Complex well geometries boost Orinoco heavy oil producing rates

Petrozuata CA is resorting to complex multilateral well completions for recovering heavy oil from its Venezuela contract area.

It required the more-complex wells after finding a much more compartmentalized reservoir than initially expected.

Original plans had called for developing its large 57,000-acre contract area (Fig. 1) with single horizontal laterals.

Petrozuata, a strategic association between Conoco Inc. (50.1%) and Petroleos de Venezuela (PDVSA; 49.9%), is an integrated company comprised of upstream, downstream, pipeline, and marine operations.

Orinoco heavy oil

Petrozuata's heavy oil (8-10° API) project is in the Orinoco belt, a huge deposit of heavy and extra-heavy crude that covers an area of 700 by 50-100 km in the states of Monagas, Anzóategui, and Guárico.

Estimates indicate that the belt contains 1.2 trillion bbl of oil in place, with ultimate recovery possibly reaching 240-270 billion bbl. PDVSA splits the regions into four areas: Cerro Negro, Hamaca, Zuata, and Machete (Fig. 1).

Drilling in the region started in 1935, but only 58 wells were drilled in the next 30 years, according to PDVSA. Between 1978 and 1983, PDVSA commenced a more thorough exploration of the area that quantified and characterized the resources.

The producing Oficina formation lies at a depth of about 2,000-4,000 ft. Cerro Negro has the thickest best-developed sands, with reservoir thickness and quality generally decreasing to the west and south.

PDVSA to date has formed four strategic associations with companies outside Venezuela to exploit the heavy oil area. First was the venture with Conoco to form Petrozuata, approved by the Venezuelan Congress in 1993. The others are Cerro Negro (41.67% ExxonMobil Corp., 41.65 % PDVSA, and 1.66% Veba Oel AG), Sincor (47% TotalFina, 38% PDVSA, and 15% Statoil), Petrolera Ameriven in Hamaca (40% Phillips Petroleum Co., 30% PDVSA, and 30% Texaco Inc.).

Petrozuata's and Sincor's Zuata projects will transport their production in the same 125 mile, 36-in. pipeline and obtain diluent from a parallel 20-in. pipeline. These lines link the production area (Fig. 2) with upgrading and export facilities at Jose, on Venezuela's northern coast, near Puerto La Cruz.

Petrozuata started producing in August 1998 and averaged 40,000 b/d of 9° API oil from 42 wells in December 1998. Production has increased to about 92,000 bo/d from 104 wells in mid-January 2000. About 22 million bbl were produced through 1999, and another 35 million bbl of heavy crude are expected to be produced in 2000.

In the other strategic associations, Cerro Negro production began in December 1999 at an initial 60,000 b/d of diluted oil. Sincor expects to be in production in November 2000 and Ameriven might follow in early 2001.

Petrozuata's 9° API oil is currently blended with a 30° API Mesa crude to obtain a 16° API blend, but after completing its upgrader, it will start to use a 47° API naptha for a diluent instead of the Mesa crude.

All four joint ventures are at various stages of completing upgraders at Jose. The upgraders will use delayed-coking to produce syncrude and byproducts of LPG, sulfur, petroleum coke, and heavy gas oil.

Petrozuata expects its upgrader to be ready by the third quarter 2000. Cerro Negro's upgrader will follow, starting in early 2001, Sincor's in early 2002, and Ameriven's later in 2002.

Petrozuata estimates that 1.5 billion bbl of 8-10° API gravity oil will be recovered from its area over the 35-year contract term. During this time, it will be producing at a 120,000-bo/d plateau.

Petrozuata's investment in the project is about $2.8 billion. This includes about $1.4 billion for the upgrader and $700 million for the production facilities, drilling, and pipelines. The rest is attributed to financing costs.

Well completions

Petrozuata commenced drilling producing wells in August 1997 and currently has in the field two drilling rigs, one stratigraphic well rig, and one well-service rig. It plans to add two more drilling rigs by the end of February.

