Spent-caustic treating technology converts waste into saleable byproduct

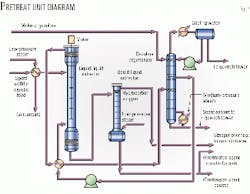

The first commercial Pretreat unit (Fig. 1), started in July 1999, was built as part of the second ethylene unit project of Companhia Petroquimica do Sul (Copesul), in Triunfo, Brazil.

This Pretreat unit was installed upstream of a Stone & Webster Inc. (S&W)-BP spent-caustic wet air oxidation (WAO) unit and S&W ozonation unit.

Copesul sold the treated spent caustic from the Pretreat unit, which met the stringent specifications of pulp and paper manufacturers, to a local pulp and paper mill.

The WAO and ozonation units essentially function on standby.

The technology was developed by S&W1 2 as a result of extensive pilot plant tests performed on representative spent-caustic solutions from three ethylene plants using different feedstocks: Petromont Inc. in Varennes, Que.; Chevron Chemical Co. in Port Arthur, Tex. (now Chevron-Phillips Corp.); and Copesul's No. 1 plant in Triunfo, Brazil.

Purpose

The resulting treated spent caustic from Pretreat is acceptable for use within the pulp and paper industry. This spent-caustic product sale permits zero discharge of liquid caustic effluent from the olefin complex, thus, preventing the potential discharge of more than 6,000 tons/year of sodium salts (mainly NA2CO3 and NA2SO4) to the environment if the spent caustic were oxidized and neutralized.

The Pretreat process conditions spent caustic to remove polymer precursors that cause fouling problems in downstream processing steps. The process extracts hydrocarbon contaminants from spent caustic with a hydrogenated aromatic-rich solvent, typically available at the plant site.

The process essentially removes all dissolved hydrocarbon, polymers, and polymer precursors.

If the spent caustic is not sold, it must be treated to reduce its high COD (chemical oxygen demand) due mainly to its NA2S content. The two most common methods of spent-caustic treatment are WAO and incineration.

Pretreatment of the spent caustic enhances the performance of both conventional and catalytic WAO reactors significantly and prevents fouling of the WAO unit equipment.

Similarly, pretreated spent caustic will ensure longer run lengths for incineration units because it eliminates fouling of the feed heater and burner tips.

Spent-caustic composition

Spent caustic from caustic towers in ethylene plants contains significant contaminants, which include dissolved hydrocarbon, polymers, and active polymer precursors in addition to the well-defined levels of sodium salts and free caustic. These lesser-known contaminants can foul spent-caustic-processing equipment and grossly inhibit the oxidation level of sodium sulfide to sodium sulfate.

The polymerization rate of polymer precursors increases with increasing temperature and pressure. Polymerization of the carbonyls by aldol condensation is catalyzed by free sodium hydroxide in solution, while additional polymerization of dienes is catalyzed by oxygen, oxidizing agents, and heavy metal ions.

The organic constituent of the spent caustic is present in two forms: a dissolved phase and a free separate phase.

The organic components dissolved in the aqueous phase have different concentrations defined by their solubility limits.

On the other hand, the unsaturated hydrocarbons and light aromatic components have significantly higher solubility limits than the saturated and heavy organics. The organics present in the spent caustic beyond their solubility limit in the aqueous phase exist as a separate phase in the form of oily droplets and solid polymer particles that are visible within the spent-caustic solution.

Conventional conditioning

Conventional methods available partially to remove contaminants from spent caustic include deoiling and degassing.

Deoiling with gasoline involves contacting the spent caustic with large volumes of recirculated gasoline in a deoiling drum. Only a small quantity of fresh gasoline is added to the system, and a small quantity of spent gasoline is purged from the system with its dissolved oils and polymeric solids.

While a major part of the polymeric material is removed, the spent caustic becomes saturated with the components from the gasoline, and only minor amounts of the dissolved organics are removed from the spent caustic.

Although deoiling is effective in removing the free hydrocarbon and the solid polymeric material from the spent caustic, the polymer precursors remain in solution. Deoiling does not remove any substantial amount of the dissolved hydrocarbon in the spent caustic because of the low net effective extract-to-raffinate phase flow rates ratio that is used in the deoiling process.

