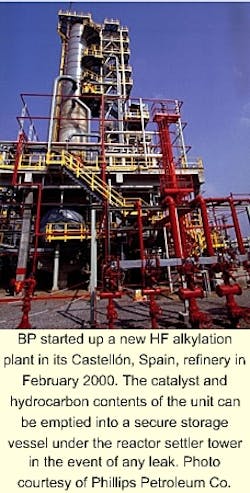

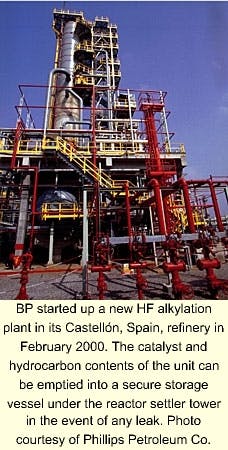

Spanish refinery takes precautions in alky-unit design

In February 2000, BP 's Castellón, Spain, refinery commissioned a new hydrofluoric acid (HF) alkylation unit, employing Phillips Petroleum Co.'s HF alkylation process. The 3,500-b/sd alkylation unit was part of a $36.8-million project to make clean-burning, high octane gasoline.

Both Phillips and BP took care to design a unit that safely manages the strong acid catalyst.

The alkylation unit was installed as a lumpsum, turnkey project whose cost included licensing fees, construction, change-order, and start-up costs.

Refinery feed, products

The refinery processes 100,000 b/sd of crude. Low-sulfur Nigerian crude makes up 35-40% of the feed. Russian crude provides about 20% of the feed, and Mexico, Libya, and other sources provide the remaining crude.

The BP Castellón refinery produces 5 million tonnes/year of petroleum products, mostly for domestic consumption. Some 95% of the refinery's output is sold in Spain.

About 44% of the refinery's 1999 production was diesel fuel; the remaining 1999 production consisted of motor gasoline (24%), bunker fuel oils (14%), kerosine (8%), LPG (5%), and asphalts (5%).

The alkylate product is a high octane gasoline-blending component that has a low sulfur, aromatics, and benzene content and a low Reid vapor pressure (Rvp).

Specifications of the resulting gasoline at the refinery are better than EU regulations currently require.

While the HF alkylation unit is designed to produce an alkylate with a research octane number (RON) of 95 and a motor octane number (MON) of 93, it sometimes produces gasoline with a 95.5 RON and a 93.5 MON, said Diego Fernández de la Mata, a process engineer for the refinery.

BP built the alkylation unit to use the isobutane in the refinery, said Fern&ández. "We have a high-isobutane feed stream, and we wanted to convert it to gain the highest commercial value-the highest octane," he said.

The new alkylation unit eliminates BP's need to import alkylate to produce unleaded gasoline, improving refinery profits while still allowing the refinery to maintain its domestic market position.

Unit construction

Javier Prats, BP project engineer for the alkylation unit, began the project by working part-time in Madrid 11/2 years to manage preconstruction planning and detailed design engineering. He returned to Castellón full-time in mid-1998 to oversee the civil and construction work.

BP used the May 1998 turnaround to install about 70 infrastructure tie-ins for the unit, he said.

Most of the major fabrication and engineering firms were from Spain. They included Tecnicas Reunidas (engineering contractor), Talleres Mac SA (fabricator of reactor and other vessels), Aguilar y Salas (acid-rerun columns fabricator), Schwartz Hautmont (main fractionator fabricator), Cotinsa (mechanical contractor), Denion (instrumentation contractor), Mesal (electrical contractor), Agroman and ACS (civil contractor), and Pefipresa (water-mitigation systems).

Drãgerwerk AG, Lübeck, Germany, provided the HF and hydrocarbon detectors; Honeywell, Morristown, NJ, provided the DCS instrumentation and controls; and Applied Automation (now Siemens Applied Automation), Atlanta, provided online chromatographs.

All vessels and equipment arrived on site via land except for a large flare drum, which arrived by ship.

Safety evaluation

The refinery is less than 10 km south of Benicássim, a Spanish Mediterranean coastal resort, and is surrounded by homes and orange groves. It thus carefully considered its impact on the environment when selecting the alkylation process.

Three other Spanish refineries use HF alkylation. These refineries were accessible sources of training and advice on HF catalyst for BP. In studying the HF alkylation process, BP engineers examined units at these refineries as well as BP units in England and the US.

