Multiphase measuring advances continue

The number of multiphase metering installations has increased as industry continues to advance this technology that measures oil, water, and gas quantities in flow streams without the need to separate out individual phase components.

This article reviews various applications of this technology and summarizes the results of a survey that counted the worldwide multiphase metering installations in operation.

Flow measurement

Oil, water, and gas flow rate measurements from wells allow a production operator to manage a reservoir and allocate production. Currently, operators still obtain these measurements mostly with conventional gravity-based test separators that separate the flow stream into oil, water, and gas. Each phase is then measured with a single phase, flow measurement device.

This approach works well when the stream components can be easily and fully separated.

When the production stream contains tight emulsion or foaming, however, the conventional approach produces a large uncertainty in the measurement.

Furthermore, the well test cost increases substantially if an operator needs to introduce emulsion or foam-breaking chemicals or must manually sample the water cut in the liquid stream.

Offshore operators were the first to look at multiphase metering as a technology that could reduce bulky and heavy conventional test separators on platforms. Their interest led operators and meter vendors to develop and field-test a variety of multiphase meters.

Mehdizadeh reviewed the performance of these various multiphase metering techniques and discussed the evolution of multiphase metering and attempts by operators to establish the capabilities of this technology.1-3

Multiphase meter installations

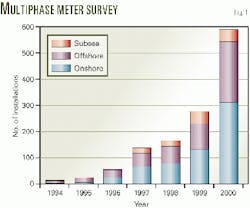

Fig. 1 shows the trend in the number of multiphase meter installations, based on the author's annual survey. The number has steadily increased since 1994, and in the last 2 years has grown substantially.

Currently, about 600 multiphase meter installations are in various operations in the world. While this number is a small fraction of the total number of well test sites, the rate of growth has been substantial and widespread.

The initial interest in the technology was confined to offshore and subsea applications, but now more than half of the installations are in onshore operations (Fig. 1).

Onshore operators use multiphase meters to reduce the well test costs by reducing a well's test time to 1-2 hr. The short test time allows an operator to test more wells per day with multiphase meters than with conventional test separators.

These shorter times especially are important for reducing the cost of operating marginal onshore reservoirs.

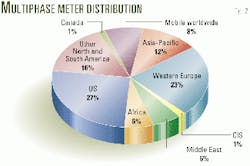

Another trend is that this technology is being used by a wider assortment of operators. Major operators in the North Sea initially were the main users, but the current distribution of the installations (Fig. 2) indicates that the technology is becoming more accepted and used by operators within all production regions.

Two major factors have contributed to the wider spread use of this technology.

First, development of efficient compact separators has made available lower cost off-line multiphase metering systems.4

In contrast to the in-line multiphase meters, which accept the full stream, the off-line systems temporarily remove gas from the flow stream. The gas and liquid streams are then measured separately before being recombined into the initial full stream.

The off-line multiphase metering systems are less complex and costly but offer some, if not all, the advantages of the in-line multiphase measurement systems, which include real time measurement, shorter test times, and smaller equipment size and weight.

Off-line applications are limited to fluid streams where gas and liquid can be separated easily.

These systems account for about 40% of the current installations.

The off-line separation-based multiphase metering systems may be particularly suitable in operations where high water cut impacts the accuracy of the hydrocarbon determination.5

Fig. 3 shows an off-line type of multiphase meter in an offshore installation. This fairly compact unit is capable of handling 7,500 b/d of liquid and 6 MMscfd of gas.

Secondly, the compact size of multiphase meters has resulted in the deployment of mobile systems (Fig. 4). These systems enable operators to use multiphase metering in remote regions or in operations where a conventional well test facility would be unavailable.

Trailer-mounted multiphase meters (Fig. 5) reduce the cost and improve the quality of well tests in fields where wells are scattered over a large area.6 In the past 3 years, the number of mobile systems has increased significantly and now accounts for about 20% of the multiphase metering installations.

Application trends

Research on multiphase metering has provided a number of systems with different capabilities and costs that are being installed in assorted production operations.1

Operators initially justified North Sea installations on the basis of smaller equipment size and weight as well as reduced cost of subsea projects.2 In early field trials, operators discovered that online capability of multiphase meters could decrease the well testing time.

The more-costly multiphase metering equipment, therefore, could be justified because it allowed the operator to test more wells, more frequently, with more consistent accuracy.

Furthermore, multiphase meters could reduce operator intervention in some op erations.

These factors helped reduce the overall well test cost and produced better quality well test data.5 6 The real-time flow measurement capability of multiphase metering has afforded operators use of the system as a diagnostic tool for production optimization and flow assurance.3 7 8

In a new trend, operators are including multiphase meters in exploration well testing. This application allows exploration well test flow to be analyzed in real time.

