Equipment/Software/Literature

Desiccant air dryer aids offshore operation

This firm's line of Pneudri desiccant air dryers was called into use recently by an operating oil company to supply a solution for the cement transfer facility on a North Sea offshore platform.

The existing compressed air system on board the platform consisted of two rotary compressors operating at a nominal 72.5 psig. The system had two prefilters and a single afterfilter. Located in the bulkhead of the rig, space was limited, and access to the compressors was also restricted. Daily use of bentonite required compressed air of high quality, reliably dried.

This firm's dryers proved suitable for this installation, the company says. The Pneudri package's modular design and shroud helped make maintenance easier to manage.

The company notes that its dryer is 30% smaller than traditional twin tower styles offering the same drying capacity.

Source: Domnick Hunter Inc., 5900-B Northwoods Parkway, Charlotte, NC 28269.

Multiport flow selector

This multiport flow selector is designed for production uses where equipment size, reliability, and control simplicity are factors.

It promises a cost effective method of selection and diversion of well fluids from an individual well to a single test outlet or test loop. Connecting up to eight flow lines, it allows the combined well fluids to flow through a group outlet while simultaneously isolating any single well for testing.

The selector provides a compact manifold with high operating efficiency, reducing weight and size of the production manifold. It has few moving parts, so maintenance is reduced.

The unit facilitates continuous well measurement, providing producers with accurate information, the company points out. It is especially suited for use with multiphase meters, both onshore and offshore.

The unit is available with an electric motor for ac or dc power supplies, is CSA certified for Class I, Division I hazardous applications, and is available with Cenelec certification to EEx d IIB T3, IP 55. It is also available with a microprocessor-based controller to monitor the rotor position and remotely control the unit with a PLC or local PC.

Source: Bettis Corp., Box 508, Waller, TX 77484.

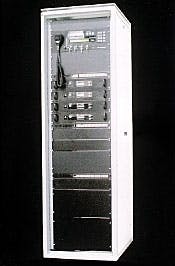

Offshore public address, general alarm system

A new microprocessor-based system is designed for public address and general alarm for offshore operations.

The Elemec Plus system is designed to meet routine and emergency communications and safety needs of offshore production operations.

The system combines intelligible voice messages with alarm capabilities for facility communication. Features include remote system monitoring and automatic speaker level adjustment. Its redundant architecture helps assure continuous operation even if a component or group of components fails.

Routine speech announcements can be directed to any or all areas of the installation. Emergency announcements may be accompanied by strobe light illumination in noisy areas to attract the attention of all personnel. Announcements may be made from system control panels or from standard telephones through a dial-in feature.

An alarm can be activated at any of the control panels and broadcast to preselected areas or the entire facility. The alarm sounds and strobe lights flash until the event is canceled.

The system can be integrated to a PC control monitor to allow a system operator to monitor and manage real-time system operations from an on-site or remote location. System information, such as page detection, equipment failure, and alarm activation, can be recorded and downloaded to a printer or file for future analysis and use.

Source: GAI-Tronics Corp., Box 1060, Reading, PA 19607-1060.