US oil, gas industry enhances health, safety, environment

Oil and natural gas products have raised our standard of living and helped make us freer, safer, and more comfortable than any people at any time in history.

They-and the facilities that bring them to us-are also increasingly compatible with a clean, safe environment. Companies have steadily reduced emissions, minimized and recycled wastes, and upgraded workplace safety.

As a result, by almost every measure, the adverse impacts of oil and gas have dramatically lessened over the years, even as their expanded use has helped foster the greatest economic expansion in memory.

Improving air quality

Good air quality is important to the US oil and the natural gas industry, just as it is to all Americans. Everyone wants the benefits of petroleum products but not at the expense of cleaner air.

Fortunately, as US Environmental Protection Agency (EPA) statistics show, Americans are enjoying steadily improving air quality. Industries have reduced "criteria"1 pollutant emissions, and pollution concentrations measured in the air are lower.

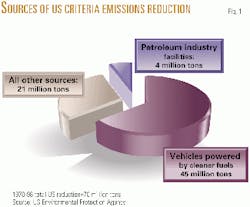

Moreover, cleaner cars, fuels, and industry facilities and operations make up the lion's share of this progress: Together, they account for about 70% of total emission reductions nationwide since 1970.

Our desire to live where we want to live and get where we need to go increases both the number of the nation's automobiles and the demand for energy.

But even though we more than doubled the miles we drove during 1970-1998, total highway vehicle emissions have declined by 41%, according to EPA.

Keying this improvement has been advances in vehicle and fuel technology. Government data show that the reduction in highway vehicle emissions has exceeded the reduction in emissions from all other sources (Fig. 1).

Equally important, despite expected future growth in automobile use, emissions will decline even further.

A new car, built today to EPA's new, more-stringent tailpipe standards and operating on the new, lower-sulfur gasoline, will produce less than 4% of the tailpipe emissions of a new car built in the mid-1960s prior to government regulation.

Gasoline's future

Technology is key to environmental progress. One of many promising new energy technologies, fuel cell-powered cars and trucks, could dramatically increase energy efficiency while virtually eliminating emissions.

The development of this technology may eventually lead to a phase-out of vehicles powered by the internal combustion engine, but it won't necessarily mean replacement of gasoline.

Indeed, gasoline could be the most practical energy source for fuel cells. Instead of being ignited and burned, gasoline in a fuel cell engine would be chemically processed to release hydrogen. The hydrogen would then be combined with oxygen to produce electricity for powering the vehicle.

With help from the oil and gas industry, prototypes of this technology have already been developed.

The big advantage of using gasoline in fuel cell engines? Its use avoids the necessity of investing billions of dollars in new fuel-distribution facilities. Today's gasoline pipelines, terminals, delivery trucks, service stations, and other retail gasoline outlets could continue serving customers' needs.

Industry facilities emissions

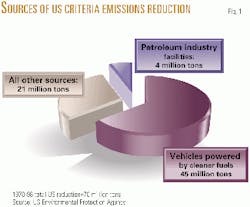

Not only are today's fuels cleaner, oil and gas industry facilities are also helping improve air quality for workers and people in surrounding communities. Refineries and exploration and production operations have substantially cut their criteria pollutant emissions, decreasing them by 69% from 1970 to 1998 (Fig. 2).

Storage and transport operations, including service stations and distribution terminals, are also cleaner. For example, many service stations now have specially equipped pumps that reduce the loss of fuel vapors during vehicle refueling.

From 1985 (the first year EPA statistics were available for this category) through 1998, criteria pollutant emissions from fuel storage and transportation declined by 20%.

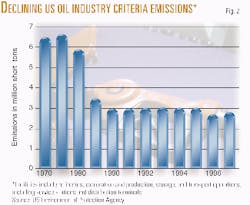

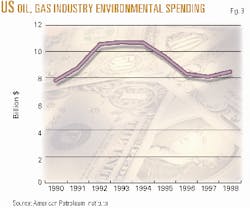

Under EPA's Toxics Release Inventory program, refinery releases, which consist mostly of air emissions, have followed the same pattern. During 1988-97, releases of these emissions fell by 41% (Fig. 3). Emissions of benzene and other elements classified as carcinogens dropped 51%.