In the past, well performance measurements were limited by off-line data from conventional gravity separation technology.

The real-time flow data from multiphase metering improves the flow-rate history for transient analysis.9 In addition, flow-rate data can be acquired at surface pressures above the operating limit of a test separator, thus broadening the well test operating envelope.

Technology trends

Industry is continuing its search for better and cost effective techniques for nonintrusive multiphase metering, such as field tests on novel gas-liquid flow and fraction measurements based on pressure fluctuation and flow pattern recognition using neural network.10 11

Field tests also have been conducted on a downhole multiphase flow meter that uses sonic measurements to determine the gas-liquid fraction and a cross-correlation technique for flow rate measurements.

One collateral benefit of the search for developing multiphase measurements is the availability of improved oil-water monitoring devices, referred to as OWMD.13 These devices retrofitted to a conventional gravity test separator can replace frequent manual water-cut sampling, thus, increasing water-cut accuracy and reducing operating cost.

One can determine accurate total oil and water flow with a flow computer that incorporates the online continuous water-cut data, from the OWMD, with liquid flow meter data.

With this arrangement, one operator measured net oil in a commingled production facility, where produced fluids from several smaller leases were commingled in a large central dehydration facility.14

The current trend of using multiphase measurement techniques in production and exploration well testing indicates that the technology has matured and is being accepted by many operators. For instance, Schlumberger Inc. is offering exploration well testing services using a multiphase metering system.

Some operators have been reluctant to use these meters because of the high cost associated with new technology. But as the number of applications increases and more products enter the market, the industry will inevitably see a reduction in cost.

But there are ample examples of a variety of current applications where operators have been able to justify the use of multiphase metering on the basis of cost benefit analysis.

This should give encouragement to those users who have been standing on the sideline to exploit this technology to improve well testing and production measurements, which has a major impact on the reservoir management.

References

- Mehdizadeh, P., "Multiphase Meters: Delivering Improved Production Measurements and Well Testing Today," Petroleum Engineering International, May 1998.

- Mehdizadeh, P., "Off-Shore, On-line, The evolution of multiphase metering," Offshore International, Summer 1999.

- Mehdizadeh, P., "Optimize Production with Online Measurements," Hart's E&P, November 1999.

- Shoham, O., and Mohan, R., "Integrated Compact Separation Systems for the Petroleum Industry of the New Millennium," ASME ETCE Workshop, Feb. 5-7, 2001.

- Marrelli, J., "Optimal matching of separation and metering facilities for performance, cost, and size," Energy Sources Technology Conference & Exhibition, New Orleans, Feb. 14-17, 2000.

- Means, S.R., and Mehdizadeh, P., "New technology improves well testing units" OGJ, Oct. 30, 2000.

- Ngai, C.C., Brown, M.D., and Mehdizadeh, P., "Performance Test of a High Gas Volume fraction Multiphase Meter in a Producing Field," SPE Paper No. 38784, SPE Annual Technical Conference & Exhibition, San Antonio, 1997.

- Theuvney, B.C., Segeral, G., and Moskens, P., "Detection and identification of Scales Using Dual Energy/Venturi Multiphase Flowmeters" OTC Paper No. 13152, OTC, Houston, 2001.

- Mus, E.A., Toskey, E.D., Bascoul, S.J.F., and Norris, R. J., "Added value of a multiphase flow meter in exploration well testing," OTC Paper No. 13146, OTC, Houston, 2001.

- Toma, P., and Ridley, R., "Development and testing of a novel gas-liquid flowmeter combining pressure fluctuations generated by vertical and horizontal flow patterns," Second North American Conference on Multiphase Technology, Banff, Canada, June 21-23, 2000.

- Toral, H., Cai, S., and Akartuna, E., 'Multiphase flow rate identification by pattern recognition at Shell Auk platform," 18th North Sea Flow Measurement Workshop, 2000.

- Gysling, D.L., Vandeweijer, T., and Van der Spek, A., "Development of a Permanent Downhloe Two Phase Flow Meter," SRI Multiphase Metering and Pumping Conference, February 2000, Houston.

- Mehdizadeh, P., "Better Net Oil Monitoring," Hart's E&P, August 2000.

- Mehdizadeh, P., "Test Verifies Water-Cut Meter Accuracy in Steam flood," OGJ, Oct. 2, 2000.

The author

Parviz Mehdizadeh is a consultant with Production Technology, Phoenix, Ariz. He previously worked for Conoco Inc. and Agar Corp. Mehdizadeh holds a BS and MS in physics and a PhD in chemical engineering and materials sciences from the University of Oklahoma. He is a member of SPE and has served on various API standardization committees.