Equipment/Software/Literature

Capacitive accelerometers

Durable packaging for harsh industrial use characterizes the Series 650 capacitive accelerometers.

These devices utilize the same precision capacitive sensing elements, originally designed for use in test and evaluation sensors, for measuring low-level, low frequency vibration and static acceleration.

Suited for vibration monitoring of large machinery, slow rotating rolls, and heavy equipment, as well as for structural integrity and foundation testing, these units feature strong output signals, low noise operation, and shock protection to 3,000 g.

Other features include stainless steel housings, all-welded hermetically sealed construction, sensitivities up to 1 v/g, and rugged four-pin military connectors or integral cables. A variety of powering options accommodates portable operation from a battery source.

Source: IMI Sensors Div., PCB Piezotronics, 3425 Walden Ave., Depew, NY 14043-2495.

Mechanically sealed asphalt pumps

This firm is now offering mechanically sealed versions of its general purpose and heavy duty asphalt pumps. Both series of pumps are now available with cartridge-type lip seals, or single or double mechanical seals in addition to packing.

Used by refiners, asphalt pumps are traditionally provided with braided shaft packing instead of mechanical seals, the company points out. But packed pumps must have some leakage to lubricate the packing, which releases asphalt fumes and causes increased housekeeping, environmental cleanup problems, and loss of valuable product, the firm notes. It says mechanically sealed pumps eliminate the leakage and the problems associated with leakage.

The company offers seal options for all types of asphalt, including polymer-modified and filled asphalts. With pressures up to 200 psi (0-14 bar), the firm offers asphalt pump capacities of 1.5-1,500 gpm (0-345 cu m/hr).

Source: Viking Pump Inc., Box 8, Cedar Falls, IA 50613-0008.

New interlocking sheet piling panels

New, 1 and 2 ft wide thermoplastic sheet piling panels interlock during installation to form barrier walls for a range of geotechnical, environmental remediation, and containment uses.

Extruded from heavy-duty, exterior grade engineered thermoplastic. These Perma-LOC environmental barrier wall panels promise durability and impact strength and are impervious to corrosion, chemical attack, and UV degradation. Uses include cut-off walls, embankments, settling ponds, levee reinforcement, stabilization and retaining walls, as well as use in conjunction with in situ processes, the manufacturer says.

Unlike traditional Z-shaped versions, Perma-LOC panels are designed to be driven one at a time.

Because the 2 ft Perma-LOC 9000 and 9900 panels are wider than most other thermoplastic sheet piling panels, the firm says, installation time is shorter, and interlocks are reduced by 50% to minimize areas of concern. The 1 ft wide 2500 and 4500 panels are suited for hard-to-access areas and can be driven with lightweight, hand-held equipment. All panels have the strength and rigidity required for impact installation, the firm notes. Standard equipment such as jack and vibratory hammers or backhoes can be used for installation. Cranes, pile drivers, and drop hammers can be used for larger jobs or faster installation.

Source: Crane Products Ltd., Box 1898, Columbus, OH 43216-1898.

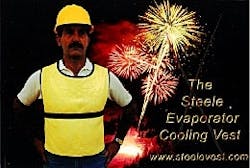

High visibility cooling vest

The high visibility Evaporator cooling vest offers one solution to staying cool when it's hot.

The vest supplements the body's natural sweating process by providing water for additional evaporation to help keep the wearer cooler and hydrated. To use, simply dip in water, wipe the inner surface dry, and wear. The proprietary three layered vest material is disposable and will provide about 1 month of affordable use for a cost of about $1/day, the company says.

Source: Steele Div., Frisby Technologies Co., Box 7304, Kingston, WA 98346.