The total number of wells is yet to be determined. Originally Petrozuata planned to drill about 500 wells but this may change as it gains additional production history.

Petrozuata batch-drills the wells from pads, setting 133/8-in. conductor and 95/8-in. intermediate casing in wells before drilling into the producing zone. It is one of very few companies to drill 5,000 ft plus horizontal laterals in unconsolidated formations and also claims to be the first company to utilize 5,000-ft multilateral wells.

To drill the wells, Petrozuata brought in the Canadian drilling contractor Precision Drilling International, Calgary, because of its experience with heavy oil in Canada and the operation of self-moving rigs to drill multiple wells from a single well pad.

One current rig in the field for drilling producing wells is a triple self-moving rig, while the other is a super-singles automated rig that handles 45-ft drill pipe joints. A self-moving rig can move from wellhead to wellhead without needing to lower its mast or lay down drill pipe. The super-singles rig has the advantage of being more mobile between well pads.

By mid-January 2000, Petrozuata had drilled 151 surface holes, drilled and cased 122 production holes, set 118 wellheads, completed 110 wells, and drilled and logged 83 stratigraphic wells. Ninety-two of the wells have single horizontal laterals and 27 have the following multilateral configurations (Fig. 3):

- Four fishbone or herringbone wells.

- Eight three dimensional gull wings.

- Ten stacked multilaterals.

- One stacked fishbone.

- Three stacked gull wings.

- One triple lateral.

Petrozuata indicates total footage drilled through mid-January was about 1.2 million ft, with an average 10.58 days/well for drilling the multilaterals (Fig. 4a), compared to the average 6.45 days/well (Fig. 4b) for the less complex wells.

Since drilling started, Petrozuata has significantly decreased its drilling and completion costs. It says costs for a single lateral well have decreased to about $700,000 from $1 million at the beginning of the project. Drilling and completing the more-complex well geometries has decreased to $1.2 million/well from an initial $1.7 million/well.

Petrozuata orients the horizontal laterals based on extensive 3D seismic coverage and also uses petrophysical information obtained in the vertically drilled stratigraphic wells. It drills the fishbones about 500 ft apart with a length of about 1,600 ft each. Closer spacing has led to washouts, it says.

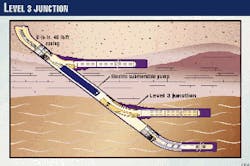

In some wells, Petrozuata has installed Level 3 (Fig. 5) and a few Level 4 junctions. It determines the downhole pump location based on the placement TVD of the lower lateral.

Petrozuata drills the wells with polymer mud and encounters large loses of fluid to the formation. Initially, it attempted to recover the fluid by a vacuuming process with coiled tubing but has now gone to recovering it during producing operations.

Petrozuata says it has not lost a single bottomhole assembly while drilling. To free stuck pipe, its procedure is to allow the fluid level to drop until balanced hydrostatic pressure releases the stuck pipe.

Cuttings and drilling fluid are segregated during the batch drilling operation. Cuttings and fluids from the productive interval go to a drying pit at the well site and are later moved to a dewatering plant. The dried cuttings are mixed and buried in clay-lined borrow pits used during the project construction phase. Each area is reclaimed to its natural habitat. Fluids are treated and disposed of in injection wells along with produced fluids from the production operation.

In all wells, Petrozuata obtains a formation resistivity from a logging-while-drilling tool placed about 30 ft above the bit. Petrozuata drills with polycrystalline diamond compact (PDC) bits.

Some world drilling records claimed by Petrozuata include:

- Drilled 22,707 ft in 176.75 hr with a 16-in. S3SJ4 bit.

- Drilled 11,681 ft in 112.5 hr with a 121/4-in. MPSFJ4 bit.

- Drilled 34,743 ft in 189.5 hr with an 81/2-in. FM2661 bit.

