Africa in Perspective: Deepwater West Africa development accelerates

This is the concluding article of a three part series of OGJ Tech nology Insights on deepwater technology challenges. The first (OGJ, May 1, 2000, p. 87.) covered the Gulf of Mexico and the second (OGJ, Sept. 11, 2000, p. 90) dealt with deepwater technology off Brazil.

Floating production, storage, and offloading (FPSO) vessels tied to subsea wellheads or dry-tree platforms, such as spars and tension leg platforms, are slated to handle most of the fluids produced from the numerous deepwater discoveries off West Africa.

The expected investment in West Africa deepwater is large and increasing. Douglas-Westwood Ltd. has estimated investment in deepwater West Africa will increase to $5.5 billion in 2004 from the $1.9 billion spent in 2001 for platforms, wells, trees, templates and manifolds, controls, control lines, and flowlines.

Most West Africa deepwater development projects target oil recovery. In a February 2001 study, the International Maritime Association Inc. listed 8 West Africa deepwater projects in the bid or design stage and 26 that are at a planning or study stage (Table 1).

Gas potential

Although in many West Africa deepwater oil developments gas likely will be reinjected, some operators have proposed plans to market the gas. For instance, Shell Petroleum Development Co. (SPDC) has plans for an associated gas pipeline system off Nigeria that will gather gas from its deepwater Bonga field and other potential deepwater discovers and deliver the gas to the Nigeria Liquefied Natural Gas Co. LNG facility at Bonny, Nigeria.

Liquefying natural gas for export is also being considered for gas production off Angola. In this regard, Texaco Inc. has announce plans for appraisal drilling off Angola in 2001 to evaluate gas reserves on three deepwater blocks, Blocks 15, 17, and 18.

The gas, along with associated gas from shallow production, would go to an LNG plant built in a joint venture with the state oil company Sonangol. Texaco estimates that first LNG cargoes could be shipped in mid-2005, if the project is finalized.

Another proposal, put forth by Vanco Energy Co., would build a gas pipeline from West Africa to Europe. Its proposal includes first laying the pipe to potential gas fields off Morocco and then in a phased construction continuing the pipeline to the south.

Vanco says large proven gas and associated gas reserves exist off the Ivory Coast, Ghana, Benin, Nigeria, Cameroon, Gabon, Congo (Brazzaville), Congo (former Zaire), Angola, Namibia, and South Africa.

Development features

Four projects, Kuito, Ceiba, Girassol, and Bonga, illustrate some of technology involved in developing deepwater oil fields off West Africa.

One common feature of these four projects is that all have spread moored FPSO systems instead of the heavier turret type systems. The lighter mooring is viable off West Africa because environmental conditions are milder than off Brazil or in the Gulf of Mexico, the two other main regions with deepwater discovers (OGJ, May 1, 2000, p. 86).

For instance, wind speed off Africa averages 25 m/sec compared to 42 m/sec in the Gulf of Mexico and 35.4 m/sec off Brazil, and maximum wave height is only 7.1 m compared to 23.2 m in the Gulf of Mexico and 14.5 m off Brazil.

Operators off West Africa, unlike those in the Gulf of Mexico, also do not have to worry about hurricanes.

Kuito field

The development of Kuito field, Block 14 off Angola, is in its third phase. Chevron Corp. unit Cabinda Gulf Oil Co. (CABGOC) operates the field, which lies in 1,300-ft water.

Kuito was the first deepwater field put in production in Angola, with first oil starting to flow in 1999.

The initial development phase included a 12-slot subsea production manifold and a remote gas injection well with the crude oil being produced to a 229,000-dwt FPSO vessel through a riser porch (Fig. 1).

The 335 m by 44 m by 28-m FPSO can store 1.4 million bbl of oil, and has facilities that are designed for processing 100,000 bo/d, 20,000 bw/d, 10 MMcfd of gas, and injecting 110,000 bw/d.

The latest development phase adds a subsea production center with seven wells producing through a 12-slot manifold and an additional four water injection wells at the existing water injection center connected to the FPSO.

Partners in the field are CABGOC, 31%, Sonangol, 20%, ENI SPA unit Agip, 20%, TotalFinaElf SA, 20%, and Petrogal, 9%.

The field produces with a 200 scf/bbl GOR, and CABGOC designed a subsurface gas-lift system for the life of the well to eliminate well intervention costs and the need to flare gas.

Ceiba

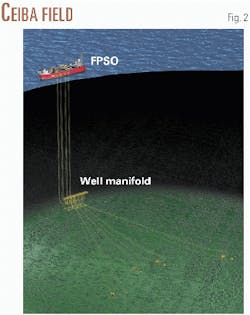

Triton Energy Ltd. developed the Ceiba field, Block G, off Equatorial Guinea as a fast-track project that allowed it to start producing oil within 14 months of the field's discovery. To achieve the fast start up, Triton went to a spread moored FPSO converted from a 275,000 dwt tanker, measuring 1,150 ft by 170 ft and having the capacity to store 2 million bbl of crude.

The field is in 2,400 ft of water, although the FPSO is moored in shallower 300 ft of water.

Triton has an 85% working interest in the field with the remaining 15% being held by Energy Africa Ltd. of South Africa.

The initial oil and gas processing facility provides a processing capacity of 60,000 b/d, but Triton initially planned on the possibility of additional production modules that could increase the combined capacity to 240,000 b/d, if necessary.

