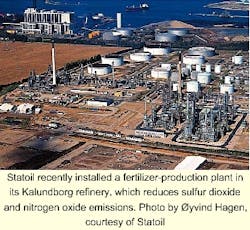

Denmark refinery gets first-of-a-kind fertilizer plant

A new fertilizer-production facility, the first of its kind, began operations at Statoil AS's Kalundborg refinery in Denmark in September. .

The plant converts refinery sour gas and ammonia, both by-products from crude-oil processing, into liquid ammonium thiosulphate (ATS), an agricultural fertilizer.

Denmark's Haldor Topsøe AS developed, built, and delivered the DKK 70 million ($8.3 million) facility to Statoil, which owns and operates the facility as an integrated part of the refinery.

Sulfur conversion

Refineries typically convert hydrogen sulfide from their various streams into sulfur, which is then used for the production of sulfuric acid. The refinery uses energy to convert the remaining hydrogen sulfide and ammonia into sulfur dioxide (SO2) and nitrogen oxides (NOx) to be released to the atmosphere.

Before this fertilizer plant started up, Statoil sold approximately 4,000 tonnes of sulfur by-product each year to chemical companies. The remaining by-product, about 275 tonnes/year of hydrogen sulfide, was emitted as 550 tonnes/year of SO2.

The new facility allows all the sulfur from the refinery to be converted into ATS, reducing emissions and saving energy. The refinery achieves a total refinery emissions reduction of 60% of SO2 and 30% of NOx.

With respect to energy, the refinery saves fuel by eliminating the conversion of the remaining hydrogen sulfide and ammonia. The new process also requires less electricity and produces more steam than the present sulfur-production processes. Haldor Topsøe says its process consumes less energy than other known ATS production methods.

With the new ATS plant, the Statoil refinery converts about 99.95% of its hydrogen sulfide and practically 100% of its ammonia into a 60% aqueous solution of ATS. The process requires more ammonia than is available from the refinery and thus Statoil purchases the required balance.

Annual production of ATS is expected to reach 15-27,000 tonnes, said Statoil, depending on the feedstock used by the refinery. The Dan Gødning Co., Fredericia, Denmark, will market this output, mainly to Northern Europe, including Denmark.

The Danish Energy Agency supported this project with a grant of DKK 12 million.