Degassing the high-pressure spent caustic is achieved by lowering its pressure to near atmospheric in a degassing drum. Degassing removes most of the light, low solubility hydrocarbons. The active (and reactive) unsaturated and heavy organics remain in solution; these are the polymer precursors.

Pretreat process

Upstream of the Pretreat unit, the spent caustic from the caustic tower is deoiled to remove the polymeric material formed in the spent caustic. It is then degassed by flashing part of the dissolved hydrocarbon gases. The spent caustic is then stored in a spent-caustic tank where oil and polymers float and are skimmed off from the spent caustic.

The Pretreat unit as shown in Fig. 2 consists of:

- Liquid-liquid (L-L) extractor.

- Hydrocarbon stripper.

- Gasoline regenerator.

The deoiled spent caustic and the hydrogenated aromatic-rich extracting solvent are counter currently contacted in a low shear liquid-liquid extraction column (Karr extractor), which minimizes emulsion formation.

The extractor is sized to give 5-10 theoretical stages with hydrogenated gasoline at 75-85° C. It transfers the polymerizable carbonyls and dienes from the aqueous caustic phase to the aromatic gasoline phase. In the extractor, more than 95% of the polymeric materials and polymer forming carbonyls and dienes are removed.

The spent caustic, the bottoms product from the L-L extractor, while in contact with the gasoline, becomes saturated with the light aromatic components of the gasoline. These are stripped in the hydrocarbon stripper; overhead stripper gas is routed to the quench tower.

Steam stripping of the extracted spent caustic removes more than 99% of the benzene and lighter materials and more than 95% of the toluene. Heavy organic materials are not removed by stripping.

A filter with a mesh basket removes any polymers that are formed during the stripping process from the stripped spent-caustic effluent stream.

Mercaptides present in the spent caustic, mostly CH3SNa and some C2H5SNa, are hydrolyzed in the stripper into CH3SH and C2H5SH, which are readily stripped out into the overhead vapor. That is, RSNa+H2O to RSH + NaOH.

A dedicated gasoline regenerator purifies the hydrocarbon extract and recycles the regenerated gasoline back to the L-L extractor. The gasoline regenerator also purifies the makeup gasoline from its light and heavy components.

Advantages of Pretreat

Pretreat has two major advantages:

- It converts the waste spent caustic to a saleable product.

- If the spent caustic is not sold, it improves oxidation of the spent caustic.

Downstream of the Pretreat unit, the WAO reactors oxidize the spent caustic to reduce its COD to the desired level before discharge. The efficiency of the oxidation step is a function of the amount of dissolved hydrocarbon present in the spent caustic.

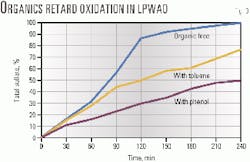

Pilot plant test results3 plotted in Fig. 3 show the impact of toluene and phenol in the spent caustic on the WAO reactor efficiency of the conversion of NA2S to NA2SO4. The results clearly indicate that the presence of hydrocarbons in the spent caustic significantly retards the oxidation reaction.

Thus, Pretreat enhances the oxidation process, resulting in more efficient oxidation (better conversion of NA2S to NA2SO4) and potential elimination of a secondary oxidation step.

The spent caustic generated in ethylene plants can be used in pulp and paper mills as makeup alkali in the Kraft recovery process. The hazardous nature of aromatic hydrocarbons, polymers, and polymer precursors, however, tends to inhibit this practice.

By reducing the quantity of hydrocarbons, polymers, and polymer precursors to less than 10 ppm in the spent caustic, the Pretreat process makes spent caustic attractive for use in pulp and paper mills.

Pretreat converts a hazardous waste in the ethylene plants to a valuable byproduct.

Other similar uses of pretreated spent caustic are found in noble metal catalyst manufacture, metal treatment processes, and leather tanning.

The large number of pulp and paper units throughout the world (5,700 total) offer under-utilized opportunities for economic and environmentally responsible disposal of spent caustic from the ethylene unit.

Commercial results

Copesul considered the disposal of spent caustic from both its No. 1 and No. 2 ethylene plants as a critical issue. It thus supported both pre- and post-treatment in conjunction with the oxidation stage.

The four sequential treatment steps consisted of:

- Pretreat unit for spent-caustic conditioning, consisting of a Karr L-L extractor, a hydrocarbon stripper, and a gasoline regenerator.

