New technology improves portable well testing units

The availability of 0-100% water-cut measurement devices and accurate flow measurement meters has improved the results of portable well testing units in the Kern River field in California.

Two portable well testing trailers were built and their performances over the last 2 years were compared with conventional automatic well-testing measurements. The gauge factor of 2.37% obtained in this comparison is an acceptable performance for the portable units.

Well testing

Proper evaluation of a large producing field with numerous wells requires accurate and frequent well tests. These tests allow an operator to optimize a field's performance by shutting-in wells, working them over, or stimulating them.

Conventional well testing involves gravity separation of the production stream into oil, water, and gas. This requires pumps, tanks, heaters, and pressure vessels and putting each well on test usually for several hours.

The industry has made many attempts at making well testing more accurate and consistent.1 One advance made during the past 5 years has been improved multiphase measurement technology for on line determination of oil, water, and gas volumes.2

Oil-water monitoring

Portable systems can lower well testing costs because one system can be used to test many wells. But these systems require components that are compact and perform well in a variety of produced fluids.

A truely 0-100% water-cut device is an essential component of the portable testing unit. For this reason, the first step in designing the Kern River units was to evaluate new oil-water monitoring devices in Texaco's Kern River oil-water test loop.3

The test loop can be used to mix lease oil and water to form controlled 2-80% water-cut emulsions. Kern River oil at various sites has a 12.5 degrees API gravity while the water salinity is 240 ppm and produced fluid temperature is 140-160 degrees F.

After evaluating several devices in the loop, Texaco selected an Agar Corp., Houston, (Agar OWM 201) microwave-based, oil-water monitor for the portable testing units.

Reference 3 describes the device in detail.

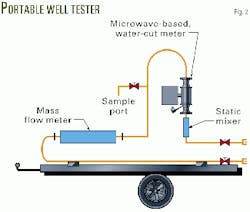

Portable well testing trailers

Figs. 1 and 2 show the design of the portable testing trailers. The major components are the microwave-based, oil-water monitor and the Coriolis mass flow meter.4

Texaco evaluated the accuracy of the portable units against conventional automatic well testing sites, selected because of their well test histories. Historical gauge factors and grab samples established the accuracy at these sites.

Each automatic well test site has a 100-bbl tank with a conical bottom section. During the testing, production from a well was routed to the tank for 2 hr and allowed to separate before fluid was pumped out from the tank bottom.

A capacitance water-cut probe established the oil content of the tank and a Coriolis-based meter provided the volumetric readings.

Flexible hoses connected the portable well testers to the test header and each well was allowed to flow through the portable unit for 15 min. Water was continuously monitored on line and a Coriolis-based meter determined the flow rate.

Produced oil and water volumes were then calculated with the flow-integrated water cut and flow data.

For well testing, the portable units can also be connected directly to the wellhead.

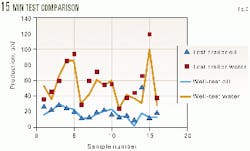

Fig. 3 compares the portable unit's results with readings from the test tank. In this case, 16 wells were producing 40-130 b/d of total fluid.

Average water cut determined from a 2-hr tank test was 74.24%, while a 15-min test through the portable unit indicated a 71.86% water cut. This comparison resulted in the 2.37% gauge factor, previously mentioned.

The shorter test time of 15 min is another benefit of the portable unit.

Field applications

Over the last 2 years, the two portable well testing trailers have been used in various field trials.

In one application, the units assessed the gauge factor for a newly acquired 96-well property, without a proper well testing facility. The mobility of the portable well test units allowed these wells to be tested quickly.

These tests were not conducted on line because of a small amount of free gas. To remove the free gas, production was first sent to a test tank before it went through the portable well test unit.

Fig. 4 shows the test results that started on June 15, 1999. The initial 10% gauge factor was reduced to 2% within 5 days.

In another application (Fig. 5), the portable unit was used to determine the reason for production declining at a 46-well site. This decrease in the production had precipitated a number of workovers to find the source of the downhole problem.

In late January 1999, one portable well test unit quickly revealed that the decrease in production was due to a vacuum problem, caused by improper seating of a test valve. The problem sent fluid away from the test tank.

Once the problem was diagnosed, production was quickly returned to normal levels.

Observations

The portable well test trailer cost, about $40,000, is considerably less than the $250,000 cost for a conventional automatic well test facility, and its mobility allows an operator to utilize it at many sites, thus reducing the capital costs for a field.

More importantly, the on line measurement capability of the portable units allows the operator to reduce substantially the time for a well test. A large number of wells can then be tested more frequently, reducing the cost per well test.

Because of the mobility of the tester and more frequent testing, an operator can detect production problems more quickly, preventing unnecessary workovers.

Free gas is the main problem with the portable well test unit. Free gas can affect the performance of the flow rate meter and oil-water monitoring device. If free gas is present in the production stream, one needs a separator or diverting vessel for removing the gas.

A portable well testing system suitable for production streams containing free gas is currently undergoing field tests at Kern River.

Changing fluid properties are another problem with the portable tester. Fluid properties, such as salinity, API gravity, temperature, etc., can affect the performance of both the oil-water monitor device and Coriolis-based flow meter and their overall accuracy.

It should be noted that the overall accuracy of the oil or water flow rate is a product of flow measurement and water-cut accuracy. The devices selected for a portable well test system, therefore, must be able to perform in a variety of fluid conditions without the need for frequent field adjustments.

References

- Tuss, B.M., and Kendrick, R.A., "Well Testing Systems: Designing for Accuracy," Paper No. 24806, SPE Annual Technical Conference and Exhibition, Washington, Oct. 4-7, 1992.

- Mehdizadeh, P., "Multiphase Meters-Delivering Improved Production Measurements and Well Testing," Petroleum Engineer International, May 1998.

- Mehdizadeh, P., "Better Net Oil Monitoring," Hart's E&P, August 2000.

- Liu, K.T., and Kouba, G.E., "Coriolis based net oil computers gain acceptance at wellhead," OGJ, June 27, 1994, p. 42.

The authors

Steve Means is a data analyst for Texaco Inc., Bakersfield, Calif. He has worked in automated well-testing measurement and monitoring for more than 24 years.

Parviz Mehdizadeh is a consultant with Production Technology, Phoenix, Ariz. He provides clients with technical advice on multiphase measurements and marketing in the oil industry. He previously worked for Conoco Inc. and Agar Corp. Mehdizadeh has a BS and MS in physics and a PhD in chemical engineering and materials sciences from the University of Oklahoma. He is a member of SPE and has served on various API standardization committees.