Alliance updates performance of new dewaxing technology in Louisiana refinery

To improve distillate yield and quality, Pennzoil-Quaker State Co. (PQS) recently adopted and implemented the proprietary MAKFining isomerization dewaxing technology (MIDW) in its 7,000 b/d Shreveport, La., refinery.

MAKFining is a global alliance among ExxonMobil Corp., Akzo Nobel Catalysts BV, Kellogg Brown & Root, and TotalFinaElf, which markets and licenses a suite of refining technologies.

MIDW choice

Cees P. Smit, a general manager of Akzo Nobel, reported the choice and performance of PQS's MIDW application in a recent issue of Akzo Nobel's newsletter. PQS chose the MIDW process because it wanted to maximize distillate yields and produce a product with good pour point characteristics and low sulfur. The unit has been operating successfully since early November 1999.

PQS's application is the second commercialization of the new-generation MIDW catalyst in a single-stage service. The technology, first commercialized in 1990, was developed by the former Mobil Technology Co., Paulsboro, NJ, using its proprietary catalytic process technologies.

PQS upgraded its existing hydrodewaxing unit from ExxonMobil's distillate dewaxing technology (MDDW) to MIDW. The upgrade required no capital investment, only a catalyst change to a proprietary ExxonMobil MIDW catalyst, said Smit.

Performance

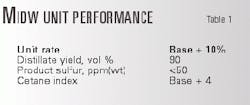

MIDW isomerization technology results in a distillate yield of more than 90 vol %, Smit said. In comparison, MDDW has a 75 vol % distillate yield at the equivalent distillate pour point. The MIDW diesel product's cetane and T95 properties are also significantly better than those from conventional hydrodewaxing.

The technology preferentially isomerizes paraffins, reducing the diesel pour point while keeping the high-cetane components in the diesel product. Table 1 shows the expected improvement in PQS's distillate yield and quality as a result of its application last year.