosures are designed to resist corrosion. An RS-232C serial port interfaces with this firm's FC88 Communicator, with a remote computer, or with any ASCII terminal. Standard output is 4-20 ma.

The sensing element consists of two all-welded 316 stainless steel thermowells that protect resistance temperature detectors (RTDs). One RTD is heated relative to the reference RTD, and the temperature difference between the two is related to the process mass flow rate. The standard flow elements have adjustable insertion lengths and are available in sizes of 1-6 in., 1-12 in., and 1-21 in. The process connection is a 3/4 in. NPT or flanged compression fitting, with a Teflon or stainless steel ferrule.

Source: Fluid Components International, 1755 La Costa Meadows Drive, San Marcos, CA 92069.

Catalog discusses pipe cutting, beveling machines

A new 114 page catalog, yours free for the asking, focuses on pipe cutting and beveling machines. It also discusses pipe alignment and reforming clamps, welding electrode and flux ovens, and a variety of pipefitter's tools.

Source: Mathey Dearman Inc., 4344 S. Maybelle Ave., Tulsa, OK 74107.

New transducer can work in hazardous locations

Here's the Type 950 explosionproof I/P (current-to-pressure) transducer.

It's designed to deliver reliable high performance for uses in hazardous environments.

It converts an electrical current signal to a proportionally linear pneumatic output to actuate valves. Its NEMA 4X (IP65) housing is designed for intrinsically safe and explosionproof operation. It has Factory Mutual, Canadian Standards Association, and Cenelec (European) approvals for explosionproof applications. Advanced circuitry includes electronic feedback control for vibration protection and accurate output.

In addition to accuracy of 0.10%, the 950XP also delivers low hysteresis and excellent repeatability, the firm says. The 950XP is able to process impure air thus reducing downtime. Easy access zero and span adjustments help make bench or field calibration quick and easy.

Options include direct, reverse, and split range modes. A piezoelectric bimorph actuator and surface-mounted electronics are conveniently mounted on a removable control manifold that allows easy maintenance.

The transducer has a built-in volume booster that provides up to 10 scfm airflow capacity to drive large valves, cylinders, and actuators. The unit utilizes an input signal of 4-20 ma and has field-selectable output ranges of 3-15 psig, 3-27 psig, 6-30 psig, and 1-17 psig. Supply pressures range up to 100 psig. The standard mounting bracket allows mounting directly on a valve, wall, panel, or pipe. The unit is insensitive to position, vibration, supply pressure variation, and RMI/EFI interference.

Source: ControlAir Inc., 8 Columbia Drive, Amherst, NH 03031.

Free 200 page PC systems handbook

The new, free, 200 page PC Systems Handbook for Scientists and Engineers features hard-to-find industrial computing, data acquisition, and motion control systems and components.

Comparison charts highlight critical information engineers can use. As an example, one chart takes 6 pages, comparing 51 specs for more than 160 analog-input boards.

You may e-mail your request for the free handbook to [email protected].

Source: CyberResearch Inc., Box 9565, New Haven, CT 06535-0565.