Governments, operators eyeing effects of synthetic-based drilling fluids

By yearend, rig operators in the UK Continental Shelf will have reduced to zero the discharge of their synthetic-based drilling fluid contaminated cuttings.

To comply with government requirements, operators have had to reduce discharges by at least 20% each year until the 2001 deadline. Most of the rest of Europe has already adopted a zero or limited-discharge approach.

In the US, the Environmental Protection Agency (EPA) has taken a more pragmatic approach by including the potential polluting effects of not only the discharge of cuttings into the sea but also any fuel use or air emissions from barging, reinjection, or cuttings disposal on land.

The US is currently evaluating the various options with regard to synthetic fluids, but it seems likely that some discharge will be permissible based on a fluid's marine toxicity and biodegradation as well as taking into account its respective economic factors.

The final US EPA proposals are scheduled to be in place by 2001.

Background

Following the 1992 Paris Commission (PARCOM) decision to prohibit more than 1% oil-on-cuttings beginning January 1997, concerns were raised about the environmental acceptability of some synthetic fluids. (The group is now named Oslo & Paris Commission. The organization represents European countries in the area of setting standards and introducing guidelines related to the marine environment.)

Government and industry research found that several synthetic-based fluids used in mud formulations exhibited similar biodegradation profiles to mineral oils offering no apparent benefits, although this was under dispute at the time.

As a result, the UK government decided to reduce the discharge of a number of synthetic-based fluids.

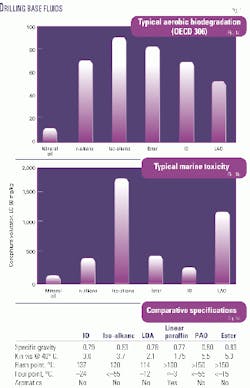

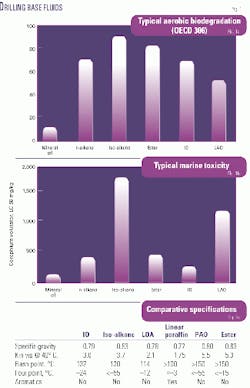

These base fluids included acetal, internal olefin (IO), linear alpha olefin (LAO) linear alkanes, and poly alpha olefin (LAO; Fig. 1).

Esters were not subjected to the same reduction program because of their rapid biodegradation. However, some observers commented that their rapid biodegradation caused anoxic conditions to occur on the seabed that potentially could be more damaging to the marine environment than synthetics which biodegraded less quickly.

Fluid basics

Several chemicals are now used, or have been used, as replacements of conventional mineral oils in invert emulsion fluids. These include:

Esters-These may be produced from vegetable oil by reacting the fatty acid component with an alcohol.

Acetal-These are made from reacting alcohols to produce a monoether that in turn is converted into a di-ether.

Polyalphaolefin (PAO)-These are complex molecules produced from ethylene.

Detergent alkylates (LABs)-Also referred to as linear alkylate benzenes, LABs are intermediates in the production of detergents. They are manufactured by reacting saturated hydrocarbons with benzene. These products are now banned in most countries.

Linear alpha olefin (LAO) and Internal olefins (IO)-LAOs and IOs are the raw materials for the more-complex PAO produced from ethylene. In LAOs, the point of unsaturation is on the first and second carbon molecules of the molecular chain, whereas in IOs the unsaturation can occur anywhere in the carbon chain.

Iso-alkanes-These are a fairly recent development that appear to be bridging the gap between a synthetic fluid and a conventional mineral oil. These products are produced from linear long-chain alkanes that are then converted to branched short-chained alkanes using a hydrogen catalyst under extremely high temperature and pressure.

These products are extremely clean and pure and usually meet US Food and Drug Administration (FDA) standards.

Environment vs. economics

With operators facing additional costs for either reinjection or transportation, cost reviews are inevitable. A key targeted area is the cost of the base fluid.

Several operators feel that synthetic-based oils can be replaced by cheaper grades. Discharges will no longer be permitted; hence, there will be no need to use quality base fluids.

On the face of it, this would appear to be a retrograde step. Many of these synthetic fluids not only meet high marine environment levels, but increasingly they have proved to be beneficial to the working environment by exhibiting very favorable occupational hygiene characteristics.

It is arguable that occupational hygiene standards should be the first priority in selection of a base fluid rather than the fluid's environmental compliance.

In Norway, with the banning of all discharges in 1997, occupational hygiene has received considerable attention. This has caused a move to fluids that have virtually zero aromatics and high flash points (118-130° C.).

In some cases, these fluids are clean and odor-free, being classified as white oils by conforming to FDA standards. In effect, this means they meet US Pharmacopoeia quality. Operators in Norway use these products preferentially.

In the UK, however, there have been moves by some operators to return to products with 1% aromatics with flash points below 80° C. Many of these products were first used in the mid-to-late 1980s when the boom in the use of invert emulsions first took off.

This is a great concern because more-recent research shows that these low-volatility products tend to generate high levels of hydrocarbon vapors.

These must be viewed as a serious threat to the health and safety of rig personnel, as well as increasing the risk of fire on the rig.

Using recovered oil from onshore cuttings disposal operations also presents potential working environmental issues. The recovered oils are not quality controlled and frequently have a particularly pungent odor making them unacceptable for drilling fluid reuse.

Accidental spills are a fact of life in the industry, and with this in mind, products that exhibit good levels of biodegradation should be considered.

Beyond 2000

The industry, especially in the North Sea, has made enormous strides in the quality of invert base fluids used-from diesel in the early 1980s, to the 5-6% aromatics products, through the 1% aromatic products of the 1990s, followed by two generations of synthetics.

It would be wrong to disregard these advances purely on economic grounds. It should be possible to strike a balance between cost considerations, quality, and safety. Products are available which achieve this balance.

There are always trade-offs between different characteristics of a base fluid. For example, a lower viscosity will mean a lower flash point. But there are grades that offer the formulator what he wants without the need to compromise on either health and safety or environmental compliance.

Whether the base fluid is synthetic or mineral oil, there are a number of grades available which meet these criteria at reasonable costs.

The hope is that this critical area of the oil exploration industry will continue to move forward and not backward because of cost pressures. Ongoing dialog between operators, drilling-fluid service companies, and base-fluid suppliers must be maintained. That will ensure that the needs of the working environment and the marine environment are balanced with economics.

The author

Steve Spencer is director of marketing for SIP Ltd., London. He has 25 years' experience in the oil and chemical industries. During that time, Spencer has been involved in drilling and in specialty oils, fluids, and solvents. He has been active in the development of SIP Ltd.'s drilling base fluids business in Europe, Africa, and the Middle East. Spencer holds degrees in business and marketing management from Henley Management College and is a member of the Chartered Institute of Marketing.