Since the HF is easily regenerated on site, said Fernández, BP minimized the amount of acid trucked in and out of the refinery, reducing the chance of spills. The new unit requires 3-3.5 truckloads of replacement HF yearly.

The unit uses a dedicated water-cooling tower to eliminate any possible water contamination from the unit's coolingwater system. The tower cools water only from the alkylation unit and the hydrogen plant.

The refinery's restrictions on water pollution and effluent controls are more stringent than national and EU standards because of its proximity to the Mediterranean Sea and the importance of groundwater to regional agriculture.

To ensure complete control over the alkylation unit, BP duplicated the control systems in the local alkylation unit in a blast-proof main control room six blocks away. The control of every part of the unit-from the lights to the water mitigation system to the acid dump-is duplicated.

The accompanying box lists key safety and operational measures that Prats recommends for refiners planning an HF alkylation unit.

Rapid acid dump

Part of the security of the personnel depends on the rapid acid-dump system, a safety feature included with the Phillips alkylation process. The system ensures a quick deinventory of the catalyst should an unlikely leak occur.

The rapid acid-dump system is designed to empty the HF catalyst from the alkylation reactor into a secure storage vessel within 8 min. The storage vessel is sized to contain both the acid catalyst and the reactor hydrocarbons, olefins, and isobutane.

The refinery activated the dump system two times, once as a test before the alkylation unit started and again during an early alkylate production run. In both instances, the dump was quicker than the predicted design.

BP and Phillips planned and conducted the prestart-up test with water to prevent potential contamination and cleanup problems. While the water-test dump took about 10 min, the "operating acid and hydrocarbon mixture" was safely contained in the secure holding tank in about 2 min.

The second rapid acid dump occurred when an electrical malfunction in the control computer UPS (uninterruptible power supply) initiated a dump sequence. As trained, the operators immediately shut down the unit and analyzed the system to find the problem.

Water-mitigation system

To mitigate any potential acid escape, BP revised other standard water-curtain designs.

Instead of installing water piping and high-volume spray nozzles around the unit perimeter, refinery engineers placed full water-curtain systems around each individual key vessel in the alkylation unit-the reactor-settler, the acid-return column, and the acid coolers, for example.

"The idea is to knock down any potential acid vapors as close to the source as possible," Prats explained. "We want to keep any acid drift to an absolute minimum."

Even the truck pad where a tanker will park to deliver fresh catalyst to the unit has a pipe-and-nozzle water system.

The system also includes five remote-control fire monitors (water cannons) placed so that operators in the unit or plant control rooms can aim a high-pressure water stream at any leak in the unit.

A large reservoir captures mitigation water, rain, or runoff from the unit until the water can be tested, neutralized, and pumped through the refinery's water-treatment systems.

Recommended safety, operation measures

- Take special care with all flange faces and any gasketed connections. Carefully examine all the flanges on vessels and piping exposed to HF. Be ready to remachine some flange faces to ensure perfect surface finish.

- Conduct complete unit leak tests with water and with nitrogen. Correct even the smallest leaks before start-up. Alkylation units are unlike other refinery units that can be fine-tuned after start-up. Any potential problems must be corrected before starting the alkylation unit.

- Paint every flange and connection in the alkylation unit with special acid-detection coatings that change color when exposed to HF. That permits operators to tell at a glance if there is a leak at any fitting.

- Install HF and hydrocarbon sensors around the perimeter and at key points within the unit to optimize leak detection. There are 15 detectors in and around BP's Castellón HF unit.

- Give every refinery worker a basic course in HF operation and safety. Provide additional detailed training for all alkylation-unit personnel. The more people know about the process, the less they will fear it and the safer they will be.

- Visit as many operating alkylation units as possible. Find out how other units handle unit start-up and operation. Learn from them. Improve what you can, and share your improvements with other refiners.

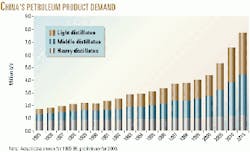

CORRECTION

The value indicated by the bar for the year 2015 was misrepresented in the figure that appeared in OGJ's Asia's Downstream Future special report (OGJ, Feb. 19, 2001, p. 68). The corrected figure is shown above.