Float-over method installs large topsides off Philippines

null

null

null

null

A float-over method was used to install the topsides on the Malampaya field's concrete gravity substructure (CGS) off the Philippines on Mar. 17, 2001. Shell Philippines Exploration BV is operator of the gas and condensate field, 50 km northwest of Palawan Island.

Shell expects to start supplying gas from the field to power plants in the Philippines by Oct. 1, 2001, after commissioning of an onshore gas plant.

Kellogg Brown & Root (KBR), a business unit of Halliburton Co., oversaw the engineering, procurement, fabrication, and installation of the facility.

Topsides

KBR says that at an installation weight of 11,500 tonnes, the Malampaya topsides is the largest integrated deck ever installed in the Asia-Pacific region and is currently the largest offshore topsides in the world installed with a float-over method. This method allows a complete integrated deck to be installed as one unit, thereby maximizing onshore fabrication and testing.

The 40 by 92-m topsides has three decks: weather, production, and cellar decks. It contains equipment for separating produced water and condensate from the wet gas stream flowing from subsea wellheads. The facility is in 43-m water (OGJ, July 17, 2000, pp. 58-59) and the subsea wells are in 850-m water (OGJ, Dec. 4, 2000, pp. 69-70).

Topside facility construction commenced on May 27, 1999 in Singapore at the SembCorp Engineering International Pte. Ltd. (Sembawang Marine & Offshore Engineering) yard. KBR installed the concrete base for the platform in the summer of 2000.

Installation

Heerema Marine Contractors Nederland BV's newly constructed H-541 barge transported the topsides 1,134 nautical miles from Singapore to the field location. Three tugs towed the 165 by 42-m barge.

KBR says sea states during the tow were generally calm with swells of up to 2 m and that the tugs, with a combined power of 39,000 bhp, generating a bollard pull of up to 300 tonnes and maintained an average 5-knot speed during the tow.

The tow started at 7 a.m. on Mar. 1, 2001, and arrived at the destination on March 10.

At the location, the Rockwater 2, a Halliburton owned dynamically positioned vessel, a maneuvering tug, and another ocean going tug assisted in the installation.

KBR says on Mar. 14 a second maneuvering tug joined the installation spread and all eight vessels were ready for the installation, but the sea state did not allow commencement of the installation until Mar. 16.

After the sea had calmed to 0.5 m swells and with a good weather forecast for the next 72 hr, KBR commenced the installation at 6 a.m. on Mar. 16.

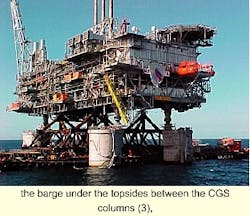

The four photos (opposite page) show the installation sequence.

KBR describes the procedure as follows:

- One tow and one docking tug commenced maneuvering the H-541 barge to the CGS location. Two prelaid anchors and four docking lines attached to the CGS shafts were connected to winches on the H-541 barge and the H-541 was then maneuvered between the legs of the CGS.

- At 3:10 a.m. on Mar. 17, the H-541 barge was connected to the first of the 4-in. diameter steel-wire mating lines and by 7:45 a.m. all mating lines had been connected and environmental conditions were confirmed as within limits for the installation.

- Ballasting operations commenced with 36 pumps for transferring seawater at more than 21,000 tonnes/hr into the H-541.

- At 3:20 p.m., first contact was made between the CGS leg mating units and the deck leg supports of the topsides facility. Rubber columns in the deck legs and on the transportation frame allowed a progressive transfer of weight to the CGS.

- After 57 min, the topsides weight had been fully transferred to the CGS and 9 hr later the H-541 barge was clear of the platform.

- Sand jacks on each of the four CGS leg mating units were then simultaneously released allowing the topsides to be lowered in a controlled manner into its final position. The contact points were then welded together to form the one permanent structure of the Malampaya platform.

Offshore commissioning

KBR says it will use the Rockwater 2 as its construction support vessel during the offshore commissioning phase that has starting.

Its target is to complete platform commissioning so that the platform can begin, by Aug. 1, 2001, processing gas for the 504-km pipeline to shore. It says this target date will allow the onshore gas plant at Batangas on Luzon Island to be commissioned on schedule.