Equipment/Software/Literature

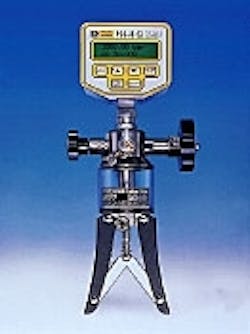

New pressure calibrator

Designed for use in hazardous environments, the PC6-IS pressure calibrator is suited for oil field use offshore and onshore.

The unit promises accurately to test and calibrate pressure transducers, pressure transmitters, pressure switches, pressure relief valves, and analog instrumentation (pressure gauges). The PC6-IS simultaneously shows pressure vs. voltage, current, date and time, percentage of pressure, pressure switch status, temperature, and maximum or minimum pressure values. Data can be stored and logged with time and date stamping for future reference.

The instrument has an operating temperature of 0° to 40° C., a calibration temperature of 20° C. ±2° C., and a calibration temperature range of 10-40° C. Its storage temperature is -20° to +70° C., and temperature effects are 0.001% of reading/°C. between 10°-40° C. The LCD display permits 16 characters by two-line alphanumeric, and its small and portable structure (92 by 110 by 60 mm dimensions, and 1.2 kg weight) offers a pressure measurement range of -1 to 1,000 bar/15,000 psi.

Pressure media includes water, oil, and noncorrosives gases. The rechargeable battery pack (to be charged in nonhazardous areas only) is a 7 v NIMH/mains operation, and the electrical connections permit ground, voltage/current input, pressure switch input, battery charger, RS232 and EPM. SI Cal software is optional and will allow users to control the pressure calibrator remotely through a virtual instrument panel on a computer screen. The calibration data can then be viewed, logged, and printed in graphical format or on a calibration certificate (to be used in nonhazardous areas only).

Source: TTI Inc., Box 1073, Williston, VT 05495-1073.

System helps quantify pipe friction losses

A new system is designed to help quantify friction losses, identify shock losses, locate damage regions, find high pressure or vacuum regions, and allow for precise planning of routing extensions to existing small diameter pipeline systems.

The 35 mm diameter by 70 mm long PSI-Pill travels pipelines of extreme lengths and configurations. While en route, the pill samples pressure at user-defined rates up to 10/sec. The 8 hr lithium onboard battery and data logger collect up to 16,000 pressure readings in ASCII format, which are easily and quickly downloaded to the user's PC. The resulting pressure trace assists diagnosis of friction losses, freefall regions, impact zones, water hammer, and flow velocities.

Pump designers can also use the device to verify the performance of their units over the long haul. Existing models allow users to examine pipelines as small as 3 in. diameter. Future pill designs include thermocouples, accelerometers, three-directional gyros, and pipe wear or pipe diameter sensors, the company notes.

Source: Paste Systems Inc., 161 Larch St., Sudbury, Ont. P3E1C4.

Serial-to-Ethernet terminal server

The new Director TS terminal server promises the high level of configurability needed to effectively connect a wide range of legacy equipment supporting serial communications to local area networks or the internet, and the ruggedness to withstand oil field environments.

It is a four-port terminal server device that allows a single IP network connection to maintain four serial links simultaneously. This new product helps simplify the job of communicating with digitally monitored devices throughout plants, and with remote field devices that currently only talk serially to a dedicated PC or control panel.

Oil companies can use the product to gather, transmit, and distribute data from remote field devices across their entire enterprise networks, the firm points out.

By using packet optimizing, the Director TS helps reduce bandwidth costs over metered circuits, the firm says. Its architecture helps make it easy to implement across almost any network and allows communications with a virtually unlimited number of devices. Its construction and enclosure, onboard power supply, and operating temperature range of -40° to +70° C. help suit it for oil field applications.

The device supports three RS-232 and one RS-232/485 serial port, and offers 10 MB Ethernet interface through an RJ45 port. It offers a number of dc input options, including 9-18 v dc, 18-36 v dc, and 36-72 v dc, plus an ac power option.

Among its features it:

- Incorporates industry-standard TCP/IP connectivity.

- Provides easy PLC/RTU programmability with IEC-1131-3 standard software suite.

- Can run remote diagnostics without affecting normal operation.

- Interfaces with multiple physical topologies-radio, microwave, ISDN, PSTN, LAN, leased line, or Ethernet

- Protects capital investment-incorporates products with dissimilar protocols onto one common platform.

- Utilizes standard Windows-based configuration.

Source: Arcom Control Systems, 13510 S. Oak St., Kansas City, MO 64145.