Currently, EPA data show that refineries contribute less than 3% of all of the nation's toxic releases.

Protecting water

Clean water is a vital resource that the oil and natural gas industry has been working to protect in many different ways-from improving the designs of oceangoing tankers to upgrading underground storage tanks.

Yet the industry is concerned about more than preventing pollution. It also seeks to enhance water environments near its operations and even extends usable local water supplies by providing water from oil production operations for irrigation and for consumption by wildlife and livestock. For example, one company in California provides millions of gallons of water from its oil wells to help grow grapes, citrus, almonds, and pistachios.

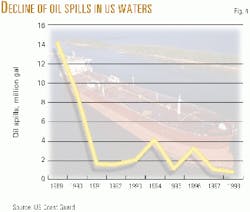

Because of the industry's efforts to keep oceans and other waterways clean, much less oil is spilled, and images of oiled beaches are rare today. US Coast Guard data show that less oil was spilled into US navigable waters in 1998 than in any year since 1980.

In the 5-year period, 1994-98, about two-thirds less oil was spilled than in the prior 5 years, 1989-93 (Fig. 4).

In 1990, Congress unanimously passed the Oil Pollution Act, which established new requirements to help reduce oil spills from tankers and other vessels. Since 1991, there have been no large spills greater than 5,000 bbl from oil tankers in US waters (Fig. 4).

Nearly half of the world's seaborne trade consists of crude oil or petroleum products, including more than half of the crude oil Americans consume. The tankers that move large volumes of crude oil across the seas are the largest ships ever built. The biggest of them are more than a quarter of a mile long.

To prevent or limit the size of oil spills, single-hull tankers are being phased out and replaced with double-hull tankers. Worldwide, more than 700 double-hull tankers were built and put into service throughout the 1990s, more than 500 within the past 4 years. By 2015, all tankers operating in US waters will have double-hulls.

Protecting groundwater is another major priority.

Before sale to consumers, gasoline is often stored in underground tanks, of which there are about 825,000 in the US regulated by EPA. API member companies own about 7% of them.

Unless underground tanks are properly equipped, maintained, and monitored, fuel can leak or spill, threatening contamination of groundwater. By the end of 1998, all such tanks were subject to more-stringent federal regulations. These rules require enhanced corrosion protection, monthly leak monitoring, and special equipment to prevent overfilling and spills.

Under these regulations, API member companies upgraded about 60,000 tanks at more than 20,000 locations at a cost of $1.2 billion.

Recycling, conservation

The oil and natural gas industries promote recycling and conservation to extend the uses of products and enhance the environment. Companies are cutting energy consumption, reducing and recycling wastes, using renewable fuels, developing wildlife sites and conservation programs, planting forests, buying back older, gas-guzzling automobiles, and restoring land affected by industry operations.

Out-of-the-box thinking has advanced conservation in sometimes-unlikely ways. For example, one company has created artificial reefs out of discarded auto tires. Another has converted tank sludge into fertilizer used to grow orange, mango, and banana trees.

Recycling motor oil. Petroleum companies have been at the forefront of the nation's used-motor-oil collection programs.

API members and their independent dealers now operate more than 12,000 drop-off collection centers in the US, including service stations and quick-lube locations. They collected more than 80 million gal of used motor oil during1991-96.

The industry recycles about 60% of all the motor oil in this country, including virtually all that is collected at service bays. Just 2 gal of reprocessed motor oil can generate 36 kw-hr of electricity. That's enough to run the average household for a day, cook 48 meals in a microwave, blow hair dry 216 times, or operate a television set for 180 hr.

The US oil and gas industry is also encouraging used-motor-oil recycling worldwide. For example, one API member company operating in the Pacific region regularly picks up used motor oil in Fiji and the neighboring Cook Islands, recycling it as burner fuel.