- Drilled 17,031 with an 8-in. A800 Power Pack positive-displacement motor (PDM).

- Set longest 7-in. liner in a horizontal lateral-6,604 ft (from liner shoe to 95/8-in. casing shoe).

- Set longest 51/2-in. liner-7,014 ft (from liner shoe to 95/8-in. casing shoe).

The most feet it has drilled in one well is 37,211 ft.

Well sites

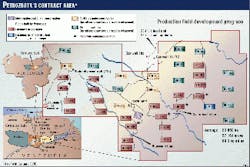

Petrozuata has designed each well pad to have up to 12 wells but does not necessarily drill all wells at once. For flexibility, it builds both eight and four-well production manifold skids.

Petrozuata originally planned to use downhole electric submersible pumps (ESPs) during the early life of each well because of their higher pumping capacity. But has started installing top-drive progressing cavity pumps (PCPs) because this technology can now handle higher rates (Fig. 6). Through mid-January, it had equipped 102 wells with ESPs and 9 with PCPs.

To date, most wells produce very little water, since Petrozuata estimates that initial water saturation in the producing sands is only about 8%. The produced fluid gravity from the formation ranges from 8-10° API, and Petrozuata is increasing the fluid gravity into the flowlines to about 16° API by injecting diluent both downhole and at the wellhead.

Currently, it adds a 30° API Mesa crude, about 37-38% of the total produced stream, pumped from the coast through its 20-in. pipeline. It injects about 25% diluent downhole while the rest is added at the wellhead.

After completion of its upgrader, a 47° API naphtha will replace the Mesa crude. Because the naphtha is lighter, it will only represent about 22% of the total stream. Petrozuata's facilities allow naphtha diluent to be injected downhole, at the wellhead, or in the main process station..

The company's project also takes advantage of emerging multiphase technology. In the field, it has installed 23 multiphase meters and seven 2,000-hp multiphase pumps.

Agar Corp. Inc., Houston, multiphase meters (Fig. 7) allow Petozuata to obtain more-frequent well tests, and the Bornemann twin-screw multiphase pumps (Fig. 8) eliminate the need to install gas separation and handling equipment at the well pads.

Installations costs are about $250,000 for each the multiphase meter and $1 million for each multiphase pump.

Petrozuata produces sufficient associated natural gas to generate all its own electric power at the main production facility. The wells produce with an average 100 scf/bbl GOR, although the formation GOR averages about 70 scf/bbl.

Petrozuata has completed its main field production station except for storage tanks being built by Sincor. That company will use Petrozuata's pipelines to deliver its production to its export terminal at Jose and obtain diluent. Sincor expects its upgrader to start in February 2002. Until then, it will continue to batch Mesa crude for use as its diluent.

Pipeline capacities are 125,000 b/d for the diluent pipeline and 530,000 b/d of 17° API for the produced fluid pipeline. The current plans indicate that the pipeline will have some spare capacity when both Petrozuata and Sincor are on production. Petrozuata will be transporting 120,000 b/d of crude mixed with 50,000 b/d of diluent while Sincor will have 205,000 b/d of crude mixed with 75,000 b/d of diluent, for a total throughput of 460,000 b/d.

Each operator plans to send the production in batches sized about 550,000 bbl from Sincor and 350,000 bbl from Petrozuata.

Ecology

One interesting aspect of Petrozuata's operations is the reforestation of the contract area with eucalyptus trees. Petrozuata expects this project to create 150-250 seasonal jobs for people in the Zuata area, as called for in its contract, and also reduce Venezuela's wood imports.

Currently, it has finished three seasons of plantings of about 5,000 acres and plans eventually to plant a total of 25,000 acres. Petrozuata indicates the trees are ready for harvest in about 7 years after planting the seedlings.

In 1999, Petrozuata planted 1 million trees and plans to plant 2.15 million trees on 3,500 acres in 2000.