- Bulk oxidation using low-pressure WAO (LPWAO; S&W/BP technology).

- Final oxidation using ozonation (S&W technology), consisting of an ozone generator package and an ozone contactor.

- Neutralization package unit.

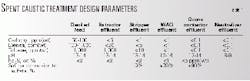

Table 1 summarizes the essential design specifications of the spent-caustic system by their respective process stages. Table 2 shows the salt content in the spent caustic before treatment.

S&W designed the new system to treat the streams from both ethylene unit caustic towers at a rate of 4 tons/hr.

With the new Pretreat unit, all the design specifications were satisfied or exceeded.

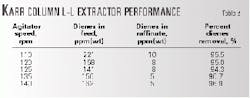

Table 3 lists the performance of the extractor during Copesul's performance test run. The extractor design parameters were:

- Complete removal of the carbonyls and greater than 95% removal of dienes from the spent-caustic feed.

- Less than 20 ppm(wt) of dienes in the raffinate.

The raffinate from the Karr column L-L extractor is steam stripped in the hydrocarbon stripper.

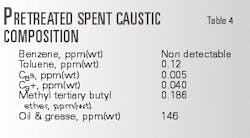

The unit was designed to remove toluene to less than 1 ppm(wt) as a measure for its efficiency in removing the hydrocarbon content of the spent caustic. Table 4 lists the hydrocarbon content of the pretreated spent caustic.

The stripper has operated at 135° C. without fouling for the past 18 months.

This has resulted in complete removal of benzene from the spent caustic and a decrease of toluene to 0.12 ppm(wt).

The oil and grease content of 146 ppm(wt) was largely a result of the polymer formation of the dienes left in the raffinate feed.

The pretreated spent caustic is filtered through 5 µm media upstream of the WAO reactor for removal of suspended polymers down to a hydrocarbon content of 10 ppm (wt).

The WAO and ozonation units operate only on a stand by basis; no fouling problems have been reported.

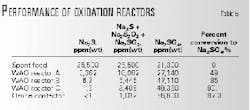

Table 5 shows the average composition of sulfur compounds in the WAO reactors and the ozone contactor. The oxidation contactors exceeded its design values in two ways:

- The NA2S content in the oxidized product is less than 1 ppm(wt). The design guaranteed 5 ppm(wt).

- There was a 97% conversion of NA2S to NA2SO4 in the oxidized product. The design guaranteed 90%.

References

- Stone & Webster US patent No. 5885422, "Spent Caustic Pretreatment Process," Mar. 23, 1999.

- Stone & Webster US patent No. 6210583, "Spent Caustic Pretreatment and Enhanced Oxidation Process," Apr. 3, 2001.

- Small, "Performance of Low Pressure Wet Air Oxidation Unit," AIChE Spring National Meeting, Houston, Apr. 17-21, 1994.

The authors

Sabah Kurukchi is senior technology specialist at Stone & Webster Inc. He has extensive process engineering experience in evaluating and designing solutions for separation processes. He also consults in the design and retrofit of acid gas removal systems, spent-caustic treating, contaminant removal systems, fractionation, and fractionation towers. Kur ukchi holds a BS in chemical engineering from London University, UK, and a PhD in distillation from Loughborough University, UK.

Joseph Gondolfe is an olefins technology manager and worldwide program director for Stone & Webster Inc. He has 20 years of design engineering experience in the petrochemical business. He specializes in process development and distillation in extractive distillation, azeotropic distillation, and solvent recovery. Gondolfe holds a BSc in chemical engineering from the University of Massachusetts, Lowell. He is also a board director of the Industrial Advisory Council for the University of Massachusetts.

Roger Leite Kirst is a project unit executive at Copesul, Triunfo. He is in charge of new projects and was the project manager for the Copesul expansion project, which included the spent-caustic treating unit. Kirst holds a BS in mechanical engineering from Funda ao Universidade de Rio Grande, Rio Grande, RS, Brazil.

Luiza Milbroth Jorge is a process engineer at Copesul, Triunfo. She is a technical supervisor in the caustic and spent-caustic treatment area of the olefins plant. Previously, she worked on the aromatics unit revamp and in the research and development department. Milbroth holds a BS in chemical engineering from Univer sidade Federal do Rio Grande do Sul, Porto Alegre, RS, Brazil.