The industry also helps educate the public about the importance of used oil recycling and has encouraged states and municipalities to develop their own programs, increasing the convenience for do-it-yourselfers who want to properly dispose of their used motor oil. An API interactive website (www.recycleoil.org), helps direct do-it-yourselfers to the nearest recycling location.

Recycling plastics. It's impossible to count the uses-and reuses-of plastics, which are typically made from petrochemicals derived from oil and natural gas.

Discarded plastic computer housings are converted to pothole filler and highway underlayment. Used PET (polyethylene terephthalate) mineral water bottles become sweaters. And worn out plastics-based carpeting is reborn as outdoor parking bumpers.

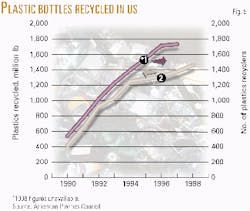

Since 1990, the plastics industry-both as individual companies and through organizations such as the American Plastics Council-has invested more than $1 billion to support increased recycling. The number of plastics recycling businesses has tripled since 1990, now totaling more than 1,700 (Fig. 5).

Reducing environmental 'footprint'

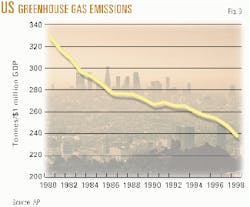

Although global climate theories remain a subject of debate, oil and natural gas companies are closely managing energy use in ways that reduce or control the growth of carbon dioxide and other greenhouse emissions (Fig. 6).

These efforts also result in resources conservation, the reduction of emissions that contribute to urban air-quality problems, and the lowering of energy costs, which are a substantial expense at most industry facilities.

Improvements in energy efficiency include more-efficient lighting, equipment, production processes, energy generation, and facilities to capture and reuse waste energy. For example, by switching to energy-saving lighting, one oil and gas company is saving up to 800 lb/year of carbon dioxide emissions at each of its retail outlets.

Many oil and gas companies are participating in EPA's Green Lights, Energy Star, and Natural Gas Star voluntary programs to increase energy efficiency and reduce greenhouse gas emissions (OGJ, Aug.28, 2000, p. 75).

Finding and producing oil and gas is a major industrial undertaking that can affect the surrounding environment. But improved technology can shrink the area touched by operations, greatly reducing potential environmental impacts. Two examples are three-dimensional seismic imaging and controlled, directional drilling.

Three-dimensional imaging provides better information about the likelihood of oil and gas being found in a particular location, thus avoiding unproductive drilling. Exploration teams get information by reading reflected sound waves generated by ships or trucks equipped with vibrators, explosives, or air guns specially designed for underwater use.

Sophisticated computer technology translates the sound patterns into 3D views of rock formations, which can help geologists better assess the prospects of oil recovery.

Directional drilling allows more wells in less space, reducing the size and number of drilling pads and the number of offshore platforms. Less area is disturbed. Drilling can be directed horizontally or in any direction needed to find oil and gas deposits.

Safer workers

Oil and gas companies are concerned about the safety of their employees as well as the impact of their operations on surrounding communities.

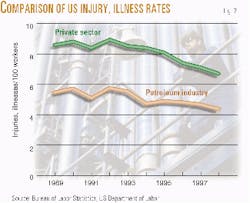

Although work in the petroleum industry is often physically demanding and involves heavy equipment or high temperatures and pressures, the job-related illness and injury rate for the industry's workers is well below that of the US private sector as a whole (Fig. 7).

During 1989-98 (the most recent 10-year period with available data), the industry illness-injury rate declined by 20%. Job-related fatalities also declined-by 11%-from 1992 (the year the US Bureau of Labor Statistics began its fatality census) through 1998.

Investing

Meeting America's needs for oil and gas requires substantial investments to protect our environment and that of future generations.

During 1990-98, the US petroleum industry spent almost $83 billion on the environment-including about $8.5 billion in 1998 (Fig. 8). Spending on the environment that year was more than EPA's total budget, and it more than doubled the net income of the top 200 oil and natural gas companies.

