Equipment/Software/Literature

Units supply nitrogen purge gas offshore

New Models IB300-X and IB500-X membrane nitrogen systems produce nitrogen purge gas in hazardous marine locations.

Each one:

- Is all stainless steel (less compressor) for offshore installation.

- Is designed for operation in an NFPA 70, Class 1, Division 2, Groups C and D hazardous location (with Z-purge panel purging system).

- Features customer feed air or optional Sullair oil flooded rotary screw air compressor (175 psig discharge).

- Includes primary and secondary feed air filtration, superheater, and carbon trap to help protect the membrane cartridges.

- Includes oxygen analyzer with automatic pipeline isolation if product nitrogen purity is below set point.

Source: Praxair Inc., 64 Craycroft Ave., De Bary, FL 32713.

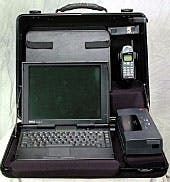

Portable lap top work site

A new lap top work station for the outside sales, engineering, and service oilman is on the market.

Components are hooked up through the custom built-in power strip and surge protector. Field personnel will be fully operational anywhere there is an electrical outlet, even in the car. If an emergency occurs at a field site or in a refinery, the lap top work station provides the engineer the capability of being immediately operational to transmit reports, analysis, and data to the office.

Sales engineers can e-mail immediate quotes to clients from their car. Sales and marketing persons can make numerous lengthy presentations without worrying about batteries being drained, the firm points out. At trade shows and conventions, sales orders and communications can be immediately sent back to the home office in minimal time, the company says.

The durable hard shell ballistic nylon case exterior and interior insulation protect sensitive equipment. It can work with satellite phones in remote areas, GSM phones in over 120 countries, and all US cellular phone products. Any kind of phone can be hooked up to your lap top computer and your printer/scanner. All equipment can be recharged with the case open or closed through an outer access port. Its dimensions of 19 by 15 by 6 in. meet all airline carry-on requirements, the company says.

Source: J.M. Precision Inc., 9722 Topanga Canyon Blvd., Chatsworth, CA 91311.

Fiber optic tank gauging system

The new HP/MD Series fiber optic tank gauging system promises a safe, economical solution for a range of liquid level applications.

The HP/MD visible laser system consists of a top-mounted, stainless steel-housed, optical sensor head; a NEMA 4X optical connection box mounted near the tank base; and a battery-operated, portable reader unit. The system's connection box and sensor heads contain no electronic components and require no power source. Additionally, the sealed sensor heads are impervious to most harsh environmental conditions, and can be quickly and easily removed for cleaning, the company notes.

The system is specifically designed for fast, easy operation. To inventory a tank, the user connects the reader unit to the optical sensor head via detachable connector, enters the appropriate tank identification number, and retrieves the level measurement data. A single reader unit can capture inventory information for as many as 50 tanks or sensor heads. These data are downloadable directly to a PC or viewable on the reader unit's display.

Source: Phase Laser Systems Inc., 14255 N. 79th St., Suite 6, Scottsdale, AZ 85260.

Unit produces precise calibration gas mixtures

The Span Pac I industrial standards generator uses a Trace Source permeation tube to produce precise calibration gas mixtures. Concentrations from low ppb to over 1,000 ppm are generated directly from the pure component. There is no interstage mixture required.

It is easy to use, safe, and specifically designed for field mounting with process analyzers. The unit can be operated from a remote station and is housed in a NEMA 4 specification cabinet for N.E.C. Class 1, Group C or D, Div. II hazardous atmospheres. An X-Purge option adapts it to Div. I service. Models providing single or multicomponent capability, and a variety of operational features, are available.

Applications include ppb CO and COS in propylene, VOCs NOx, H2S, S02, Cl2, HCL, and ppb BPX in air. The permeation tubes are available for more than 200 vapors, including most industrial toxicants.

Source: Kin-Tek Laboratories Inc., 504 Laurel, La Marque, TX 77568.