Recently Triton reported that it planning to replace the Ceiba FPSO with a similar sister ship with expanded processing facilities. Triton says the upgraded vessel would have a 160,000-b/d liquids processing capacity and facilities for injecting 135,000 b/d of water for pressure maintenance.

"By performing the upgrade in a controlled shipyard environment, Triton expects to accomplish the expansion more cost effectively and efficiently and with less operational risk than if the additional equipment were installed on the existing vessel offshore under producing conditions," the company said.

Triton installed 5 in. by 2 in., 5,000-psi horizontal trees on each of the initial four producing wells. Each well is tied back to individual, retrievable subsea manifolds (Fig. 3) that tie each tree to two export lines. The manifold contains interfaces for subsea installation of the flowline connections, production jumper, and the pigging loop. A single pile supports the manifold.

The subsea system has electro-hydraulic controls.

To connect the first four production wells to the FPSO vessel and a riser support structure required about 60 km of 8-in. insulated steel flowlines, 2.8 km of flexible risers, and 30 km of control umbilicals. Each well has two flowlines for production and operational flexibility.

The second phase of the Ceiba development calls for 14 wells to be drilled and completed at the field-10 producers and 4 water injectors by early 2002.

Girassol

The Girassol field development (Fig. 4) includes the world's largest FPSO (Fig. 5) according to operator TotalFinaElf. It plans to have the vessel on location (Block 17 off Angola) in July 2001, with first oil starting to flow at year-end 2001. It discovered the field in 1996.

Partners in the development include TotalFinaElf, 40%, ExxonMobil Corp., 20%, BP PLC, 16.67%, Statoil, 13.33%, and Norsk Hydro AS, 10%.

The 50,000-tonne FPSO hull supports a 23,500-tonne topsides that processes 200,000 bo/d, treats 300,000 b/d of fluid, and injects back into the reservoir 390,000 bw/d and 8 MMcfd of gas. The 300 m by 60 m by 31-m FPSO has a 2 million bbl storage capacity and will be spread moored in about 4,600 ft of water.

The topsides processing facility features the largest desulfurization unit in the world, allowing treatment of 390,000 b/d of seawater for water injection, according to TotalFinaElf.

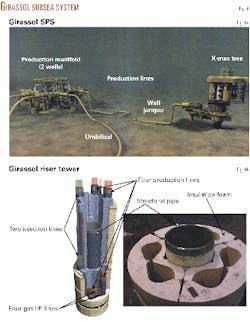

The development scheme includes 23 producing wells, 14 water injection wells, 3 gas injection wells, five 8-in. production loops with a pigging system, and five 10-in. injection lines.

TotalFinaElf expects to produce up to 40,000 b/d/well with conventional or highly deviated wells completed with 51/2-in. tubing and sand control measures. In the subsea production scheme, two wells are connected to each subsea manifold (Fig. 6a) and from the manifolds the fluids will to the FPSO through a innovative riser tower (Fig. 6b). Gas can be injected at the base of the risers for helping the oil flow to surface.

The insulation sleeves are made of rigid epoxy-based, high-thermal-performance, high mechanical-resistance foam containing micromarbles for better resistance to pressure.

The paraffinic Girassol crude oil will leave the wellheads at 65° C. and flow through 7 km of horizontal, bundled flowlines and then vertically to the top of the 1,300-m riser towers in 4° C. seawater (OGJ, May 8, 2000, p. 53). TotalFinaElf says without insulation, the average horizontal heat loss would be 18° C./km and the average vertical heat loss would be 10-12° C. Its studies show that below 40° C., the crude likely will deposit paraffin along the line, and below 20° C. hydrates are likely to form. To keep from plugging the lines, oil must reach the Girassol FPSO at no less than 40° C.

It expects the insulation to bring the average temperature loss to no more than 1° C./km and has designed the system to maintain the 27 km of crude oil gathering network at more than 40° C. The insulation design also ensures a minimum 20° C. for 16 hr to prevent hydrate formation in case of production shutdown.

TotalFinaElf expects to recover 725 million bbl of oil from the first stage of development.

Bonga

Shell Nigeria Exploration & Production Co. Ltd.'s (SNEPCO) Bonga field, Block OPL 212, development scheme includes high-rate horizontal and conventional wells produced through subsea well clusters connected to an FPSO with 2 million bbl storage capacity (Fig. 7).

Shell designed the facility to process 225,000 bo/d, 100,000 bw/d, and 170 MMcfd of associated gas, that will form part of the feed to the Bonny terminal. The field lies in 950-1,150 m water and is estimated to have 750 million bbl of recoverable oil.

SNEPCO, 55%, operates the license for Nigerian National Petroleum Corp. (NNPC) in partnership with Esso Exploration and Production Co. Nigeria Ltd., 20%, Nigeria Agip Exploration Ltd., 12.5%, and Elf Petroleum Nigeria Ltd., 12.5%.

Initial plans to produce the unconsolidated sand reservoirs, starting in 2003, call for 20 producing wells that will be frac packed in the conventional wells and openhole gravel packed with prepacked screens in the horizontal wells.

SNEPCO also plans to start water injection for pressure maintenance from the start of the project through 16 water injection wells with an estimated capacity to inject 300,000 bw/d.

The design also includes provisions for artificial lift to boost production in the future and to kick off wells. Injection of lift gas at the riser base rather than downhole gas lift will be used. SNEPCO says the riser-base gas lift system prevents slugging at low flow rates and allows quick depressurization of the riser in shutdown situations.

The Girassol FPSO is to arrive on location off Angola in July, with production start-up expected at yearend 2001 (Fig. 5).