The refining sector typically has been responsible for half or more of all industry environmental expenditures. This reflects investment over the past decade-and especially during the mid-1990s-in new equipment and facility improvements to make new, cleaner-burning fuels.

The industry has spent vast sums to reduce pollution, yet technological improvements and competition have helped keep prices in check. Adjusted for inflation, gasoline in the 1990s was the most affordable it has been since prices were first systematically recorded early in the 20th century.

Note

- According to EPA, "criteria" pollutant emissions include carbon monoxide, volatile organic compounds, nitrogen oxides, sulfur dioxide, lead, and particulates. Some of these emissions combine in the atmosphere to create ozone smog.

The author-

Red Cavaney is API president and CEO. He also has served as president and CEO of the American Paper Institute, American Forest & Paper Association, and the American Plastics Council. Cavaney served in the White House on the staffs of presidents Nixon and Ford, as special assistant to the president and director of the advance, and in the Reagan White House as deputy assistant to the President for public liaison.

Cavaney holds a BA in economics and history from the University of Southern California.

OSHA proposal worries US drilling industry

A proposal by the US Occupational Safety & Health Administration to redefine lower back pain as a compensated injury, rather than a medical symptom, could cost the land drilling industry billions of dollars and might drive some contractors out of business.

That's the view of a drilling safety officer with a leading US drilling contractor.

Although OSHA officials downplay the potential price, that proposal would prove more costly to US industry than the original legislation that created that agency in 1970, said Bill Hedrick at the annual meeting of the International Association of Drilling Contractors (IADC) in Houston in late September. Hedrick is manager of health, safety, and environmental issues for Rowan Cos. Inc. and chairman of the IADC's ergonomics subcommittee.

OSHA proposal denounced

Hedrick denounced the OSHA proposal as a political sop to organized labor, brought forward by the Clinton administration in November 1999 after the issue had spent years on the backburner of potential OSHA actions.

Officials at OSHA estimate total industry compliance would cost a maximum $10 billion. But the real costs will be 8-15 times higher than that, Hedrick said.

Much of that expense would be in addition to state-administered workman compensation programs, he said. "As it's now written, it will drive people out of business," Hedrick told reporters.

OSHA officials claim additional worker protection is necessary because industry has not done enough to reduce musculoskeletal disorders, such as back injuries from improper lifting, or repetitive stress and strain that causes carpal tunnel syndrome.

But when IADC filed Freedom of Information Act requests for the statistical information upon which OSHA based its conclusions, agency officials could not supply documentation, Hedrick said. The industry, however, can document a continuing downward trend in the number of drilling accidents for several years.

Opponents of the proposal say that OSHA's definition of the injury is too broad and that qualifications are too general for the "health care providers" that the agency would allow to diagnose such injuries. In one recent test of physicians who had graduated from medical schools in the last 5 years, Hedrick reported, 82% of the participants could not meet competency standards for diagnosing musculoskeletal disorders.

Fraud concerns

OSHA officials contend that only 2% of all workers would make fraudulent claims of debilitating pains that could not be verified by X-rays or other medical tests.

But opponents claim the proposal provides financial incentives for fraudulent claims or at least extended recoveries by requiring companies to maintain workers at 90% of their take-home pay, plus full benefits, for the length of treatment. Since many people also carry disability insurance that would make their house and car payments while they are off work, Hedrick said, "some people could actually increase their income" through such an injury claim.

The new regulation would apply to workers on land rigs, but not those on offshore rigs that are regulated by the US Coast Guard and the Minerals Management Service, under a memorandum of understanding with OSHA that has already been tested in court.

It also would not apply to laborers employed in agriculture, construction, or marine operations in shipyards, marine terminals, or longshoreman jobs.

The IADC is joining with other industries in opposing the proposal. "Dentists really hate this thing, and they have money to fight it," said Hedrick.

He said some industry groups are already preparing a legal challenge if the proposed regulation is activated.