Wellhead growth index aids multistring casing design

A newly developed Wellhead Growth Index (WHI) allows engineers to design multistring casings more effectively.

WHI, which encapsulates annular fluid expansion, provides a simple, practical way to view the severity of the wellhead movement during drilling as well as in the production phase of the well.

This practical index not only helps to quantify the design of the casings under different loads but also increases the cost effectiveness of the casing design.

Due to increased deepwater operations, use of tension-leg platforms, and the drilling of high-temperature, high-pressure wells, it has become necessary to add more casing design parameters. Numerous variables can be taken into account within the design spectrum.

In the casing design envelope, it is imperative to include the behavior of the wellhead system, blowout preventer (BOP), lower marine riser package (LMRP), and riser.

Conventional multistring designs call for calculating the wellhead growth and annular expansion by selecting a particular design at the development stage of the well planning.

Because this does not properly restrict wellhead growth, care must be taken to provide proper surface equipment. However, sometimes the available surface equipment restricts the ability to handle a wide range of wellhead growth.

A constraint is therefore imposed on wellhead growth, and the optimization is carried out to design the complete casing for all the casing strings with minimum cost.

System selection

The ability to optimize the complete casing design depends on the availability of alternate means of meeting the well plan. These alternatives include the number of casing strings and casing seats, or possible techniques that can be used given the equipment limitations.

Identifying alternatives consists of obtaining minimum cost for all casing sizes, including wellhead growth. Selection of the optimal casing design requires consideration of various types of thermal and mechanical loads to which casing strings are subjected.

The design of efficient algorithms is guided by a number of general paradigms, including exhaustive search, dynamic programming, branch-and-bound, and the "greedy" paradigm.

The additional constraint of wellhead growth renders a deeper understanding of the concepts involved and the prospect of practical use.

A multistring casing design allows for better factorization of the design process. This requires a generalization of the concept that is well understood in the single-string setting to the more general multistring settings.

Relational specifications to a single-string analysis are sometimes rather cryptic to the uninitiated, and therefore investigating and implementing to broader specifications of all casings simultaneously can be useful.

This article concerns exploitation and modification of the earlier work conducted on the branch and bound algorithm.

Growth index

The intricate nature of relational expressions can also be a hindrance in comparing different designs under certain conditions. WHI was developed to counter this problem.

WHI encapsulates annular fluid expansion and provides a simple, practical way to view not only the casing movement but also the fluid expansion in the annuli during the course of drilling.

It is defined as the ratio of the annular fluid expansion of the casing to the actual volume of the exposed segment above the top of the cement.

The annular fluid expansion includes the unconstrained volume change and the annulus volume change due to annular pressures.

Wellhead growth gives an estimate of the circumferential and axial strain on the casing strings. With the circumferential and lateral strains, the total volume of the expansion of all casing string for all casing segments are given by Equation 1 (Equation box).

Equation 2 gives the total area of the annulus cross-section for each casing string.

Using Equations 1 and 2 with approximations, Equation 3 gives the WHI for multiple casing strings.

WHI gives a quantitative predictive capability to interpret the results of these calculations. The higher the WHI, the higher will be the severity of the casing design involved.

Calculation of WHI at different stages of the casing design will aid in comparing the relative rigorousness of the overall casing design.

Case study

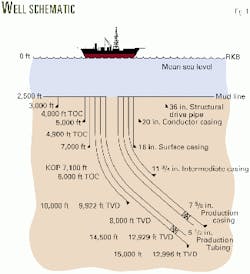

This study covers a casing design for Well A, an offshore deviated well with a water depth of 2,500 ft, incorporating typical complex subsea well problems (Fig. 1).

The initial design calls for a structural drive pipe to a depth of 3,500 ft. This is followed by running a 20-in. conductor casing string to a depth of 5,000 ft with Section No. 1 using a 169 ppf, X-56 casing string to a depth 4,000 ft, and Section No. 2 using 133 ppf, X-56 casing. The 16-in. surface casing is to a depth of 7,000 ft with one type of 84.80 ppf, J-55 casing.

The intermediate 11 3/4-in. casing is to be landed with the following two sections: Section No. 1-88 ppf, Q125 casing; Section No. 2-88 ppf, P110; and the final section 75/8-in. production casing to depth of 15,000 ft.

It consisted of two sections with Section No. 1, 33.7 ppf, P-110, and Section No. 2, 39 ppf, P-110. The cement top for each casing is given in Fig. 1.

A potential producing formation is expected to be found at about 14,500 ft. Production tubing of 51/2 in. is needed for the final completion with packer. The estimated production data are given as follows:

- Oil production = 10,000 b/d.

- Gas production = 80 MMcfd.

- Wellhead pressure = 4,000 psi.

The structural constraints impose a limitation on the wellhead growth in both directions of no more than 6 in. during the life of the well besides other essential mechanical and load constraints.

Casing design, analysis

The structural pipe is not included in the system under consideration. The initial design analysis yielded a wellhead growth of more than 6.1 in. The optimization with the wellhead growth was carried out and yielded the following casing design with the wellhead growth of 6 in. (Table 1).

Table 2 gives the annular expansion volume calculated for each region of the annulus with the original casing design as well as with the optimized casing design.

Total cost of the original combination of the string is $781,810. With the optimized casing design, a cost saving of $35,378 is realized with this procedure and design.

This complex subsea well configuration has induced more critical annuli fluid expansion conditions which limited cost savings for a given wellhead growth restriction. This is clearly apparent from the Wellhead Growth Index.

Bibliography

Robello, G.S., and Gonzales, A., "Optimization of Multistring Casing Design with Wellhead Growth," SPE paper 56762, presented at the SPE Annual Technical Conference, Oct. 3-6, 1999, Houston.

The authors

G. Robello Samuel is a principal technologist with Landmark Graphics, Houston. He has worked more than 9 years as an executive engineer (drilling) with Oil & Natural Gas Corp. of India. Samuel holds a BS in mechanical engineering from the University of Madurai, India, and has an MS in mechanical engineering from the College of Engineering Guindy, Madras. He also holds an MS and PhD in petroleum engineering from the University of Tulsa. Samuel presently serves as a technical editor on the SPE Editorial Review Committee and member of the Steering Committee for ASME-Petroleum Division Conferences. He is also the chairman of the SPE Multilateral Technology Technical Interest Group and is member of the SPE Well Logging Committee.

Adolfo C. Gonzales is a senior principal consultant for Landmark Graphics Corp., Houston. He graduated from San Marcos University, Lima, with a geological engineering degree in 1979. His senior consultant responsibilities include design analysis for technically complex wells and also responsiblity for casing and tubing design training. Prior to joining Landmark, Gonzales worked for Baker as a geoscientist in the areas of formation evaluation, formation pressure evaluation, and wellbore wettability. He is a member of SPE.