Petrochem demand to lag supply until 2002-03

Petrochemical capacity utilization in the US, Western Europe, and Asia, measured as a percentage of nameplate capacity, will rise to a peak in the mid-90% range by 2003, according to a price and profitability outlook analysis by Chem Systems Inc., Tarrytown, NY.

"The new capacity coming on stream over the next 2 years in North America, the Middle East, and Asia is expected to put downward pressure on the industry, with lower-than-average margins over the next year or two, before demand is expected to catch up with supply," said Chem Systems.

"A major driving force for the projected strength in the industry is buoyant demand in Asia, which has recovered from the economic crisis much faster than anticipated. The delay in the construction of projects in China is also a factor."

Product analyses

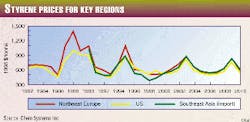

Regarding specific petrochemical products, Chem Systems says the rate of styrene capacity expansion in the three key regions will likely lead to weak margins and relatively low prices in the immediate term (see chart). The outlook for paraxylene is similar.

Chem Systems also studied the outlook for the US petrochemical sector. The firm expects US ethylene consumption to grow an average 3.2%/ year through 2010.

Operating rates will hold steady at 90-92%, says Chem Systems, before increasing to 94% by 2003, "resulting in the next industry fly-up."

At 3.5%/year, the growth rate for propylene consumption is expected to exceed that of ethylene, because poly- propylene demand growth will outstrip increases in polyethylene use.

"An additional 2.8 billion lb/year of propylene will be required to be recovered from refineries for chemical use through 2003 [in order to meet polypropylene demand]. Fortunately, more propylene is being produced in refineries with new catalytic cracking catalysts."

"Relatively slow growth is projected for other major derivatives [such as] acrylonitrile, propylene oxide, cumene, isopropyl alcohol, and oxo-alcohols," said Chem Systems.

Butadiene demand growth will average only 1.7%/year through 2010, predicts the company. "The US, which currently imports about 700 million lb/year [of butadiene], is expected to become self-sufficient early in the next century, as production as a coproduct from ethylene plants is projected to increase faster than demand."

Chem Systems predicts US benzene use to increase 2.4%/year, with similar rates expected for each of its major derivatives-styrene, cumene, and cyclohexane. "Although there is ample benzene capacity, the US is expected to remain a net importer, as low-cost product is expected to continue to be available."

US paraxylene production will grow at only 2.3%/year through 2010, predicts Chem Systems. And, although US polyester output will rise 4.8%/year, US exports of purified terephthalic acid and paraxylene will decline as a result of capacity build-up in Asia.