Equipment/Software/Literature

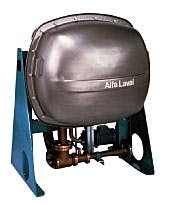

Titanium plate-type freshwater maker

Here's a thermal desalination system featuring the pressed plate falling film system to supply high-quality fresh water for domestic and process uses aboard vessels, drilling rigs, and offshore locations. This multieffect desalination system, which converts seawater into fresh water by vacuum distillation, is designed for automatic operation with continuous control of the freshwater quality.

The plate-type freshwater generator's plates are corrosion-resistant materials such as titanium and other noncoated seawater-resistant materials. Its simple, compact, low-weight design is simple to install and assemble on site and equally easy to dismantle and clean, the company says.

Source: Alfa Lava Inc., 9201 Wilmot Rd., Kenosha, WI 53141-1413.

New stick electrodes for pipeline welding

New stick electrodes designed for pipe welding promise quality and good bead appearance. For vertical down welding, there's the LH-D100 low hydrogen electrode and Shield-Arc HYP+. For vertical up welding, the company offers 16P and 18P electrodes for high-strength low temperature toughness.

The LH-D100 is designed for uses where low-hydrogen weld metal is demanded. This electrode has greater deposition rates than vertical up electrodes and downhill cellulosic electrodes of equal diameter, the firm says. It is suited for pipe grades API 5L Grade X80.

Its hot start feature focuses the heat into a pencil-point tip to help minimize starting porosity while helping to initiate the puddle. It can be used in any vertical down application where a low-hydrogen deposit is required. This new electrode rounds out this family of products, which also includes LH-D80 and LH-D90 electrodes as well.

Shield-Arc HYP+ provides a cleaner weld puddle and smoother arc action than former generations of this electrode. It has virtually eliminated the tendency for finger nailing and sticking. This electrode is designed to provide improved welding characteristics for downhill welding on fill and cap pass welding of API 5L-X52 through X65 high strength pipe. It also meets the requirements of the more restrictive AWS P1 class as well as E7010-G. Its design helps guarantee minimal spatter while providing the operator with a clean, visible weld puddle and smoother arc action.

The new 16P stick electrode is recommended for vertical up, open gap pipeline welding, up to and including X65 grade. It should be used where an AWS E7016 low hydrogen deposit exhibiting high strength and low temperature toughness is required. This stick electrode offers good low current stability with little risk of sticking. Easy slag removal and a fine rippled bead appearance round out the electrode's highlights.

The 18P is designed for vertical up fill and cap pass pipeline welding, up to and including X80 grade. It is recommended where an AWS 8018-G low hydrogen deposit exhibiting high strength and low temperature impact requirements are necessary. All sizes of this electrode have been designed for single and multiple pass fillet and butt welding and it can be used in all positions except vertical down. Much like the 16P, this electrode offers the square coating burnoff but goes a step further in even providing a moisture-resistant coating to prevent excessive moisture pickup.

Source: Lincoln Electric Co., 22801 St. Clair Ave., Cleveland, OH 44117-1199.

New metal-seated oil field ball valve

This new metal-seated ball valve is suited for chemical, oil, gas, and petrochemical operations.

The MS10000 Series valve is designed for trouble-free operation in critical applications including corrosive liquids, gases, and abrasive slurries.

It provides long-term shutoff integrity, extended packing life, extended bonnet with enhanced packing configuration, high-pressure capability, wear resistance, high flow rates, and sealed live-loaded seats to help assure tight shutoff at low differential pressure.

The valve is available with optional characterized inserts for control applications. The v-style metal inserts help provide precise throttling controls.

Inserts are designed to change flow characteristics of the valve and are offered in configurations to meet a variety of modulating applications.

The valve has a large actuator mounting pad that is drilled to ISO 5211 for easy actuator or gear fitting and alignment. In addition, accessories such as impact and chain wheel operators, locking devices, limit switches, and signal flags are available.

A range of materials of construction is available for the seats and body including Hastelloy, Alloy 20, F22, bronze, Monel, carbon steel, stainless steel, and other special materials. The size range includes 1/4 in. through 2 in. with flanged, socket weld, butt weld, and threaded ends.

Source: Marwin Ball Valves, 3170 Wasson Rd., Cincinnati, OH 45209.